Abstract

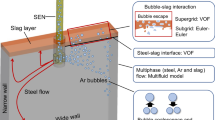

Large bubbles seriously reduce the efficiencies of the interactions between the bubbles and the molten steel, such as energy transfer, momentum transfer, mass transfer and chemical reaction. To reduce the size of the bubbles and increase the gas–liquid interface area, a novel non-intrusive method of bubble refinement was proposed, which only depends on the molten steel flow field controlled by the rotating electromagnetic field. The flow fields of the molten steel for bubble refinement were analyzed, and the corresponding bubble refinement was investigated. It was found that the molten steel formed obvious rotating turbulent flow for bubble refinement under the unidirectional rotating electromagnetic field. However, the large vortex in the center of the molten pool caused by the rotating flow made the bubbles aggregate and coalesce again, resulting in formation of larger bubbles and gas cavity. To suppress the central vortex formation and enhance the bubble refinement, the forward-reverse rotating electromagnetic field for bubble refinement was proposed. The irregular and chaotic flow occurred repeatedly because of alternating forward and reverse rotating in a short period, so that the turbulent kinetic energy and turbulent dissipation of the flow field always remained at a high level which favors bubble refinement. As a result, the bubble diameter can decrease by more than 50% compared to that without electromagnetic field. Furthermore, it is important that this non-intrusive kind of bubble refinement method completely avoids the introduction of non-metallic inclusions caused by intrusive configuration.

Similar content being viewed by others

References

J.M. Su, Z.H. Dou, T.A. Zhang, Y. Liu, ISIJ Int. 60 (2020) 915–921.

A. Kumar, Z.E. Chacko, M. Malathi, K.M. Godiwalla, S.K. Ajmani, S. Ranganathan, Steel Res. Int. 85 (2013) 927–934.

S. Li, X.L. Wei, L.X. Yu, Fuel 90 (2011) 1350–1360.

W.F. Li, R. Zhu, K. Dong, J. Zhang, C. Feng, B.C. Han, X.T. Wu, Metall. Mater. Trans. B 51 (2020) 1060–1069.

M.Y. Zhu, W.T. Lou, W.L. Wang, Acta Metall. Sin. 54 (2018) 131–150.

D.Q. Geng, J.X. Zheng, K. Wang, P. Wang, R.Q. Liang, H.T. Liu, H. Lei, J.C. He, Metall. Mater. Trans. B 46 (2015) 1484–1493.

G. Holzinger, M. Thumfart, Steel Res. Int. 90 (2019) 1800642.

L. Zhao, Y. Pan, H.C. Liao, Q.G. Wang, Mater. Lett. 66 (2012) 328–331.

L. Li, D.C. Wu, G.Y. Liang, Z.B. Sun, Y.L. Guo, J. Alloy. Compd. 474 (2009) 378–381.

S.N. Sahu, A.A. Gokhale, A. Mehra, Adv. Eng. Mater. 19 (2017) 1600745.

T. Fabritius, J. Riipi, M. Järvinen, O. Mattila, E.P. Heikkinen, A. Kärnä, J. Kurikkala, P. Sulasalmi, J. Härkki, ISIJ Int. 50 (2010) 797–803.

N.D. Petsev, L.G. Leal, M.S. Shell, Phys. Rev. Lett. 125 (2020) 146101.

J. Wannasin, R.A. Martinez, M.C. Flemings, Scripta Mater. 55 (2006) 115–118.

L.H. Wang, H.G. Lee, P. Hayes, ISIJ Int. 36 (1996) 7–16.

Y. Liu, M. Sano, T.A. Zhang, Q. Wang, J.C. He, ISIJ Int. 49 (2009) 17–23.

J.Y. Wang, L.G. Wang, J. Hanotu, W.B. Zimmerman, Fuel Process. Technol. 165 (2017) 131–137.

M.C. Díaz, S.V. Komarov, M. Sano, ISIJ Int. 37 (1997) 1–8.

F. García-Moreno, B. Siegel, K. Heim, A.J. Meagher, J. Banhart, Colloid. Surf. A Physicochem. Eng. Asp. 473 (2015) 60–67.

B. O. Hasan, Int. J. Multiph. Flow 97 (2017) 94–108.

T. Yamamoto, Y. Fang, S.V. Komarov, Chem. Eng. Sci. 197 (2019) 26–36.

M. Martín, F.J. Montes, M.A. Galán, Ind. Eng. Chem. Res. 47 (2008) 6251–6263.

Y. Liu, Z.M. Zhang, S. Masamichi, J. Zhang, P. Shao, T.A. Zhang, J. Iron Steel Res. Int. 21 (2014) 135–143.

E.R. Gómez, R. Zenit, C.G. Rivera, G. Ramírez-Argáez, M.A. Ramirez-Argaez, Metall. Mater. Trans. B 44 (2013) 423–435.

N.Z. Wang, X. Chen, J.Y. Yuan, G.Q. Wang, Y.X. Li, H.W. Zhang, Y. Liu, Metall. Mater. Trans. B 47 (2016) 3362–3374.

M. Laakkonen, P. Moilanen, J. Aittamaa, Chem. Eng. J. 106 (2005) 133–143.

M. Laakkonen, P. Moilanen, T. Miettinen, K. Saari, M. Honkanen, P. Saarenrinne, J. Aittamaa, Chem. Eng. Res. Des. 83 (2005) 50–58.

J.H. Ji, R.Q. Liang, J.C. He, ISIJ Int. 57 (2017) 453–462.

Q. Wang, M. He, X.W. Zhu, X.L. Li, C.L. Wu, S.L. Dong, T. Liu, Acta Metall. Sin. 54 (2018) 228–246.

C.L. Wu, D.W. Li, X.W. Zhu, Q. Wang, T. Oleksandr, H. Lei, Acta Metall. Sin. 55 (2019) 875–884.

D.W. Li, Z.J. Su, K. Marukawa, J.C. He, J. Iron Steel Res. Int. 21 (2014) 159–165.

D. Schurmann, B. Willers, G. Hackl, Y. Tang, S. Eckert, Metall. Mater. Trans. B 50 (2019) 716–731.

Z. Yu, Z.Q. Zhang, Z.M. Ren, Z.S. Lei, K. Deng, Acta Metall. Sin. 46 (2010) 1275–1280.

Y.X. Liao, D. Lucas, Chem. Eng. Sci. 64 (2009) 3389–3406.

J. Vejražka, M. Zedníková, P. Stanovský, AIChE J. 64 (2018) 740–757.

J. Solsvik, H.A. Jakobsen, Int. J. Chem. React. Eng. 13 (2015) 477–491.

T.Y. Liu, Y. Sheng, L.H. Han, Q. Liu, J. Chem. Eng. Jpn. 50 (2017) 4–14.

B. Willers, M. Barna, J. Reiter, S. Eckert, ISIJ Int. 57 (2017) 468–477.

K. Mishra, Int. J. Numer. Methods Fluids 69 (2012) 897–908.

Z. Jaworski, B. Zakrzewska, Chem. Eng. Res. Des. 80 (2002) 846–854.

L. Schiller, A. Naumann, Z. Ver. Deutsch. Ing. 77 (1935) 318–320.

Z.Q. Liu, L.M. Li, F.S. Qi, B.K. Li, M.F. Jiang, F. Tsukihashi, Metall. Mater. Trans. B (2015) 406–420.

S. Kumar, D. Ramkrishna, Chem. Eng. Sci. 51 (1996) 1311–1332.

H. Luo, H.F. Svendsen, AIChE J. 42 (1996) 1225–1233.

B.K. Li, F. Tsukihashi, ISIJ Int. 40 (2000) 1203–1209.

C. Martínez-Bazán, J.L. Montañés, J.C. Lasheras, J. Fluid Mech. 401 (1999) 157–182.

K. Wichterle, Steel Res. Int. 81 (2010) 356–361.

Acknowledgements

The authors gratefully acknowledge the financial supports by the National Natural Science Foundation of China (No. U1560207), the National Key R&D Program of China (No. 2017YFB0304402), the Fundamental Research Funds for the Central Universities (No. N2125018 and No. N180915002) and Liaoning Innovative Research Team in University (No. LT2017011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Ly., Liu, Zy., He, M. et al. Flow fields control for bubble refinement induced by electromagnetic fields. J. Iron Steel Res. Int. 29, 575–587 (2022). https://doi.org/10.1007/s42243-021-00627-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00627-w