Abstract

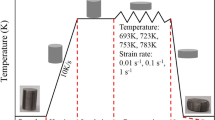

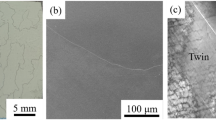

The thermal deformation behaviors of the as-cast and wrought modified IN617 nickel-based heat-resistant alloys at different temperatures (1000–1180 °C) and strain rates (0.01–1 s−1) were studied. The constitutive equation was established to describe the relationship of the flow stress, temperature, and strain rate during thermal deformation. The effect of the thermal deformation conditions on the microstructure evolution of alloys was studied using electron backscatter diffraction. The results revealed that the thermal deformation activation energy of the as-cast alloy was greater than that of the wrought alloy. The dynamic recrystallization (DRX) process is slow at intermediate strain rate (0.1 s−1) due to the comprehensive influence of various factors, such as the critical strain of DRX nucleation and stored energy. The DRX volume fraction increases with the improvement of deformation temperature. The varied dynamic softening mechanisms induce the different thermal deformation behaviors of as-cast and wrought alloys. The dynamic recovery, discontinuous dynamic recrystallization (DDRX) and nucleation at slip zone caused by strain incompatibility in grains were observed during thermal deformation of as-cast alloys. In the process of thermal deformation of wrought alloys, DDRX was the primary dynamic crystallization mechanism. The continuous dynamic recrystallization was an auxiliary nucleation mechanism.

Similar content being viewed by others

References

D.X. Wen, Y.C. Lin, H.B. Li, X.M. Chen, J. Deng, L.T. Li, Mater. Sci. Eng. A 591 (2014) 183–192.

C.J. Wu, Y. Tao, J. Jia, J. Iron Steel Res. Int. 21 (2014) 1152–1157.

W.G. Kim, J.Y. Park, I.M.W. Ekaputra, S.J. Kim, M.H. Kim, Y.W. Kim, Eng. Fail. Anal. 58 (2015) 441–451.

H.Y. Qin, G. Chen, Q. Zhu, C.J. Wang, P. Zhang, J. Iron Steel Res. Int. 22 (2015) 551–556.

Y.C. Lin, X.M. Chen, Mater. Des. 32 (2011) 1733–1759.

L.G. Guo, X.G. Fan, G.F. Yu, H. Yang, Chinese J. Aeronaut. 29 (2016) 30–40.

Z.X. Shi, X.F. Yan, C.H. Duan, J. Alloy. Compd. 652 (2015) 30–38.

Y.B. Tan, Y.H. Ma, F. Zhao, J. Alloy. Compd. 741 (2018) 85–96.

M. Azarbarmas, M. Aghaie-Khafri, J.M. Cabrera, J. Calvo, Mater. Sci. Eng. A 678 (2016) 137–152.

M. Rout, R. Ranjan, S.K. Pal, S.B. Singh, Mater. Sci. Eng. A 711 (2018) 378–388.

C.M. Li, Y.B. Tan, F. Zhao, J. Iron Steel Res. Int. 27 (2020) 1073–1086.

M.J. Wang, C.Y. Sun, M.W. Fu, Z.L. Liu, L.Y. Qian, J. Alloy. Compd. 820 (2020) 153325.

B.C. Xie, B.Y. Zhang, Y.Q. Ning, M.W. Fu, J. Alloy. Compd. 786 (2019) 636–647.

Y.S. Wu, Z. Liu, X.Z. Qin, C.S. Wang, L.Z. Zhou, J. Alloy. Compd. 795 (2019) 370–384.

Z.Q. Yang, Z.D. Liu, X.K. He, S.B. Qiao, C.S. Xie, J. Iron Steel Res. Int. 25 (2018) 1189–1197.

H. Wang, D. Liu, J.G. Wang, H.P. Wang, Y. Hu, H.D. Rao, J. Iron Steel Res. Int. 27 (2020) 807–819.

H. Jiang, J.X. Dong, M.C. Zhang, Z.H. Yao, Metall. Mater. Trans. A 47 (2016) 5071–5087.

H.B. Zhang, K.F. Zhang, H.P. Zhou, Z. Lu, C.H. Zhao, X.L. Yang, Mater. Des. 80 (2015) 51–62.

E.J. Gutiérrez Castañeda, M.G. Hernández Miranda, A. Salinas Rodríguez, J. Aguilar Carrillo, I. Reyes Domínguez, Mater. Lett. 252 (2019) 42–46.

M. Jedrychowski, J. Tarasiuk, B. Bacroix, S. Wronski, J. Appl. Cryst. 46 (2013) 483–492.

D.P. Field, L.T. Bradford, M.M. Nowell, T.M. Lillo, Acta Mater. 55 (2007) 4233–4241.

M.H. Alvi, S.W. Cheong, H. Weiland, A.D. Rollett, Mater. Sci. Forum Trans. Technol Publ. 467–470 (2004) 357–362.

S.K. Pradhan, S. Mandal, C.N. Athreya, K. Arun Babu, B. de Boer, V. Subramanya Sarma, Mater. Sci. Eng. A 700 (2017) 49–58.

X.G. Liu, L.G. Zhang, R.S. Qi, L. Chen, M. Jin, B.F. Guo, J. Iron Steel Res. Int. 23 (2016) 238–243.

S. Mandal, M. Jayalakshmi, A.K. Bhaduri, Metall. Mater. Trans. A 45 (2014) 5645–5656.

S.B. Qiao, Z.D. Liu, X.K. He, C.S. Xie, J. Iron Steel Res. Int. 28 (2021) 46–57.

Z.W. Hsiao, T.Y. Wu, D. Chen, J.C. Kuo, D.Y. Lin, Micron 94 (2017) 15–25.

Y.C. Lin, X.Y. Wu, X.M. Chen, J. Chen, D.X. Wen, J.L. Zhang, L.T. Li, J. Alloy. Comp. 640 (2015) 101–113.

Y. Cao, H.S. Di, J.C. Zhang, T.J. Ma, R.D.K. Misra, Mater. Sci. Eng. A 585 (2013) 71–85.

Acknowledgements

This research was supported by the National Energy Application Technology Research and Engineering Demonstration Program (NY20150101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Q., Jiang, Xl., Chen, Zz. et al. Thermal deformation behavior and microstructure evolution of modified IN617 alloy with different initial states. J. Iron Steel Res. Int. 28, 1315–1328 (2021). https://doi.org/10.1007/s42243-021-00618-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00618-x