Abstract

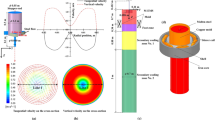

The mathematical model of coupling fluid flow, heat transfer, solidification, solute transport, and the electromagnetic field of the bloom in the upper part of the strand was established with three nozzle types. Then, the flow field, distribution of the temperature, solidification, and macrosegregation of carbon were investigated and compared by numerical modeling. In the case of the straight submerged entry nozzle (SEN), the molten steel flows down deep into the liquid pool, and the depth of the jet flow reaches about 1.0 m beneath the meniscus. The jetting zone is the high-temperature zone. In the case of two-port SEN and four-port SEN, the flow patterns and distribution of temperature in the central longitudinal section are similar. The jet flow impinges directly on the initially solidified shell and then it is divided into two longitudinal circulations. The heat of molten steel is dissipated along with the longitudinal circulations. The negative segregation band was generated near the bloom surface due to the washing effect by the rotating flow at the solidification front with three nozzle types. The negative segregation deteriorates gradually with the number of ports decreasing.

Similar content being viewed by others

References

S. Kholmatov, S. Takagi, L. Jonsson, P. Jönsson, S. Yokoya, ISIJ Int. 47 (2007) 80–87.

Y. Wang, A. Dong, L. Zhang, Steel Res. Int. 82 (2011) 428–439.

H. An, Y. Bao, M. Wang, L. Zhao, Metall. Res. Technol. 115 (2018) 103.

H. Sun, J. Zhang, ISIJ Int. 51 (2011) 1657–1663.

Q. Fang, H. Ni, H. Zhang, B. Wang, Z. Lv, Metals 7 (2017) 146.

H. Sun, J. Zhang, Metall. Mater. Trans. B 45 (2014) 936–946.

S. Wang, G.A. De Toledo, K. Välimaa, S. Louhenkilpi, ISIJ Int. 54 (2014) 2273–2282.

I.C. Ramos, R.D. Morales, S. Garcia-Hernandez, A. Ceballos-Huerta, ISIJ Int. 54 (2014) 1797–1806.

I. Calderón-Ramos, R.D. Morales, M. Salazar-Campoy, Steel Res. Int. 86 (2015) 1610–1621.

I. Calderón-Ramos, R.D. Morales, Metall. Mater. Trans. B 46 (2015) 1314–1325.

M.M. Salazar-Campoy, R.D. Morales, A. Nájera-Bastida, V. Cedillo-Hernández, J.C. Delgado-Pureco, Metall. Mater. Trans. B 48 (2017) 1376–1389.

S. Yokoya, S. Takagi, M. Iguchi, Y. Asako, R. Westoff, S. Hara, ISIJ Int. 38 (1998) 827–833.

S. Yokoya, P.G. Jönsson, K. Sasaki, K. Tada, S. Takagi, M. Iguchi, Scand. J. Metall. 33 (2004) 22–28.

S. Yokoya, S. Takagi, M. Kaneko, M. Iguchi, K. Marukawa, S. Hara, ISIJ Int. 41 (2001) 1215–1220.

S. Yokoya, S. Takagi, K. Tada, M. Iguchi, K. Marukawa, S. Hara, ISIJ Int. 41 (2001) 1201–1207.

M.M. Aboutalebi, F. Lapointe, J. D’amours, M. Isac, R.I.L. Guthrie, Ironmak. Steelmak. 46 (2019) 819–826.

H. Bai, P. Ni, M. Ersson, T. Zhang, P.G. Jönsson, Ironmak. Steelmak. 46 (2019) 911–920.

Y. Wang, W. Chen, D. Jiang, L. Zhang, Steel Res. Int. 91 (2020) 1900470.

H. Chen, M. Long, D. Chen, T. Liu, H. Duan, Int. J. Heat Mass Transfer 126 (2018) 843–853.

Q. Dong, J. Zhang, Y. Yin, B. Wang, Metals 7 (2017) 209.

K.Y.M. Lai, M. Salcudean, S. Tanaka, R.I.L. Guthrie, Metall. Trans. B 17 (1986) 449–459.

Acknowledgements

The authors are grateful for support from the National Natural Science Foundation of China (Grant Nos. U1860206, 51725402, 51874031 and 51904024), the Fundamental Research Funds for the Central Universities (Grant No. FRF-BD-20-04A), the High Steel Center (HSC) at Yanshan University, Beijing International Center of Advanced and Intelligent Manufacturing of High Quality Steel Materials (ICSM), Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM), and the High Quality Steel Consortium (HQSC) at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, Yd., Zhang, Lf., Yang, W. et al. Effect of nozzle type on fluid flow, solidification, and solute transport in mold with mold electromagnetic stirring. J. Iron Steel Res. Int. 29, 237–246 (2022). https://doi.org/10.1007/s42243-021-00577-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00577-3