Abstract

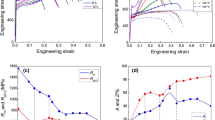

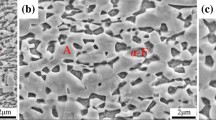

The austenite stability and the mechanical properties in a typical medium Mn grade steel, i.e., 5Mn steel, were investigated under a wide range of strain rates through the combination of experimental and theoretical methodologies. The obtained results indicate that austenite is more stable at a high strain rate, which is due to the suppression of the austenite to martensite transformation. This suppression is attributed to the increased stacking fault energy and the high deformation energy barrier. Moreover, the suppression of martensitic transformation also leads to the decrease in the ultimate tensile strength and the uniform elongation. Owing to the increase in an adiabatic heating temperature, an increase in the uniform elongation is acquired at a high strain rate. The obtained fundamental study results shed light on a wide application of the medium Mn steel under different strain rate conditions.

Similar content being viewed by others

References

B. Hu, H. Luo, F. Yang, H. Dong, J. Mater. Sci. Technol. 33 (2017) 1457–1464.

S. Wang, W.J. Chen, Z.Z. Zhao, X.L. Zhao, X.Y. Luo, Q. Wang, J. Iron Steel Res. Int. (2020). https://doi.org/10.1007/s42243-020-00498-7.

W.Q. Cao, C. Wang, J. Shi, M.Q. Wang, W.J. Hui, H. Dong, Mater. Sci. Eng. A 528 (2011) 6661–6666.

D.W. Suh, S.J. Kim, Scripta Mater. 126 (2017) 63–67.

Y. Chang, C.Y. Wang, K.M. Zhao, H. Dong, J.W. Yan, Mater. Des. 94 (2016) 424–432.

Z. Gronostajski, A. Niechajowicz, R. Kuziak, J. Krawczyk, S. Polak, J. Mater. Process. Technol. 242 (2017) 246–259.

V. Tarigopula, O.S. Hopperstad, M. Langseth, A.H. Clausen, F. Hild, Int. J. Solids Struct. 45 (2007) 601–619.

H. Huh, S.B. Kim, J.H. Song, J.H. Lim, Int. J. Mech. Sci. 50 (2008) 918–931.

S. Xu, D. Ruan, J.H. Beynon, Y. Rong, Mater. Sci. Eng. A 573 (2013) 132–140.

D.Q. Zou, S.H. Li, J. He, Mater. Sci. Eng. A 680 (2016) 54–63.

R. Alturk, L.G. Hector Jr., C.M. Enloe, F. Abu-Farha, T.W. Brown, JOM 70 (2018) 894–905.

R. Rana, E. De Moor, J.G. Speer, D.K. Matlock, JOM 70 (2018) 706–713.

Y.G. Yang, Z.L. Mi, M. Xu, Q. Xiu, J. Li, H.T. Jiang, Mater. Sci. Eng. A 725 (2018) 389–397.

D. De Knijf, C. Föjer, L.A.I. Kestens, R. Petrov, Mater. Sci. Eng. A 638 (2015) 219–227.

R.D.K. Misra, V.S.A. Challa, P.K.C. Venkatsurya, Y.F. Shen, M.C. Somani, L.P. Karjalainen, Acta Mater. 84 (2015) 339–348.

M.M. Wang, C.C. Tasan, D. Ponge, A. Kostka, D. Raabe, Acta Mater. 79 (2014) 268–281.

V.S.A. Challa, R.D.K. Misra, M.C. Somani, Z.D. Wang, Mater. Sci. Eng. A 661 (2016) 51–60.

J. Min, L.G. Hector Jr., L. Zhang, J. Lin, J.E. Carsley, L. Sun, Mater. Sci. Eng. A 673 (2016) 423–429.

B. Sun, F. Fazeli, C. Scott, B. Guo, C. Aranas Jr., X. Chu, M. Jahazi, S. Yue, Mater. Sci. Eng. A 729 (2018) 496–507.

M.H. Zhang, L.F. Li, J. Ding, Q.B. Wu, Y.D. Wang, J. Almer, F.M. Guo, Y. Ren, Acta Mater. 141 (2017) 294–303.

P. Hilkhuijsen, H.J.M. Geijselaers, T.C. Bor, E.S. Perdahcolu, A.H. vd Boogaard, R. Akkerman, Mater. Sci. Eng. A 573 (2013) 100-105.

W.S. Li, H.Y. Gao, H. Nakashima, S. Hata, W.H. Tian, Mater. Sci. Eng. A 649 (2016) 417–425.

J.O. Andersson, T. Helander, L. Höglund, P.F. Shi, B. Sundman, Calphad 26 (2002) 273–312.

Thermodynamic database TCFE9-TCS Steels/Fe-Alloys Database Version 9.0, Thermo-Calc Software AB, Sweden, 2017, https://thermocalc.com/products/databases/steel-and-fe-alloys/. (Accessed 2020–12–13)

N. Chaudhary, A. Abu-Odeh, I. Karaman, R. Arróyave, J. Mater. Sci. 52 (2017) 11048–11076.

T.H. Lee, E. Shin, C.S. Oh, H.Y. Ha, S.J. Kim, Acta Mater. 58 (2010) 3173–3186.

Y.W. Choi, Z.H. Dong, W. Li, S. Schönecker, H. Kim, S.K. Kwon, L. Vitos, Mater. Des. 187 (2020) 108392.

Z.H. Dong, S. Schönecker, D.F. Chen, W. Li, S. Lu, L.Vitos, Int. J. Plasticity 119 (2019) 123–139.

Documentation of Statistics and Machine Learning Toolbox, MathWorks®, 2018, https://se.mathworks.com/help/stats/. (Accessed 2020–12–13)

A. Swami, R. Jain, J. Mach. Learn. Res. 12 (2013) 2825–2830.

S. Allain, O. Bouaziz, J.P. Chateau, Scripta Mater. 62 (2010) 500–503.

H.K. Yang, Z.J. Zhang, Y.Z. Tian, Z.F. Zhang, Mater. Sci. Eng. A 690 (2017) 146–157.

X. Bian, F. Yuan, X. Wu, Mater. Sci. Eng. A 696 (2017) 220–227.

F. Yang, H. Luo, E. Pu, S. Zhang, H. Dong, Int. J. Plasticity 103 (2018) 188–202.

G.B. Olson, M. Cohen, Metall. Trans. A 6 (1975) 791–795.

Y.A. Betanda, A.L. Helbert, F. Brisset, M.H. Mathon, T. Waeckerlé, T. Baudin, Mater. Sci. Eng. A 614 (2014) 193–198.

J.Y. Choi, W. Jin, Scripta Mater. 36 (1997) 99–104.

N.H. van Dijk, A.M. Butt, L. Zhao, J. Sietsma, S.E. Offerman, J.P. Wright, S. van der Zwaag, Acta Mater. 53 (2005) 5439–5447.

N.I. Vázquez-Fernández, T. Nyyssönen, M. Isakov, M. Hokka, V.T. Kuokkala, Acta Mater. 176 (2019) 134–144.

J.T. Benzing, W.A. Poling, D.T. Pierce, J. Bentley, K.O. Findley, D. Raabe, J.E. Wittig, Mater. Sci. Eng. A 711 (2018) 78–92.

T. Masumura, N. Nakada, T. Tsuchiyama, S. Takaki, T. Koyano, K. Adachi, Acta Mater. 84 (2015) 330–338.

G.B. Olson, M. Cohen, Metallurgical transactions A 7 (1976) 1905–1914.

X. Li, S. Schönecker, Acta Mater. 135 (2017) 88–95.

C. Ullrich, S. Martin, C. Schimpf, A. Stark, D. Rafaja, Adv. Eng. Mater. 21 (2019) 1801101.

S. Takaki, K. Fukunaga, J. Syarif, T. Tsuchiyama, Mater. Trans. 45 (2004) 2245–2251.

Acknowledgements

Y.G. Yang, H.T. Jiang, M. Wang, Z.L. Mi, and X.P. Mao gratefully acknowledge the support of the National Key Research and Development Program of China (2017YFB0304404 and 2016YFB0101605), the Program of High-end CNC Machine Tools and Basic Manufacturing Equipment (2019ZX04002030) and China Scholarship Council (CSC). The authors would like to thank N. Chaudhary and co-authors for sharing the SFE database used in their publication. Y.G. Yang and W.Z. Mu would like to thank the Swedish iron and steel research office (Jernkontoret), in particular Hugo Carlssons Stiftelse and Gerhard von Hofstens Stiftelse to support Y.G. Yang’s research activity in KTH. W.Z. Mu would like to acknowledge Associate Professor H.H. Mao (KTH) for the discussion of the thermodynamics, and he also wants to thank Swedish Foundation for International Cooperation in Research and Higher Education (STINT, No. PT2017-7330 & IB2020-8781) for the financial support. X.Q. Li would like to acknowledge the Swedish Research Council.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yang, Yg., Mu, Wz., Li, Xq. et al. Effects of strain rate on austenite stability and mechanical properties in a 5Mn steel. J. Iron Steel Res. Int. 29, 316–326 (2022). https://doi.org/10.1007/s42243-021-00569-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00569-3