Abstract

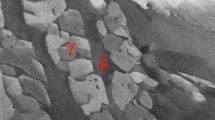

In order to understand the high-temperature deformation behaviour of alloy having hard surface layer, thermo-mechanically treated duplex stainless steel (DSS) is boronised for 0.75–6 h at 1223 K and subsequently deformed under compression mode at the same temperature under strain rate condition of 1 × 10−3, 2 × 10−4 and 6 × 10−5 s−1 until strain of 0.4. The substrate microstructure is almost isotropic with grain size after boronising with layer thickness between 1.61 and 2.74 μm. X-ray diffraction results confirm the formation of boride on DSS surface. The surface hardness of DSS increases from 387 to 1000–2400 HV after boronising. Uniform boronised layer with thickness of 20–40 μm is formed at DSS surface. Compression results show that the flow stress of the deformation increases with the strain rate and boronising time. For the boronised samples, the flow stress range is between 5 and 89 MPa. To determine the actual effect of the boronised layer on the flow stress, the results are also compared with those from un-boronised samples having similar microstructure. The results suggest that at a constant grain size, even with the hardest layer, the effect of hard surface layer on the flow stress almost could be negligible when the deformation rate is slow, but at faster deformation rate, even in the layer with the least hardness, the flow stress shows a significant increase. It is also observed that the hard boride surface disintegration could be avoided at a sufficiently low deformation flow stress that could be attributed to superplasticity.

Similar content being viewed by others

References

F. Kustas, B. Mishra, J. Zhou, Surf. Coat. Technol. 153 (2002) 25–30.

X. Nie, E.I. Meletis, J.C. Jiang, A. Leyland, A.L. Yerokhin, A. Matthews, Surf. Coat. Technol. 149 (2002) 245–251.

D.A. Stewart, P.H. Shipway, D.G. McCartney, Wear 225–229 (1999) 789–798.

Y. Wang, S. Jiang, M. Wang, S. Wang, T.D. Xiao, P.R. Strutt, Wear 237 (2000) 176–185.

L. Benea, P.L. Bonora, A. Borello, S. Martelli, Wear 249 (2001) 995–1003.

S. Wilson, A.T. Alpas, Surf. Coat. Technol. 108–109 (1998) 369–376.

J.R. Davis, Surface hardening of steels: understanding the basics, ASM International, Material Park, OH, USA, 2002.

H. Holleck, V. Schier, Surf. Coat. Technol. 76–77 (1995) 328–336.

Y. Sahin, G. Sur, Surf. Coat. Technol. 179 (2004) 349–355.

B.S. Suh, W.J. Lee, Thin Solid Films 295 (1997) 185–192.

G. Pantazopoulos, T. Papazoglou, P. Psyllaki, G. Sfantos, S. Antoniou, K. Papadimitriou, J. Sideris, Surf. Coat. Technol. 187 (2004) 77–85.

K.H. Habig, Mater. Des. 2 (1980) 83–92.

S.H. Choo, S. Lee, S.J. Kwon, Metall. Mater. Trans. A 30 (1999) 1211–1221.

J. Lee, J. Jang, B. Joo, Y. Son, Y. Moon, Trans. Nonferrous Met. Soc. China 19 (2009) 917–920.

Y. Chang, D. Wang, Surf. Coat. Technol. 200 (2005) 2187–2191.

J.D. Hunn, E.H. Lee, T.S. Byun, L.K. Mansur, J. Nucl. Mater. 282 (2000) 131–136.

W. Möller, S. Parascandola, T. Telbizova, R. Günzel, E. Richter, Surf. Coat. Technol. 136 (2001) 73–79.

D. Neves, A.E. Diniz, M.S.F. Lima, Appl. Surf. Sci. 282 (2013) 680–688.

B. Lux, R. Haubner, in: A.H. Lettington, J.W. Steeds (Eds.), Diamond as a Wear-Resistant Coating, Thin Film Diamond, Springer, Dordrecht, 1993, pp. 127–141.

J. Rus, C.L. De Leal, D.N. Tsipas, J. Mater. Sci. Lett. 4 (1985) 558–560.

I. Campos-Silva, M. Ortiz-Domínguez, O. Bravo-Bárcenas, M.A. Doñu-Ruiz, D. Bravo-Bárcenas, C. Tapia-Quintero, M.Y. Jiménez-Reyes, Surf. Coat. Technol. 205 (2010) 403–412.

B.J. Smith, R. Overholster, S. Aust, Boronised medical implants and process of manufacture, USA, US20060074491A1, 2004.

J. Gossett, Boronized valve seal, German, EP1834121A1, 2006.

S.R. Scales, Method of finishing a steel article having a boronized and carburized case, USA, US4012238, 1977.

E.M. Fainshmidt, V.F. Pegashkin, Met. Sci. Heat Treat. 42 (2000) 263–266.

J. Jiang, Y. Wang, Q. Zhong, Q. Zhou, L. Zhang, Surf. Coat. Technol. 206 (2011) 473–478.

E.E. Vera Cárdenas, R. Lewis, A.I. Martínez Pérez, J.L. Bernal Ponce, F.J. Pérez Pinal, M.O. Domínguez, E.D. Rivera Arreola, Adv. Mech. Eng. 8 (2016) 168781401663025.

R. Narayan, Diamond-based materials for biomedical applications, Woodhead Publising Limited, Elsevier, Cambridge, UK, 2013.

I. Campos-Silva, M. Ortiz-Domínguez, M. Keddam, N. López-Perrusquia, A. Carmona-Vargas, M. Elías-Espinosa, Appl. Surf. Sci. 255 (2009) 9290–9295.

E. Evangelista, H.J. McQueen, M. Niewczas, M. Cabibbo, Can. Metall. Quart. 43 (2004) 339–353.

Leif, Weld. World 56 (2012) 65–76.

L. Weber, P.J. Uggowitzer, Mater. Sci. Eng. A 242 (1998) 222–229.

E. Wallis, Mater. Corros. 41 (1990) 155–162.

P. Cunat, Alloying elements in stainless steel and other chromium-containing alloys, ICDA, Paris, France, 2004.

D.N. Zou, Y. Han, W. Zhang, G.W. Fan, J. Iron Steel Res. Int. 17 (2010) No. 11, 67–72.

S. Spigarelli, M. El Mehtedi, M. Cabibbo, E. Evangelista, J. Kaneko, A. Jäger, V. Gartnerova, Mater. Sci. Eng. A 462 (2007) 197–201.

I. Jauhari, H.A.M. Yusof, R. Saidan, Mater. Sci. Eng. A 528 (2011) 8106–8110.

I. Jauhari, S. Harun, S.A. Jamlus, M.F.M. Sabri, Metall. Mater. Trans. A 48 (2017) 975–981.

R. Hasan, I. Jauhari, H. Ogiyama, R.D. Ramdan, Key Eng. Mater. 326–328 (2006) 1745–1748.

N.H. Abd Aziz, I. Jauhari, H.A.M. Yusof, N.W. Ahamad, Defect Diffus. Forum 283–286 (2009) 458–463.

H. Li, G. Fan, Y. He, J. Bai, C. Zhang, P. Han, Steel Res. Int. 86 (2015) 84–88.

C. Kapfenberger, B. Albert, R. Pöttgen, H. Huppertz, Zeitschrift für Kristallographie—Crystalline Materials 221 (2006) 477–481.

L. Han, S. Wang, J. Zhu, S. Han, W. Li, B. Chen, X. Wang, X. Yu, B. Liu, R. Zhang, Y.W. Long, J.G. Cheng, J. Zhang, Y. Zhao, C. Jin, Appl. Phys. Lett. 106 (2015) 221902.

H. Okamoto, J. Phase Equilib. Diff. 25 (2004) 297–298.

V. Dybkov, J. Miner. Met. Mater. Eng. 2 (2016) 30–46.

M.M.E Ali, J. Chen, I. Harran, B. Sun, X. Cai, H. Wang, L. Tao, Y. Chen, J. Phys. Chem. Solids 127 (2018) 238–244.

A. Gueddouh, B. Bentria, I.K. Lefkaier, J. Magn. Magn. Mater. 406 (2016) 192–199.

S.V. Astafurov, G.G. Maier, E.V. Melnikov, V.A. Moskvina, M.Y. Panchenko, E.G. Astafurova, Mater. Sci. Eng. A 756 (2019) 365–372.

R. Hasan, I. Jauhari, H. Ogiyama, R.D. Ramdan, Key Eng. Mater. 326–328 (2006) 1233–1236.

I. Jauhari, H.A.M. Yusof, S. Rozali, H. Ogiyama, J. Solid Mech. Mater. Eng. 1 (2007) 539–546.

N.M. Sultan, I. Jauhari, M.F.M. Sabri, Mater. Res. Express 6 (2019) 1165f7.

K.A. Padmanabhan, R. Vasin, F. Enikeev, Superplastic flow: phenomenology and mechanics, Springer-Verlag Berlin Heidelberg, New York, USA, 2012.

A. Marchattiwar, A. Sarkar, J.K. Chakravartty, B.P. Kashyap, J. Mater. Eng. Perform. 22 (2013) 2168–2175.

A.V. Mikhaylovskaya, A.O. Mosleh, A.D. Kotov, J.S. Kwame, T. Pourcelot, I.S. Golovin, V.K. Portnoy, Mater. Sci. Eng. A 708 (2017) 469–477.

F. Tehovnik, B. Zuzek, J. Burja, Mater. Technol. 50 (2016) 989–993.

Y. Maehara, Y. Ohmori, Metall. Mater. Trans. A 18 (1987) 663–672.

M. Ma, H. Ding, Z.Y. Tang, J.W. Zhao, Z.H. Jiang, G.W. Fan, J. Iron Steel Res. Int. 23 (2016) 244–252.

R.R. Balokhonov, V.A. Romanova, Phys. Mesomech. 13 (2010) 28–37.

F. Ren, F. Chen, J. Chen, X. Tang, J. Manuf. Process 31 (2018) 640–649.

F. Peng, X. Dong, K. Liu, H. Xie, J. Iron Steel Res. Int. 22 (2015) 931–936.

B.K. Choudhary, Metall. Mater. Trans. A 45 (2014) 302–316.

A.H. Chokshi, Mater. Chem. Phys. 210 (2017) 152–161.

X. Li, X. Lü, H. Wu, B. Ji, J. Chen, J. Li, Procedia Eng. 207 (2017) 1880–1885.

J. Wang, Y. Liu, B. Liu, Y. Wang, Y. Cao, T. Li, R. Zhou, Mater. Sci. Eng. A 689 (2017) 233–242.

C. Cui, Y. Gao, S. Wei, G. Zhang, Y. Zhou, X. Zhu, J. Alloy. Compd. 716 (2017) 321–329.

N. Hirota, F. Yin, T. Azuma, T. Inoue, Sci. Technol. Adv. Mater. 11 (2010) 025004.

H.B. Li, Z.H. Jiang, Z.R. Zhang, Y. Yang, J. Iron Steel Res. Int. 16 (2009) No. 1, 58–61.

V.I. Dybkov, W. Lengauer, K. Barmak, J. Alloy. Compd. 398 (2005) 113–122.

J. Zuno-Silva, M. Keddam, M. Ortiz-Domínguez, M. Carlos Elias-Espinosac, F. Cervantes-Sodi, J. Oseguera-Peña, L.D.F. De-Dios, O.A. Gomez-Vargas, Mater. Res. 21 (2018) e20180173.

C.H. Xu, J.K. Xi, W. Gao, J. Mater. Process. Technol. 65 (1997) 94–98.

N. Haghdadi, P. Cizek, H. Beladi, P.D. Hodgson, Acta Mater. 126 (2017) 44–57.

Acknowledgements

This research work was financed by Postgraduate Research Grant (PPP) (Project No. PG019-2014B) from University of Malaya, Malaysia and Akaun Amanah Industri Bekalan Elektrik (Project No. GA012-2019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sultan, N.M., Jauhari, I., Saidan, R. et al. High-temperature deformation behaviour of duplex stainless steel with hard boronised layer. J. Iron Steel Res. Int. 28, 244–253 (2021). https://doi.org/10.1007/s42243-020-00544-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00544-4