Abstract

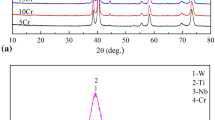

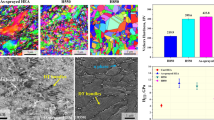

High-/medium-entropy stainless alloys (HESAs/MESAs) are a new kind of alloys with great potential to combine excellent properties from high-/medium-entropy alloys (HEAs/MEAs) and stainless steels. A CrFeNi MESA was chosen to investigate its microstructures and mechanical behaviors. After homogenization, the strength and ductility of CrFeNi MESAs with single-phase face-centered-cubic (fcc) structure were higher compared with those of Fe100−x–yCrxNiy austenitic stainless steels. Cr-rich body-centered-cubic (bcc) precipitates and heterogeneous structure were introduced by cold rolling and annealing at 800 °C. Rolling at 700 °C results in higher dislocation density and the occurrence of lamellar Cr-rich bcc precipitates. High-density dislocations and fcc grains with heterogeneous structure, together with Cr-rich bcc precipitates, contribute to a yield strength improvement of about 50 MPa, and appreciable tensile yield strength of ~ 540 MPa and fracture strain of ~ 20% are obtained. It reveals that not only compositional variations but also grain size and phase structure tuning can be utilized for achieving desired mechanical properties.

Similar content being viewed by others

References

Q. Liu, H. Sun, H. Yin, L. Guo, J. Qiu, J. Lin, Z. Tang, Corros. Sci. 160 (2019) 108174.

A.A. Tiamiyu, U. Eduok, J.A. Szpunar, A.G. Odeshi, Sci. Rep. 9 (2019) 12116.

Z. Ren, A.H. Heuer, F. Ernst, Acta Mater. 167 (2019) 231–240.

L. Xiong, Z.S. You, S.D. Qu, L. Lu, Acta Mater. 150 (2018) 130–138.

J.E. Pawel, D.J. Alexander, M.L. Grossbeck, A.W. Longest, A.F. Rowcliffe, G.E. Lucas, S. Jitsukawa, A. Hishinuma, K. Shiba, J. Nucl. Mater. 212–215 (1994) 442–447.

R.P. Reed, Acta Metall. 10 (1962) 865–877.

E. Salama, M.M. Eissa, A.S. Tageldin, Nucl. Eng. Technol. 51 (2019) 784–791.

M. Murayama, K. Hono, H. Hirukawa, T. Ohmura, S. Matsuoka, Scripta Mater. 41 (1999) 467–473.

J.C.M. Farrer, The alloy tree: a guide to low-alloy steels, stainless steels, and nickel-base alloys, CRC, Boca Raton, USA, 2004.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61 (2014) 1–93.

S.S. Sohn, A. Kwiatkowski da Silva, Y. Ikeda, F. Körmann, W. Lu, W.S. Choi, B. Gault, D. Ponge, J. Neugebauer, D. Raabe, Adv. Mater. 319 (2019) 1807142.

Y.P. Lu, Y. Dong, S. Guo, L. Jiang, H.J. Kang, T.M. Wang, B. Wen, Z.J. Wang, J.C. Jie, Z.Q. Cao, H.H. Ruan, T.J. Li, Sci. Rep. 4 (2014) 6200.

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, P.K. Liaw, Acta Mater. 60 (2012) 5723–5734.

C.P. Lee, Y.Y. Chen, C.Y. Hsu, J.W. Yeh, H.C. Shih, J. Electrochem. Soc. 154 (2007) C424–C430.

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, D.B. Miracle, J. Mater. Sci. 47 (2012) 6522–6534.

D. Raabe, C.C. Tasan, H. Springer, M. Bausch, Steel Res. Int. 86 (2015) 1127–1138.

V. Raghavan, J. Phase Equilib. 24 (2003) 261–264.

D. Liang, C. Zhao, W. Zhu, P. Wei, F. Jiang, Y. Zhang, Q. Sun, F. Ren, Mater. Sci. Eng. A 762 (2019) 138107.

Q. Li, T.W. Zhang, J.W. Qiao, S.G. Ma, D. Zhao, P. Lu, B. Xu, Z.H. Wang, Mater. Sci. Eng. A 767 (2019) 138424.

K. Chen, Y. Yang, G. Shao, K.J. Liu, Steel Res. Int. 82 (2011) 1325–1331.

X.L. Liu, Q.Q. Xue, W. Wang, L.L. Zhou, P. Jiang, H.S. Ma, F.P. Yuan, Y.G. Wei, X.L. Wu, Materialia 7 (2019) 100376.

C. Laird, H.I. Aaronson, Acta Metall. 17 (1969) 505–519.

D.A. Porter, K.E. Easterling, Phase transformation in metals and alloys, 2nd ed., Chapman and Hall, New York, USA, 1992.

G. Laplanche, S. Berglund, C. Reinhart, A. Kostka, F. Fox, E.P.J.A.M. George, Acta Mater. 161 (2018) 338–351.

M. Grujicic, W.S. Owen, Acta Metall. Mater. 43 (1995) 4201–4211.

K.Y. Tsai, M.H. Tsai, J.W. Yeh, Acta Mater. 61 (2013) 4887–4897.

G. Neumann, C. Tuijn, Self diffusion and impurity diffusion in pure metals: handbook of experimental data, Elsevier, Oxford, UK, 2009.

J.L. Maloney, W.M. Garrison Jr., Acta Mater. 53 (2005) 533–551.

L.E. Iorio, W.M. Garrison Jr., Metall. Mater. Trans. A 37 (2006) 1165–1173.

J. Hou, X. Shi, J. Qiao, Y. Zhang, P.K. Liaw, Y. Wu, Mater. Des. 180 (2019) 107910.

T.W. Zhang, S.G. Ma, D. Zhao, Y.C. Wu, Y. Zhang, Z.H. Wang, J.W. Qiao, Int. J. Plasticity 124 (2019) 226–246.

H.Y. Yasuda, H. Miyamoto, K. Cho, T. Nagase, Mater. Lett. 199 (2017) 120–123.

B. Gwalani, V. Soni, M. Lee, S.A. Mantri, Y. Ren, R. Banerjee, Mater. Des. 121 (2017) 254–260.

B.B. He, B. Hu, H.W. Yen, G.J. Cheng, Z.K. Wang, H.W. Luo, M.X. Huang, Science 357 (2017) 1029–1032.

P. Behjati, A. Kermanpur, A. Najafizadeh, H.S. Baghbadorani, Mater. Sci. Eng. A 618 (2014) 16–21.

J. Gu, M. Song, Scripta Mater. 162 (2019) 345–349.

S.R. Reddy, U. Sunkari, A. Lozinko, R. Saha, S. Guo, P.P. Bhattacharjee, Intermetallics 114 (2019) 106601.

S.R. Reddy, S. Yoshida, T. Bhattacharjee, N. Sake, A. Lozinko, S. Guo, P.P. Bhattacharjee, N. Tsuji, Sci. Rep. 9 (2019) 11505.

E. Nembach, Particle strengthening of metals and alloys, Wiley, New York, USA, 1997.

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, Z.P. Lu, Acta Mater. 102 (2016) 187–196.

K. Ming, X. Bi, J. Wang, Int. J. Plasticity 100 (2017) 177–191.

T. Gladman, Mater. Sci. Technol. 15 (1999) 30–36.

S. Yoshida, T. Bhattacharjee, Y. Bai, N. Tsuji, Scripta Mater. 134 (2017) 33–36.

S.W. Wu, G. Wang, Q. Wang, Y.D. Jia, J. Yi, Q.J. Zhai, J.B. Liu, B.A. Sun, H.J. Chu, J. Shen, P.K. Liaw, C.T. Liu, T.Y. Zhang, Acta Mater. 165 (2019) 444–458.

T.C. Courtney, Mechanical behavior of materials, McGraw-Hill, New York, USA, 2004.

Z. Wu, H. Bei, G.M. Pharr, E.P. George, Acta Mater. 81 (2014) 428–441.

D.B. Miracle, O.N. Senkov, Acta Mater. 122 (2017) 448–511.

M. Laurent-Brocq, L. Perrière, R. Pirès, G. Bracq, T. Rieger, Y. Danard, I. Guillot, Materialia 7 (2019) 100404.

M. Komarasamy, S. Shukla, N. Ley, K. Liu, K. Cho, B. McWilliams, R. Brennan, M.L. Young, R.S. Mishra, Mater. Sci. Eng. A 736 (2018) 383–391.

Acknowledgements

The authors would like to acknowledge the financial support of the Natural Science Foundation of Shanxi Province, China (Nos. 201901D111105 and 201901D111114), Transformation of Scientific and Technological Achievements Programs of Higher Education Institutions in Shanxi (2019), and the opening project of State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology, No. KFJJ20-13 M).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, K., Wang, Xj., Zhang, Tw. et al. Tuning Cr-rich nanoprecipitation and heterogeneous structure in equiatomic CrFeNi medium-entropy stainless alloys. J. Iron Steel Res. Int. 29, 529–536 (2022). https://doi.org/10.1007/s42243-020-00520-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00520-y