Abstract

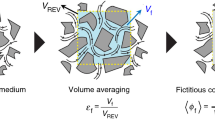

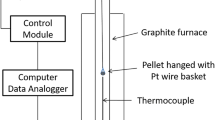

A mathematical model based on the computational fluid dynamics method, heat and mass transfer in porous media and the unreacted shrinking core model for the oxidation reaction of an individual magnetite pellet during preheating was established. The commercial software COMSOL Multiphysics was used to simulate the change in the oxidation degree of the pellet at different temperatures and oxygen concentrations, and the simulated results were compared with the experimental results. The model considered the influence of the exothermic heat of the reaction, and the enthalpy change was added to calculate the heat released by the oxidation. The results show that the oxidation rate on the surface of the pellet is much faster than that of the inside of the pellet. Temperature and oxygen concentration have great influence on the pellet oxidation model. Meanwhile, the exothermic calculation results show that there is a non-isothermal phenomenon inside the pellet, which leads to an increase in temperature inside the single pellet. Under the preheating condition of 873–1273 K (20% oxygen content), the heat released by the pellet oxidation reaction in a chain grate is 7.8 × 106–10.8 × 106 kJ/h, which is very large and needs to be considered in the magnetite pellet oxidation modelling.

Similar content being viewed by others

References

M. Barati, Int. J. Miner. Process. 89 (2008) 30–39

F. Zhang, D.Q. Zhu, J. Pan, Z.Q. Guo, M.J. Xu, J. Iron Steel Res. Int. 27 (2020) 770–781.

F.Q. Gu, Y.B. Zhang, G.H. Li, Q. Zhong, J. Luo, Z.J. Su, M.J. Rao, Z.W. Peng, T. Jiang, J. Iron Steel Res. Int. (2020). https://doi.org/10.1007/s42243-020-00376-2.

C.Y.C. Jonsson, J. Stjernberg, H. Wiinikka, B. Lindblom, D. Boström, M. Öhman, Energy Fuels 27 (2013) 6159–6170.

S.P.E. Forsmo, S.E. Forsmo, P.O. Samskog, B.M.T. Björkman, Powder Technol. 183 (2008) 247–259.

J.A. Thurlby, Metall. Trans. B 19 (1988) 103–112.

G.H. Han, T. Jiang, Y.B. Zhang, Y.F. Huang, G.H. Li, J. Iron Steel Res. Int. 18 (2011) No. 8, 14–19.

M. Kazemi, M.S. Pour, D. Sichen, Metall. Mater. Trans. B 48 (2017) 1114–1122.

L.X. Yang, E. Matthews, ISIJ Int. 37 (1997) 854–861.

R.A. Davis, D.J. Englund, Can. J. Chem. Eng. 81 (2003) 86–93.

J. Szekely, J.W. Evans, Chem. Eng. Sci. 25 (1970) 1091–1107.

J. Szekely, J.W. Evans, Metall. Trans. 2 (1971) 1691–1698.

R. Beheshti, J. Moosberg-Bustnes, R.E. Aune, in: The Minerals, Metals & Materials Society (Eds.), TMS 2014: 143rd Annual Meeting & Exhibition, Springer International Publishing, Cham, Switzerland, 2016, pp. 495–502.

T. Melchiori, P. Canu, Ind. Eng. Chem. Res. 53 (2014) 8980–8995.

J. Szekely, J.W. Evans, Chem Eng Sci. 26 (1971) 1901–1913.

H. Ahn, S. Choi, Comput. Chem. Eng. 97 (2017) 13–26.

P.C. Pistorius, M. Tang, in: T.P. Battle, J.P. Downey, L.D. May, B. Davis, N.R. Neelameggham, S. Sanchez-Segado, P.C. Pistorius (Eds.), Drying, Roasting, and Calcining of Minerals, Springer International Publishing, Cham, Switzerland, 2016, pp. 203–208.

S.M.M. Nouri, H. Ale Ebrahim, E. Jamshidi, Chem. Eng. J. 166 (2011) 704–709.

M.S. Valipour, M.Y.M. Hashemi,Y. Saboohi, Adv. Powder Technol. 17 (2006) 277–295.

D. Papanastassiou, G. Bitsianes, Metall. Trans. 4 (1973) 487–496.

H.J. Cho, M. Tang, P.C. Pistorius, Metall. Mater. Trans. B 45 (2014) 1213–1220.

R.Q. Liang, S. Yang, F.S. Yan, J.C. He, J. Iron Steel Res. Int. 20 (2013) No. 9, 16–20.

X. Chen, J. Dai, Z. Luo, Particuology 11 (2013) 703–714.

X.B. Chen, P. Yu, S.H. Winoto, H.T. Low, Int. J. Numer. Method. H. 19 (2009) 223–241.

A. Amiri, K. Vafai, Int. J. Heat Mass Transfer 41 (1998) 4259–4279.

J.B.Y. Bachmat, Theory and applications of transport in porous media, Springer, 1990.

Y. Zhang, J. Feng, J. Xu, Y. Zhang, J. Yang, Energy Convers. Manage. 52 (2011) 2064–2071.

D. Papanastassiou, G. Bitsianes, Metall. Trans. 4 (1973) 477–486.

H.Q. Zhang, J.T. Fu, J. Pan, F. Zhang, Z.Q. Guo, J. Wuhan Univ. Technol. 33 (2018) 1516–1523.

M. Tang, H.J. Cho, P.C. Pistorius, Metall. Mater. Trans. B 45 (2014) 1304–1314.

H.Q. Zhang, J.T. Fu, Int. J. Miner. Metall. Mater. 24 (2017) 603–610.

D. Zhu, C. Yang, J. Pan, X. Li, Metall. Mater. Trans. B 47 (2016) 2919–2930.

Y.P. Song, W. Dong, X.Q. Peng, J.Z. Zhang, S.J. Pan, Metal Materials and Metallurgy Engineering 40 (2012) No. 4, 10–14.

R.S. Wang, Sintering and Pelletizing (1994) No. 6, 48–52.

Acknowledgements

The authors would like to acknowledge the support of the National Natural Science Foundation of China (51675245).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pu, Z., Zhou, F., Sun, Y. et al. Modelling and numerical simulation of isothermal oxidation of an individual magnetite pellet based on computational fluid dynamics. J. Iron Steel Res. Int. 28, 799–808 (2021). https://doi.org/10.1007/s42243-020-00485-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00485-y