Abstract

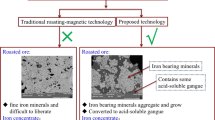

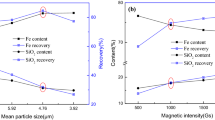

A novel technology, modified roasting in CO–CO2 mixed gas and magnetic separation, was presented to recover iron from copper slag. The effects of various parameters such as dosage of flux (CaO), gas flowrate of CO and CO2, roasting temperature, roasting time, particle size of modified slag and magnetic flux density on the oxidized modification and magnetic separation were investigated by comparison of the X-ray diffraction patterns and iron recovery ratio. The optimum conditions for recovering iron by oxidizing roasting and magnetic separation are as follows: calcium oxide content of 25 wt.%, mixed gas flow rates of CO2 and CO of 180 and 20 mL/min, oxidizing roasting at 1323 K for 2 h, grinding the modified slag to 38.5–25.0 μm and magnetic separation at 170 mT. The mineralogical and microstructural characteristics of modified slag revealed that the iron-bearing minerals in the copper slag were oxidized, the generated magnetite grew into large particles, and the silicate in copper slag was combined with calcium oxide to form calcium silicate. Finally, the iron-bearing concentrate with an iron grade of 54.79% and iron recovery ratio of 80.14% was effectively obtained.

Similar content being viewed by others

References

C.J. Shi, C. Meyer, A. Behnood, Resour. Conserv. Recycl. 52 (2008) 1115–1120.

B. Gorai, R.K. Jana, Resour. Conserv. Recycl. 39 (2003) 299–313.

H.T. Shen, E. Forssberg, Waste Manag. 23 (2003) 933–949.

P.K. Gbor, V. Mokri, C.Q. Jia, J. Environ. Sci. Health Part A 35 (2000) 147–167.

M. Najimi, A.R. Pourkhorshidi, Mag. Concr. Res. 63 (2011) 605–615.

H.Y. Cao, N.X. Fu, C.G. Wang, L. Zhang, F.S. Xia, Z.T. Sui, N.X. Feng, Multipurp. Util. Min. Resour. (2009) No. 2, 8–10.

U. Brinkmann, W. Laqua, Phys. Chem. Miner. 12 (1985) 283–290.

J.L. Zeng, K.M. Xiao, Nonferrous Met. Sci. Eng. 2 (2011) No. 6, 71–73.

T.J. Veasey, J. Process Mech. Eng. 211 (1997) 61–64.

Z. Cao, T. Sun, X. Xue, Z. Liu, Minerals 6 (2016) 119.

B.S. Kim, S.K. Jo, D. Shin, J.C. Lee, S.B. Jeong, Int. J. Miner. Process. 124 (2013) 124–127.

R.M. Jiao, X. Peng, C.Y. Wang, B.Z. Ma, Y.Q. Chen, Int. J. Miner. Metall. Mater. 24 (2017) 974–982.

Y.B. Ma, X.Y. Du, Y.Y. Shen, G.Z. Li, M. Li, Metals 7 (2017) 321.

Y. Fan, E. Shibata, A. Iizuka, T. Nakamura, Mater. Trans. 55 (2014) 958–963.

Y. Fan, E. Shibata, A. Iizuka, T. Nakamura, Metall. Mater. Trans. B 46 (2015) 2158–2164.

Y. Fan, E. Shibata, A. Iizuka, T. Nakamura, Metall. Mater. Trans. B 47 (2016) 2754–2760.

Z.Q. Guo, D.Q. Zhu, P. Jian, T.J. Wu, F. Zhang, Metals 6 (2016) 86.

Z.Q. Guo, D.Q. Zhu, P. Jian, F. Zhang, JOM 68 (2016) 2341–2348.

X.J. Hu, T. Zhang, H.Y. Yan, H. Matsuura, F. Tsukihashi, K.C. Chou, ISIJ Int. 52 (2012) 1529–1534.

J.H. Heo, B.S. Kim, J.H. Park, Metall. Mater. Trans. B 44 (2013) 1352–1363.

J.H. Hu, H. Wang, L.M. Zhao, L. Li, H.L. Liu, J. Saf. Environ. 11 (2011) No. 2, 90–93.

D. Durinck, F. Engström, S. Arnout, J. Heulens, P.T. Jones, B. Björkman, B. Blanpain, P. Wollants, Resour. Conserv. Recycl. 52 (2008) 1121–1131.

Z.Q. Guo, D.Q. Zhu, J. Pan, F. Zhang, J. Clean. Prod. 187 (2018) 910–922.

J.R. Garcia, M. Suarez, C.G. Guarido, J. Rodriguez, Anal. Chem. 56 (1984) 193–196.

E.T. Turkdogan, J.V. Vinters, Metall. Trans. 3 (1972) 1561–1574.

Y. Sasaki, S. Hara, D.R. Gaskell, G.R. Belton, Metall. Trans. B 15 (1984) 563–571.

Y. Li, J.A. Lucas, G.M. Evans, I.P. Ratchey, G.R. Belton, Metall. Mater. Trans. B 31 (2000) 1049–1057.

H.R. Fernandes, A. Gaddam, D.U. Tulyaganov, J.M.F. Ferreira, J. Non-Cryst. Solids 406 (2014) 54–61.

Z.H. Yang, Z.H. Ma, Steel Res. Int. 88 (2017) 1600145.

Acknowledgements

The authors wish to express thanks to National Natural Science Foundation of China (Grant No. 51774154) and the Jiangxi Natural Science Foundation (Grant No. 20151BAB206029) for the financial support for this research. And we also thank the Testing Center of Jiangxi University of Science and Technology for testing of samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Pg., Liu, Js., Xiao, Yy. et al. Recovery of iron from copper slag via modified roasting in CO–CO2 mixed gas and magnetic separation. J. Iron Steel Res. Int. 27, 796–806 (2020). https://doi.org/10.1007/s42243-020-00413-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00413-0