Abstract

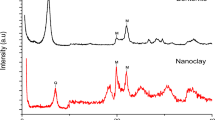

A new process for manufacturing organically compounded bentonite was developed successfully based on the organic intercalation and layered structure of bentonite. The main steps in the proposed process included wet sodium activation of bentonite ore, organic compounding and high-pressure roll grinding. The optimum procedure is recommended as follows: 5 mass% of sodium carbonate powder and 30 wt.% water are added to activate the bentonite ore for 24 h to prepare activated bentonite; 0.5 wt.% of organic molecules are added into the activated bentonite for organic compounding for 12 h; then, the high-pressure roll grinding is followed to treat the organically compounded bentonite; and finally, drying and fine grinding are performed for preparing the final organically compounded bentonite product with 10 wt.% moisture and 98% passing 0.074 mm. The obtained organically compounded bentonite was characterized using an X-ray diffractometer, a scanning electron microscope and an X-ray photoelectron spectrometer. To confirm the effect of organically compounded bentonite on green balls, the pelletizing tests were carried out. The results showed that high-pressure roll grinding can not only enhance the ability of the crystal layer to hold the combined water, but also strengthen the intercalation compounding of the organic additive, which is beneficial for the formation of a fiber-interlaced structure of the organically compounded bentonite and improves the quality index of the bentonite itself. Also, the organically compounded bentonite is helpful to improve the indexes of green balls.

Similar content being viewed by others

References

S.K. Kawatra, S.J. Ripke, Int. J. Miner. Process. 72 (2003) 429–441.

Y.L. Zhou, S.K. Kawatra, Miner. Process. Extr. Metall. Rev. 38 (2017) 83–91.

J.A. Halt, S.K. Kawatra, Miner. Process. Extr. Metall. Rev. 38 (2017) 73–82.

U. Srivastava, S.K. Kawatra, T.C. Eisele, Metall. Mater. Trans. B 44 (2013) 1000–1009.

Y.L. Zhou, Y.B. Zhang, P. Li, G.H. Li, T. Jiang, Powder Technol. 251 (2014) 1–8.

Y.B. Zhang, M.M. Lu, Z.J. Su, J. Wang, Y.K. Tu, X.J. Chen, C.T. Cao, F.Q. Gu, S. Liu, T. Jiang, Appl. Clay Sci. 180 (2019) 105177.

R.L. Virta, 2010 Mineral Commodity Summaries: Clays. USA: US Geological Survey. (2010) 45.

S.K. Kawatra, S.J. Ripke, Int. J. Miner. Process. 65 (2002) 141–149.

J.A. Halt, S.K. Kawatra, Min. Metall. Explor. 31 (2014) 73–94.

H.Q. Ji, G.Z. Wu, M.C. Zi, D.Y. Chen, Energy Fuels 30 (2016) 7206–7213.

M.C. Karakaya, N. Karakaya, S. Bakir, Appl. Clay Sci. 54 (2011) 159–165.

N. Yener, C. Biçer, M. Önal, Y. Sarıkaya, Appl. Surf. Sci. 258 (2012) 2534–2539.

C. Wang, X. Jiang, L. Zhou, G. Xia, Z. Chen, M. Duan, X. Jiang, Chem. Eng. J. 219 (2013) 469–477.

X.W. Liu, R.L. Zhu, J.F. Ma, F. Ge, Y. Xu, Y. Liu, Colloids Surf. A 434 (2013) 200–206.

S.L. Bartelt-Hunt, S.E. Burns, J.A. Smith, J. Colloid Interface Sci. 266 (2003) 251–258.

L.H. Xu, L.Z. Zhu, Colloids Surf. A 307 (2007) 1–6.

Y.H. Shen, Colloids Surf. A 232 (2004) 143–149.

Q. Zhou, H.P. He, J.X. Zhu, W. Shen, R.L. Frost, P. Yuan, J. Hazard. Mater. 154 (2008) 1025–1032.

H. Yi, X. Zhang, Y.L. Zhao, L.Y. Liu, S.X. Song, Surf. Interface Anal. 48 (2016) 976–980.

D.Q. Zhu, S.A. Xiong, J. Pan, X.L. Zhou, J. Cent. South Univ. (Sci. Technol.) 42 (2011) 279–286.

J. Li, L. Zhu, W. Cai, Colloids Surf. A 281 (2006) 177-183.

P. Baskaralingam, M. Pulikesi, D. Elango, V. Ramamurthi, S. Sivanesan, J. Hazard. Mater. 128 (2006) 138–144.

B.E. Şans, O. Güven, F. Esenli, M.S. Çelik, Appl. Clay Sci. 143 (2017) 415–421.

X.H. Zheng, Bentonite application technology, China University of Geoscience Press, Wuhan, China, 2006.

Acknowledgements

The authors wish to express thanks to National Natural Science Foundation of China (No. 51474161) and Innovation-driven Project of Guangxi Zhuang Autonomous Region (Nos. AA18242003 and AA148242003). The authors would like to thank Co-Innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources of Hunan Province, which supplied us the facilities and funds to fulfill the experiments. The authors would like to thank Sheng-dong Wang from Shiyanjia Laboratory for the graphic abstract.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, Sw., Pan, J., Zhu, Dq. et al. Synthesis, characterization and properties of organically compounded bentonite by molecular intercalation process. J. Iron Steel Res. Int. 27, 1127–1136 (2020). https://doi.org/10.1007/s42243-020-00385-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00385-1