Abstract

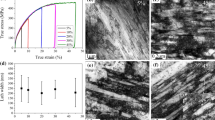

The effect of heat treatment and deep cryogenic treatment on microstructural evolution of low carbon martensitic bearing steel was investigated. The experimental results showed that the lath martensite was obtained by quenching and a few twins as substructures formed in some martensitic laths. The rudiment of sub-interfaces of martensitic lath was formed in the high-density dislocation regions after deep cryogenic treatment; meanwhile, the number of twins increased, especially in the high-density dislocation regions. This phenomenon is due to the increase in internal stress caused by cryogenic treatment. After tempering, the rudiment of sub-interface further evolved into the martensitic lath boundary, and thus the original martensitic laths were refined. The twins formed by cryogenic treatment did not disappear after tempering. In addition, small quantities of annealing twins formed in tempering process. Martensitic laths morphology and substructures in different stages of the heat and deep cryogenic treatment were observed by transmission electron microscopy.

Similar content being viewed by others

References

A. Bhattacharyya, G. Subhash, N. Arakere, Int. J. Fatigue 59 (2014) 102–113.

H.K.D.H. Bhadeshia, Prog. Mater. Sci. 57 (2012) 268–435.

M. Safavi, S.M. Abbasi, R. Mahdavi, J. Iron Steel Res. Int. 19 (2012) No. 2, 67–72.

S. Li, K. Zhao, K. Wang, M. Yang, Mater. Charact. 124 (2017) 154–164.

J.V. Giacchi, O. Fornaro, H. Palacio, Mater. Charact. 68 (2012) 49–57.

S.S. Gill, J. Singh, R. Singh, H. Singh, J. Mater. Eng. Perform. 21 (2012) 1320–1326.

A. Joseph Vimal, A. Bensely, D. Mohanlal Lan, K. Srinivasan, Mater. Manuf. Process. 23 (2008) 369–376.

I. Gunes, A. Cicek, K. Aslantas, F. Kara, Trans. Ind. Inst. Met. 67 (2014) 909–917.

V.G. Gavriljuk, W. Theisen, V.V. Sirosh, E.V. Polshin, A. Kortmann, G.S. Mogilny, Y.N. Petrov, Y.V. Tarusin, Acta Mater. 61 (2013) 1705–1715.

K. Amini, A. Akhbarizadeh, S. Javadpour, Vacuum 86 (2012) 1534–1540.

Y.M. Rhyim, S.H. Han, Y.S. Na, J.H. Lee, Solid State Phenom. 118 (2006) 9–14.

S. Li, N. Min, J. Li, X. Wu, C. Li, L. Tang, Mater. Sci. Eng. A 575 (2013) 51–60.

S. Li, L. Deng, X. Wu, Y. Min, H. Wang, Cryogenics 50 (2010) 754–758.

E.W. Qin, L. Lu, N.R. Tao, J. Tan, K. Lu, Acta Mater. 57 (2009) 6215–6225.

Y.S. Li, Y. Zhang, N.R. Tao, K. Lu, Acta Mater. 57 (2009) 761–772.

C.S. Hong, N.R. Tao, X. Huang, K. Lu, Acta Mater. 58 (2010) 3103–3116.

Y. Zhang, N.R. Tao, K. Lu, Scripta Mater. 60 (2009) 211–213.

A. Oppenkowski, S. Weber, W. Theisen, J. Mater. Process. Technol. 210 (2010) 1949–1955.

D. Das, R. Sarkar, A.K. Dutta, K.K. Ray, Mater. Sci. Eng. A 528 (2010) 589–603.

J.D. Verhoeven, Fundamentals of physical metallurgy, Wiley, New York, USA, 1975.

J. Pešička, R. Kužel, A. Dronhofer, G. Eggeler, Acta Mater. 51 (2003) 4847–4862.

A.I. Tyshchenko, W. Theisen, A. Oppenkowski, S. Siebert, O.N. Razumov, A.P. Skoblik, V.A. Sirosh, Y.N. Petrov, V.G. Gavriljuk, Mater. Sci. Eng. A 527 (2010) 7027–7039.

P.J. Ennis, A. Zielinska-Lipiec, O. Wachter, A. Czyrska-Filemonowicz, Acta Mater. 45 (1997) 4901–4907.

D. Rojas, J. Garcia, O. Prat, L. Agudo, C. Carrasco, G. Sauthoff, A.R. Kaysser-Pyzalla, Mater. Sci. Eng. A 528 (2011) 1372–1381.

P.M. Kelly, J. Nutting, P. Roy, Proc. Roy. Soc. A 259 (1960) 45–58.

T.H. Lee, H.Y. Ha, J.H. Jang, J.Y. Kang, J. Moon, J.Y. Park, C.H. Lee, S.J. Park, Acta Mater. 123 (2017) 197–205.

G. Ghosh, G.B. Olson, J. Phase Equilib. 22 (2001) 199–207.

P.F. Shi, A. Engström, L. Höglund, Q. Chen, S. Bo, J. Ågren, M. Hillert, J. Iron Steel Res. Int. 14 (2007) No. 5, 210–215.

B.P. Sandvik, C.M. Wayman, Metallography 16 (1983) 199–227.

S. Sato, K. Wagatsuma, S. Suzuki, M. Kumagai, M. Imafuku, H. Tashiro, K. Kajiwara, T. Shobuf, Mater. Charact. 83 (2013) 152–160.

J.S. Pan, J.M. Tong, M.B. Tian, Fundamentals of materials science, Tsinghua University Press, Beijing, China, 1998.

H.Y. Yi, F.K. Yan, N.R. Tao, K. Lu, Mater. Sci. Eng. A 647 (2015) 152–156.

S.J. Wang, T. Jozaghi, I. Karaman, R. Arroyave, Y.I. Chumlyakov, Mater. Sci. Eng. A 694 (2017) 121–131.

S. Dash, N. Brown, Acta Metall. 11 (1963) 1067–1075.

Y. Yuan, Y. Gu, C. Cui, T. Osada, Z. Zhong, T. Tetsui, J. Mater. Res. 26 (2011) 2833–2837.

Funding

Funding was provided by Analysis and Testing Foundation of Kunming University of Science and Technology (Grant Nos. 2017M20152230037, 2017M20152230069).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lü, Xy., Wu, Zw., He, X. et al. Effect of deep cryogenic treatment on martensitic lath refinement and nano-twins formation of low carbon bearing steel. J. Iron Steel Res. Int. 27, 105–113 (2020). https://doi.org/10.1007/s42243-019-00356-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-019-00356-1