Abstract

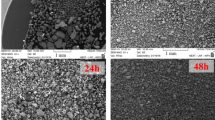

In order to clarify and control the silver defect on surface of cold-rolled sheet of the Ti-stabilized ultra-pure ferrite stainless steel, the distribution of TiN inclusions on the cross section of hot-rolled plate was studied using automated scanning electron microscopy/energy-dispersive X-ray spectroscopy inclusion analysis (ASPEX 1020 system). It was found that the number density decreases sharply from the surface to the center of the hot-rolled plate, whereas the average size increases. Then, the distribution of TiN inclusions on the cross section of continuously cast slab was investigated. Similarly, numerous small-sized TiN inclusions were generated at the subsurface of the slab. The average size rapidly increased and the number density dramatically decreased from the subsurface to 1/4 thickness, while from 1/4 thickness to 1/2 thickness, the increase in average size and the decrease in number density were slight. Thermodynamics results showed that TiN inclusion was formed below the liquidus temperature, which indicated that TiN inclusions could not be formed during secondary refining. Considering the microsegregation of solute elements and the equilibrium of TiN formation during solidification, TiN precipitated in the mushy zone when the solid fraction was close to 0.2. The growth of TiN was analyzed based on the diffusion-controlled growth model. With the increase in cooling rate, the time for TiN growth decreased and the size of TiN inclusions was diminished, which revealed the size distribution of TiN inclusions in the cast slab qualitatively.

Similar content being viewed by others

References

J.F. Almagro, X. Llovet, M.A. Heredia, C. Luna, R. Sánchez, Microchim. Acta 161 (2008) 323–327.

L.Y. Sun, J.S. Li, L.F. Zhang, S.F. Yang, Y.F. Chen, J. Iron Steel Res. Int. 18 (2011) No. 11, 7–11.

C.W. Sinclair, J.D. Mithieux, J.H. Schmitt, Y. Bréchet, Metall. Mater. Trans. A 36 (2005) 3205–3215.

V. Talyan, R.H. Wagoner, J.K. Lee, Metall. Mater. Trans. A 29 (1998) 2161–2172.

S.I. Kim, Y.C. Yoo, Met. Mater. Int. 8 (2002) 7–13.

Y. Furuya, H. Hirukawa, S. Matsuoka, S. Torizuka, H. Kuwahara, Metall. Mater. Trans. A 39 (2008) 2068–2076.

W. Yan, Y.Y. Shan, K. Yang, Metall. Mater. Trans. A 37 (2006) 2147–2158.

L.F. Zhang, B.G. Thomas, ISIJ Int. 43 (2003) 271–291.

L.F. Zhang, J. Iron Steel Res. Int. 13 (2006) No. 4, 1–8.

W. Yang, Y. Zhang, L.F. Zhang, H.J. Duan, L. Wang, J. Iron Steel Res. Int. 22 (2015) 1069–1077.

H. Wada, R.D. Pehlke, Metall. Mater. Trans. B 8 (1977) 443–450.

H.Y. Choi, W.E. Slye, R.J. Fruehan, R.C. Nunnington, Metall. Mater. Trans. B 36 (2005) 537–541.

B. Ozturk, R. Matway, R.J. Fruehan, Metall. Mater. Trans. B 26 (1995) 563–567.

W.Y. Kim, C.O. Lee, C.W. Yun, J.J. Pak, ISIJ Int. 49 (2009) 1668–1672.

J.O. Jo, W.Y. Kim, C.O. Lee, J.J. Pak, ISIJ Int. 51 (2011) 208–213.

J.J. Pak, Y.S. Jeong, I.K. Hong, W.Y. Cha, D.S. Kim, Y.Y. Lim, ISIJ Int. 45 (2005) 1106–1111.

W.Y. Kim, J.O. Jo, T.I. Chung, D.S. Kim, J.J. Pak, ISIJ Int. 47 (2007) 1082–1089.

J.J. Pak, J.T. Yoo, Y.S. Jeong, S.J. Tae, S.M. Seo, D.S. Kim, Y.D. Lee, ISIJ Int. 45 (2005) 23–29.

W.Y. Kim, J.O. Jo, C.O. Lee, D.S. Kim, J.J. Pak, ISIJ Int. 48 (2008) 17–22.

M. Suzuki, R. Yamaguchi, K. Murakami, M. Nakada, ISIJ Int. 41 (2001) 247–256.

Z.Z. Liu, J. Wei, K.K. Cai, ISIJ Int. 42 (2002) 958–963.

Z.Z. Liu, K.J. Gu, K.K. Cai, ISIJ Int. 42 (2002) 950–957.

H. Goto, K. Miyazawa, W. Yamada, K. Tanaka, ISIJ Int. 35 (1995) 708–714.

H. Goto, K. Miyazawa, K. Yamaguchi, S. Ogibayashi, K. Tanaka, ISIJ Int. 34 (1994) 414–419.

M. Wintz, M. Bobadilla, J. Lehmann, H. Gaye, ISIJ Int. 35 (1995) 715–722.

J. Lehmann, P. Rocabois, H. Gaye, J. Non-Cryst. Solid. 282 (2001) 61–71.

Y. Ren, Y. Wang, S. Li, L. Zhang, X. Zuo, S.N. Lekakh, K. Peaslee, Metall. Mater. Trans. B 45 (2014) 1291–1303.

W. Yang, L.F. Zhang, X.H. Wang, Y. Ren, X.F. Liu, Q.L. Shan, ISIJ Int. 53 (2013) 1401–1410.

Y. Liu, L.F. Zhang, H.J Duan, Y. Zhang, Y. Luo, A.N. Conejo, Metall. Mater. Trans. A 47 (2016) 3015–3025.

J. Chen, Manual of chart and data in common use of steel making, The Metallurgical Industry Press, Beijing, China, 2010.

M. Hino, K. Ito, Thermodynamic data for steelmaking, Tohoku University Press, Sendai, Japan, 2010.

G.M. Gulliver, Metallic alloys, Griffen, London, 1922.

E. Scheil, Z. Metallkd. 34 (1942) 70–72.

T.F. Bower, H.D. Brody, M.C. Flemings, Trans. Metall. Soc. AIME 236 (1966) 624–633.

H. Mizukami, T. Suzuki, T. Umeda, Tetsu-to-Hagane 78 (1992) 767–773.

T.W. Clyne, W. Kurz, Metall. Mater. Trans. A 12 (1981) 965–971.

S.K. Choudhary, A. Ghosh, ISIJ Int. 49 (2009) 1819–1827.

H.Y. Liu, H.L. Wang, L. Li, J.Q. Zheng, Y.H. Li, X.Y. Zeng, Ironmak. Steelmak. 38 (2011) 53–58.

Acknowledgements

The authors are grateful for support from the Fundamental Research Funds for the Central Universities (Grant Nos. FRF-TP-15-001C2, FRF-TP-15-067A1 and FRF-TP-17-039A1), Beijing Key Laboratory of Green Recycling and Extraction of Metals (GREM) and the High Quality steel Consortium (HQSC) at the School of Metallurgical and Ecological Engineering at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Duan, Hj., Zhang, Y., Ren, Y. et al. Distribution of TiN inclusions in Ti-stabilized ultra-pure ferrite stainless steel slab. J. Iron Steel Res. Int. 26, 962–972 (2019). https://doi.org/10.1007/s42243-018-0196-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0196-y