Abstract

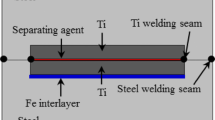

Hot roll bonding was carried out between commercially pure titanium TA2 and high-strength low-alloy steel Q390 using pure Nb or Mo interlayer at 950 °C with a total reduction ratio of 86.7%. Interfacial microstructure and bonding properties of titanium clad steel plates were investigated by electron microscopy and mechanical tests. The results showed β-Ti, TiC and Fe2Ti reaction phases were generated at Ti/steel interface for the clad plates with no interlayer. Inserting Nb or Mo interlayer can effectively suppress the formation of brittle phases, while the weak bonding joint transferred to Nb/steel or Mo/steel interface. And some micro-voids were found at the interface of Nb/steel and Mo/steel. The improved shear strength of clad plates with Nb interlayer might be attributed to the elimination of brittle phases at bonding interface. The small size and little quantities of the micro-voids at Nb/steel interface had a relatively weak effect on shear strength. However, the large number and big size of micro-voids were responsible for the degradation of shear strength for the clad plates with Mo interlayer.

Similar content being viewed by others

References

S. Kundu, S. Sam, S. Chatterjee, Mater. Des. 32 (2011) 2997–3003.

S. Kundu, S. Sam, S. Chatterjee, Mater. Sci. Eng. A 560 (2013) 288–295.

H. Su, X.B. Luo, F. Chai, J.C. Shen, X.J. Sun, F. Lu, J. Iron Steel Res. Int. 22 (2015) 977–982.

Z.A. Luo, G.L. Wang, G.M. Xie, L.P. Wang, K. Zhao, Acta Metall. Sin. (Engl. Lett.) 26 (2013) 754–760.

M. Saboktakin, G.R. Razavi, H. Monajati, Int. J. Appl. Phys. Math.1 (2011) 177–180.

M.X. Xie, L.J. Zhang, G.F. Zhang, J.X. Zhang, Z.Y. Bo, P.C. Li, Mater. Des. 87 (2015) 181–197.

H. Li, C. Zhang, H.B. Liu, M.Q. Li, Trans. Nonferrous Met. Soc. China 25 (2015) 80–87.

D.S. Zhao, J.C. Yan, Y. Wang, S.Q. Yang, Mater. Sci. Eng. A 499 (2009) 282–286.

Y.A. Jing, Y. Qin, X.M. Zang, Y.H. Li, J. Mater. Process. Technol. 214 (2014) 1686–1695.

T. Fukuda, Y. Seino, Tetsu-to-Hagane 75 (1989) 1162–1169.

F. Kurosawa, Surf. Interface Anal. 12 (1988) 203–210.

D. Fujita, K. Yoshihara, Tetsu-to-Hagane 79 (1993) 1088–1094.

S. Yoshiwara, T. Kawanami, K. Suzuki, Y. Kako, Method for producing a clad plate by hot rolling, US, 4831708, 1989.

S. Dziallach, W. Bleck, M. Köhler, G. Nicolini, S. Richter, Adv. Eng. Mater. 11 (2010) 75–81.

A. Elrefaey, W. Tillmann, J. Mater. Process. Technol. 209 (2009) 2746–2752.

P. He, J.C. Feng, Y.Y. Qian, Trans. China Weld. Inst. 23 (2002) No. 1, 76–80.

P. He, D. Liu, Mater. Sci. Eng. A 437 (2006) 430–435.

W.F. Gale, T.C. Totemeier, Smithells metals reference book, Butterworth-Heinemann, 1983.

G. Neumann, C. Tuijn, Self-diffusion and impurity diffusion in pure metals: handbook of experimental data, Pergamon Pr, Amsterdam, 2009.

L. Feng, J.S. Li, L. Huang, H. Chang, Y.W. Cui, L. Zhou, Chin. J. Nonferrous Met. 19 (2009) 1766–1771.

Acknowledgements

The authors thank for the financial support of the International Science and Technology Cooperation Program of China (No. 2015DFR50320) and National High-Tech Research and Development Program of China (No. 2015AA03A501).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chai, Xy., Pan, T., Chai, F. et al. Interlayer engineering for titanium clad steel by hot roll bonding. J. Iron Steel Res. Int. 25, 739–745 (2018). https://doi.org/10.1007/s42243-018-0106-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0106-3