Abstract

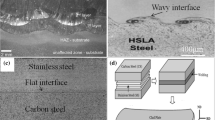

A stainless steel clad plate composed of stainless steel and carbon steel was prepared by vacuum hot rolling process, and its microstructure, especially the bonding interface, was evaluated using an optical microscope, a scanning electron microscope and a transmission electron microscope (TEM). The corresponding mechanical properties were also assessed by means of hardness and shear tests. The results showed a bonding interface formed between stainless steel and carbon steel, which was relatively straight in macroscope but serrated in microscope. Decarburization layer and carbon-enriched layer were distinguished at the side of carbon steel and stainless steel near the interface, respectively, which should be related to diffusion of carbon and alloying elements. The carbon-enriched layer could also be identified as a recombination region, whose microstructure was mainly recognized as martensite by TEM. Consequently, the hardness was the highest at this region. Furthermore, the result of shear test at the bonding interface showed that the shear strength was 395 MPa and the fracture mode was dominated as ductile fracture, indicating the bonding interface with good quality.

Similar content being viewed by others

References

A. Ureña, E. Otero, M.V. Utrilla, C.J. Múnez, J. Mater. Process. Technol. 182 (2007) 624–631.

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa, H. Maza, Mater. Charact. 59 (2008) 447–453.

L. Li, K. Nagai, F.X. Yin, Sci. Technol. Adv. Mater. 9 (2008) 1–11.

L. Li, F.X. Yin, K. Nagai, Mater. Sci. Forum. 675-677 (2011) 439–447.

A. Yahiro, T. Masui, T. Yoshida, D. Doi, ISIJ Int. 31 (1991) 647–654.

B.V. Borts, Mater. Sci. 47 (2012) 689–695.

N.D. Lukaschkin, A.P. Borissow, J. Mater. Process. Technol. 61 (1996) 292–297.

G.M. Xie, Z.A. Luo, G.L. Wang, L. Li, G.D. Wang, Mater. Trans. 52 (2011) 1709–1712.

N.V. Rao, D.S. Sarma, S. Nagarjuna, G.M. Reddy, Mater. Sci. Technol. 25 (2009) 1387–1396.

B. Kurt, A. Calik, Mater. Charact. 60 (2009) 1035–1040.

T. Vigraman, D. Ravindran, R. Narayanasamy, Mater. Des. 34 (2012) 594-602.

A.Z. Hanzaki, P.D. Hodgson, S. Yue, ISIJ Int. 35 (1995) 79–85.

M. Suehiro, Y. Hashimoto, Tetsu-to-Hagane 75 (1989) 1501–1507.

X. Gómez, J. Echeberría, Mater. Sci. Technol. 16 (2000) 187–193.

A.L. Schaeffler, Metal Progr. 106 (1974) 227.

H.E. Boyer, T.L. Gall, Metals handbook, Desk Edition, American Society for Metals, OH, United States, 1985.

Acknowledgements

This work is supported by National High Technology Research and Development Program of China (2015AA03A501).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, J., Ding, H., Luo, Za. et al. Interfacial microstructure and mechanical properties of stainless steel clad plate prepared by vacuum hot rolling. J. Iron Steel Res. Int. 25, 732–738 (2018). https://doi.org/10.1007/s42243-018-0090-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0090-7