Abstract

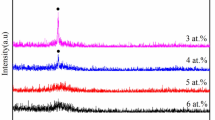

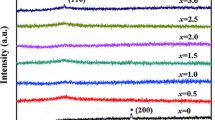

It has been widely accepted that the ultrafast cooling rate is required for the glass formation of amorphous alloys. Here, the larger glass-forming ability (GFA) of Fe76P5(B0.5Si0.3C0.2)19 amorphous alloy was achieved by water quenching at lower cooling rate under argon atmosphere. Cylindrical rods with diameters of 1–2 mm were prepared by water quenching without flux treatment, Cu-mold injection casting, and Cu-mold suction casting, respectively. The influences of the preparation techniques with different cooling rates on GFA, thermal property, and nucleation/growth behavior were examined. The critical diameter of the Fe76P5(B0.5Si0.3C0.2)19 amorphous alloys is 1.7 mm for water quenching while smaller than 1.0 mm for injection casting. Microstructure analysis indicates that the crystallization and solidification processes are quite different between the water-quenched and the injection-cast rods. These findings could deepen fundamental understanding on the relationship between the cooling rate, techniques, and GFA of Fe-based amorphous alloys.

Similar content being viewed by others

References

M.J. Duarte, J. Klemm, S.O. Klemm, K.J.J. Mayrhofer, M. Stratmann, S. Borodin, A.H. Romero, M. Madinehei, D. Crespo, J. Serrano, S.S.A. Gerstl, P.P. Choi, D. Raabe, F.U. Renner, Science 341 (2013) 372–376.

C. Suryanarayana, A. Inoue, Int. Mater. Rev. 58 (2013) 131–166.

W.M. Yang, H.S. Liu, Y.C. Zhao, A. Inoue, K.M. Jiang, J.T. Huo, H.B. Ling, Q. Li, B.L. Shen, Sci. Rep. 4 (2014) 6233.

F. Wang, A. Inoue, Y. Han, S.L. Zhu, F.L. Kong, E. Zanaeva, G.D. Liu, E. Shalaan, F. Al-Marzouki, A. Obaid, J. Alloy. Compd. 723 (2017) 376–384.

T.D. Shen, R.B. Schwarz, Appl. Phys. Lett. 75 (1999) 49–51.

W.H. Wang, Prog. Mater. Sci. 52 (2007) 540–596.

A. Chrobak, V. Nosenko, G. Haneczok, L. Boichyshyn, B. Kotur, A. Bajorek, O. Zivotsky, A. Hendrych, Mater. Chem. Phys. 130 (2011) 603–608.

W.H. Wang, M.X. Pan, D.Q. Zhao, Y. Hu, H.Y. Bai, J. Phys.: Condens. Matter 16 (2004) 3719–3723.

V. Ponnambalam, S.J. Poon, G.J. Shiflet, J. Mater. Res. 19 (2004) 3046–3052.

H. Jian, W. Luo, S. Tao, M. Yan, J. Alloy. Compd. 505 (2010) 315–318.

S.L. Lin, S.F. Chen, J.K. Chen, Y.L. Lin, Intermetallics 18 (2010) 1826–1828.

T. Bitoh, A. Makino, A. Inoue, A.L. Greer, Appl. Phys. Lett. 88 (2006) 182510.

Z.P. Lu, C.T. Liu, J.R. Thompson, W.D. Porter, Phys. Rev. Lett. 92 (2004) 245503.

Z.P. Lu, C.T. Liu, W.D. Porter, Appl. Phys. Lett. 83 (2003) 2581–2583.

J. Schroers, Adv. Mater. 22 (2010) 1566–1597.

W.L. Johnson, G. Kaltenboeck, M.D. Demetriou, J.P. Schramm, X. Liu, K. Samwer, C.P. Kim, D.C. Hofmann, Science 332 (2011) 828–833.

B.L. Shen, M. Akiba, A. Inoue, Appl. Phys. Lett. 88 (2006) 131907.

Z.B. Jiao, H.X. Li, Y. Wu, J.E. Gao, S.L. Wang, S.H. Yi, Z.P. Li, Sci. China, Ser. G 53 (2010) 430–434.

J. Wang, R. Li, N. Hua, L. Huang, T. Zhang, Scripta Mater. 65 (2011) 536–539.

A. Makino, T. Kubota, C.T. Chang, M. Makabe, A. Inoue, Mater. Trans. 48 (2007) 3024–3027.

Q. Li, J. Li, P. Gong, K. Yao, J. Gao, H. Li, Intermetallics 26 (2012) 62–65.

A. Makino, C.T. Chang, T. Kubota, A. Inoue, J. Alloy. Comp. 483 (2009) 616–619.

Q. Li, Metall. Mater. Trans. B 40 (2009) 405–410.

X.H. Lin, W.L. Johnson, J. Appl. Phys. 78 (1995) 6514–6519.

Q. Li, Mater. Lett. 60 (2006) 3113–3117.

Y.H. Liu, D. Wang, K. Nakajima, W. Zhang, A. Hirata, T. Nishi, A. Inoue, M.W. Chen, Phys. Rev. Lett. 106 (2011) 125504.

Y.Q. Cheng, E. Ma, Prog. Mater. Sci. 56 (2011) 379–473.

X. Hu, S.C. Ng, Y.P. Feng, Y. Li, Phys. Rev. B 64 (2001) 172201.

H. Liebermann, C. Graham, P. Flanders, IEEE Trans. Magn. 13 (1977) 1541–1543.

J.H. Martin, B.D. Yahata, J.M. Hundley, J.A. Mayer, T.A. Schaedler, T.M. Pollock, Nature 549 (2017) 365–369.

C.T. Chang, J.H. Zhang, B.L. Shen, W.H. Wang, A. Inoue, J. Mater. Res. 29 (2014) 1217–1222.

H.X. Li, J.E. Gao, Z.B. Jiao, Y. Wu, Z.P. Lu, Appl. Phys. Lett. 95 (2009) 161905.

Z.H. Zeng, H. Jin, M.J. Chen, W.W. Li, L.C. Zhou, X. Xue, Z. Zhang, Small 13 (2017) 1701388.

D.A. Porter, K.E. Esterling, Phase transformations in metals and alloys, 2nd ed., CRC Press, Boca Raton, 1992.

A. Inoue, Mater. Trans. JIM 36 (1995) 866–875.

J. Schroers, Y. Wu, R. Busch, W.L. Johnson, Acta Mater. 49 (2001) 2773–2781.

J. Schroers, W.L. Johnson, R. Busch, Appl. Phys. Lett. 76(2000) 2343–2345.

J. Schroers, A. Masuhr, W.L. Johnson, R. Busch, Phys. Rev. B 60 (1999) 11855.

Acknowledgements

This work was supported by the National Key Research and Development Program of China (Grant No. 2016YFB0300500), National Natural Science Foundation of China (Grant Nos. 51561028 and 51771161), and Ningbo Municipal Natural Science Foundation (Grant No. 2017A610034).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, Jj., Dong, Yq., Bie, Ly. et al. Influences of preparation techniques on glass-forming ability of Fe–P–B–Si–C amorphous alloys. J. Iron Steel Res. Int. 25, 674–679 (2018). https://doi.org/10.1007/s42243-018-0089-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-018-0089-0