Abstract

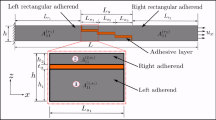

The clinch–adhesive process, which combines mechanical clinching and adhesive bonding, is one of the most applied processes for joining aluminum alloy and steel in the manufacturing of vehicle bodies. In this hybrid process, the clinching joints and adhesive bonds are coupled and influenced by each other, posing challenges to the process design and joining strength evaluation. To understand the influence of the clinching process on the performance of the adhesive layer, this study analyzes the mechanical behavior of clinch–adhesive joints between high-strength steel JSC780 and aluminum alloy A5052-H34 with different stack-up orientations and varying numbers of clinching points. The results reveal that, under the steel-on-top condition, the clinching process causes a discontinuous distribution of the adhesive layer, which significantly decreased the bonding strength. In contrast, under the aluminum-on-top condition, the clinching process has a lesser impact on the distribution of the adhesive layer, resulting in much higher strength than the steel-on-top condition. Simulation models are constructed to quantify the effect of clinching points on the performance of the adhesive layer. The results highlight the need to consider diverse cohesive zone model parameters for the different stack orientations and clinching points in the design of clinch–adhesive aluminum alloy/steel structures.

Similar content being viewed by others

References

Gullino, A., Matteis, P., D’Aiuto, F.: Review of aluminum-to-steel welding technologies for car-body applications. Metals 9(3), 315 (2019)

Geng, P., Ma, Y., Ma, N., Ma, H., Aoki, Y., Liu, H., Fujii, H., Chen, C.: Effects of rotation tool-induced heat and material flow behavior on friction stir lapped Al/steel joint formation and resultant microstructure. Int. J. Mach. Tool Manufact. 174, 103858 (2022)

Hu, S., Haselhuhn, A.S., Ma, Y., Li, Z., Qi, L., Li, Y., Carlson, B.E., Lin, Z.: Effect of external magnetic field on resistance spot welding of aluminium to steel. Sci. Technol. Weld. Joining 27(2), 84–91 (2022)

Schramm, B., Martin, S., Steinfelder, C., Bielak, C.R., Brosius, A., Meschut, G., Tröster, T., Wallmersperger, T., Mergheim, J.: A review on the modeling of the clinching process chain - Part I: design phase. J. Adv. Join. Process. 6, 100133 (2022)

Jiang, H., Liao, Y., Gao, S., Li, G., Cui, J.: Comparative study on joining quality of electromagnetic driven self-piecing riveting, adhesive and hybrid joints for Al/steel structure. Thin-Walled Struct. 164, 107903 (2021)

Jiang, H., Liao, Y., Jing, L., Gao, S., Li, G., Cui, J.: Mechanical properties and corrosion behavior of galvanized steel/Al dissimilar joints. Archiv. Civ. Mech. Eng. 21, 168 (2021)

Niu, S., Ma, Y., Lou, M., Zhang, C., Li, Y.: Joint formation mechanism and performance of resistance rivet welding (RRW) for aluminum alloy and press hardened steel. J. Mater. Process. Technol. 286, 116830 (2020)

Oliveira, J., Ponder, K., Brizes, E., Abke, T., Edwards, P., Ramirez, A.: Combining resistance spot welding and friction element welding for dissimilar joining of aluminum to high strength steels. J. Mater. Process. Technol. 273, 116192 (2019)

Xia, H., Li, L., Tan, C., Yang, J., Li, H., Song, W., Zhang, K., Wang, Q., Ma, N.: In situ SEM study on tensile fractured behavior of Al/steel laser welding-brazing interface. Mater Design 224, 111320 (2022)

Min, J., Wan, H., Carlson, B.E., Lin, J., Sun, C.: Application of laser ablation in adhesive bonding of metallic materials: a review. Opt. Laser Technol. 128, 106188 (2020)

Wu, T., Zhang, Q., Zhang, C., Li, Y., Carlson, B.E.: Process variables influencing solder reinforced adhesive (SRA) performance. J. Manuf. Process. 31, 440–452 (2018)

Zhu, C., Wan, H., Min, J., Mei, Y., Lin, J., Carlson, B.E., Maddela, S.: Application of pulsed Yb: Fiber laser to surface treatment of Al alloys for improved adhesive bonded performance. Opt. Lasers Eng 119, 65–76 (2019)

Liu, Y., Han, L., Zhao, H., Liu, X.: Numerical modelling and experimental investigation of the Riv-Bonding process. J. Mater. Process. Technol. 288, 116914 (2021)

Neugebauer, R., Kraus, C., Dietrich, S.: Advances in mechanical joining of magnesium. CIRP Ann. Manuf. Techn. 57(1), 283–286 (2008)

Zhu, X., Li, Y., Ni, J., Lai, X.: Curing-induced debonding and its influence on strength of adhesively bonded joints of dissimilar materials. J. Manuf. Sci. Eng. 138(6), 061005 (2016)

Zvorykina, A., Sherepenko, O., Neubauer, M., Jüttner, S.: Dissimilar metal joining of aluminum to steel by hybrid process of adhesive bonding and projection welding using a novel insert element. J. Mater. Process. Technol. 282, 116680 (2020)

Zhu, X., Yang, X., Li, Y., Carlson, B.E.: Reinforcing cross-tension strength of adhesively bonded joints using metallic solder balls. Int. J. Adhes. Adhes. 68, 263–272 (2016)

Abe, Y., Maeda, T., Yoshioka, D., Mori, K.I.: Mechanical clinching and self-pierce riveting of thin three sheets of 5000 series Aluminium alloy and 980 MPa grade cold rolled ultra-high strength steel. Materials (Basel). 13(21), 4741 (2020)

Mori, K., Abe, Y.: A review on mechanical joining of aluminium and high strength steel sheets by plastic deformation. Int. J. Lightweight Mater. Manuf. 1(1), 1–11 (2018)

Etemadi, S., Hahn, O., Roll, K.: Simulation of hybrid joining technologies using the example of clinch-bonding. Key Eng. Mater. 504–506, 777–782 (2012)

Neugebauer, R., Israel, M., Mayer, B., Fricke, H.: Numerical and experimental studies on the clinch-bonding and riv-bonding process. Key Eng. Mater. 504–506, 771–776 (2012)

Ma, Y., Abe, Y., Geng, P., Akita, R., Ma, N., Mori, K.: Adhesive dynamic behavior in the clinch-bonding process of aluminum alloy A5052–H34 and advanced high-strength steel JSC780. J. Mater. Process. Technol. 305, 117602 (2022)

Gerstmann, T., Awiszus, B.: Hybrid joining: numerical process development of flat-clinch-bonding. J. Mater. Process. Technol. 277, 116421 (2020)

Lei, L., He, X., Zhao, D., Zhang, Y., Gu, F., Ball, A.: Clinch-bonded hybrid joining for similar and dissimilar copper alloy, aluminium alloy and galvanised steel sheets. Thin Walled Struct. 131, 393–403 (2018)

Moroni, F.: Fatigue behaviour of hybrid clinch-bonded and self-piercing rivet bonded joints. J. Adhes. 95(5–7), 577–594 (2019)

Meschut, G., Janzen, V., Olfermann, T.: Innovative and highly productive joining technologies for multi-material lightweight car body structures. J. Mater. Eng. Perform. 23(5), 1515–1523 (2014)

Yang, B., Shan, H., Liang, Y., Ma, Y., Niu, S., Zhu, X., Li, Y.: Effect of adhesive application on friction self-piercing riveting (F-SPR) process of AA7075-T6 aluminum alloy. J. Mater. Process. Technol. 299, 117336 (2022)

Zhuang, W., Shi, H., Li, M.: Curing effects on forming and mechanical performance of clinch-adhesive joints of dissimilar materials between AA5754 Aluminum Alloy and Q235 steel. J. Adhes. 99(1), 1–33 (2023)

Fricke, H., Vallée, T.: Numerical modeling of hybrid-bonded joints. J. Adhes. 92(7–9), 652–664 (2016)

Campilho, R.D.S.G.: Strength Prediction of Adhesively-Bonded Joints. CRC Press, Boca Raton (2017)

Bayramoglu, S., Demir, K., Akpinar, S.: Investigation of internal step and metal part reinforcement on joint strength in the adhesively bonded joint: experimental and numerical analysis. Theor. Appl. Fract. Mech. 108, 102613 (2020)

de Almeida, F.J.S., Campilho, R.D.S.G., Silva, F.J.G.: Strength prediction of T-peel joints by a hybrid spot-welding/adhesive bonding technique. J. Adhesion. 94(3), 181–198 (2016)

El Zaroug, M., Kadioglu, F., Demiral, M., Saad, D.: Experimental and numerical investigation into strength of bolted, bonded and hybrid single lap joints: Effects of adherend material type and thickness. Int. J. Adhes. Adhes. 87, 130–141 (2018)

Balawender, T., Sadowski, T., Golewski, P.: Numerical analysis and experiments of the clinch-bonded joint subjected to uniaxial tension. Adv. Funct. Mater. 64, 270–272 (2012)

Ibrahim, A.H., Cronin, D.S.: Mechanical testing of adhesive, self-piercing rivet, and hybrid jointed aluminum under tension loading. Int. J. Adhes. Adhes. 113, 103066 (2022)

Ramalho, L.D.C., Campilho, R.D.S.G., Belinha, J., da Silva, L.F.M.: Static strength prediction of adhesive joints: a review. Int. J. Adhes. Adhes. 96, 102451 (2020)

da Silva, L.F.M., Campilho, R.D.S.G.: Advances in numerical modelling of adhesive joints. Briefs in Applied Sciences and Technology. Springer, Heidelberg (2012)

LSTC: LS-DYNA® Keyword user's manual volume II Material Modles. Dev. r:5583 (2014)

Acknowledgements

The authors would like to acknowledge the financial supports of the National Key Research and Development Program of China (2022YFB3402200), Young Elite Scientists Sponsorship Program by CAST (2022-2024QNRC001), Shanghai Pujiang Program (22PJ1407200), Joint Research Collaborators and Strategic International Co-Creation Research on Global Diversity and Inclusion of Joining and Welding Research Institute in Osaka University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all the authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, Y., Akita, R., Abe, Y. et al. Mechanical Performance Evaluation of Multi-Point Clinch–Adhesive Joints of Aluminum Alloy A5052-H34 and High-Strength Steel JSC780. Automot. Innov. 6, 340–351 (2023). https://doi.org/10.1007/s42154-023-00234-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42154-023-00234-3