Abstract

Highly thermally conductive polymer-based composites are becoming increasingly important for effectively removing the accumulated heat of thermal management devices. However, interfacial thermal resistance (ITR) seriously affects the heat transfer performance of composites. Herein, after mildly modifying the commercial graphite, copper nanoparticles (CuNPs) are deposited on the surface of modified graphite (MGr) by chemically reducing. And the CuNPs-deposited MGr (MGr/Cu) hybrids are mixed with epoxy resin to prepare composites. Through the improved interfacial contact and interconnection between CuNPs and MGr, the heat conduction pathways will be easy to form in epoxy matrix. And the MGr/Cu hybrids exhibit well compatibility with epoxy matrix. Consequently, the resultant composite exhibits a high thermal conductivity of 4.57 W m−1 K−1 at 50 wt% MGr/Cu loading. Fitting the experimental value with Foygel nonlinear model further reveals that the ITR is 3.92 × 10−6 m2 K W−1 for MGr/Cu/epoxy composites, which decreases by 27.94% than that of Gr/epoxy composites. Moreover, our composite displays well heat dissipation potential in thermal management application. This strategy provides an effective guidance for reducing the ITR inside polymer composites to prepare thermal management materials.

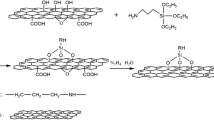

Graphic Abstract

The thermal conductivity is improved via thermally conductive Cu bridges between modified graphite and the improved compatibility between graphite and epoxy.

Similar content being viewed by others

References

Jiang F, Cui S, Rungnim C, Song N, Shi L, Ding P (2019) Control of a dual-cross-linked boron nitride framework and the optimized design of the thermal conductive network for its thermoresponsive polymeric composites. Chem Mater 31: 7686–7695. https://doi.org/10.1021/acs.chemmater.9b02551

Yin Y, Jiang B, Zhu X, Meng L, Huang Y (2018) Investigation of thermostability of modified graphene oxide/methylsilicone resin nanocomposites. Engineered Science. https://doi.org/10.30919/es8d762

Hu X, Wu H, Lu X, Liu S, Qu J (2021) Improving thermal conductivity of ethylene propylene diene monomer/paraffin/expanded graphite shape-stabilized phase change materials with great thermal management potential via green steam explosion. Adv Compos Hybrid Mater 4: 478–491. https://doi.org/10.1007/s42114-021-00300-6

He L (2021) Improve thermal conductivity of polymer composites via conductive network. Nat Nanotechnol 13: 1–2. https://doi.org/10.30919/esmm5f460

Yuan H, Wang Y, Li T, Ma P, Zhang S, Du M, Chen M, Dong W, Ming W (2018) Highly thermal conductive and electrically insulating polymer composites based on polydopamine-coated copper nanowire. Compos Sci Technol 164: 153–159. https://doi.org/10.1016/j.compscitech.2018.05.046

Zhang F, Feng Y, Feng W (2020) Three-dimensional interconnected networks for thermally conductive polymer composites: Design, preparation, properties, and mechanisms. Mater Sci Eng, R 142. https://doi.org/10.1016/j.mser.2020.100580

Yan X, Liu J, Khan MA, Sheriff S, Vupputuri S, Das R, Sun L, Young DP, Guo Z (2020) Efficient solvent-free microwave irradiation synthesis of highly conductive polypropylene nanocomposites with lowly loaded carbon nanotubes. ES Materials & Manufacturing. https://doi.org/10.30919/esmm5f716

Song J, Zhang Y (2020) Vertically aligned silicon carbide nanowires/reduced graphene oxide networks for enhancing the thermal conductivity of silicone rubber composites. Composites, Part A. https://doi.org/10.1016/j.compositesa.2020.105873

Zhou Y, Liu F, Chen C-Y (2019) Use of BN-coated copper nanowires in nanocomposites with enhanced thermal conductivity and electrical insulation. Adv Compos Hybrid Mater 2: 46–50. https://doi.org/10.1007/s42114-019-00077-9

Xin G, Sun H, Hu T, Fard HR, Sun X, Koratkar N, Borca-Tasciuc T, Lian J (2014) Large-area freestanding graphene paper for superior thermal management. Adv Mater 26: 4521–4526. https://doi.org/10.1002/adma.201400951

Zhang Y, Park M, Park SJ (2019) Implication of thermally conductive nanodiamond-interspersed graphite nanoplatelet hybrids in thermoset composites with superior thermal management capability. Sci Rep 9: 2893. https://doi.org/10.1038/s41598-019-39127-z

Chen F, Xiao H, Peng ZQ, Zhang ZP, Rong MZ, Zhang MQ (2021) Thermally conductive glass fiber reinforced epoxy composites with intrinsic self-healing capability. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-021-00303-3

Yan H, Dai X, Ruan K, Zhang S, Shi X, Guo Y, Cai H, Gu J (2021) Flexible thermally conductive and electrically insulating silicone rubber composite films with BNNS@Al2O3 fillers. Adv Compos Hybrid Mater 4: 36–50. https://doi.org/10.1007/s42114-021-00208-1

Feng C-P, Bai L, Bao R-Y, Liu Z-Y, Yang M-B, Chen J, Yang W (2017) Electrically insulating POE/BN elastomeric composites with high through-plane thermal conductivity fabricated by two-roll milling and hot compression. Adv Compos Hybrid Mater 1: 160–167. https://doi.org/10.1007/s42114-017-0013-2

Liu Q, He X-B, Ren S-B, Zhang C, Ting-Ting L, Qu X-H (2014) Thermophysical properties and microstructure of graphite flake/copper composites processed by electroless copper coating. J Alloys Compd 587: 255–259. https://doi.org/10.1016/j.jallcom.2013.09.207

Li X, Wu B, Li Y, Alam MM, Chen P, Xia R, Lin CT, Qian J (2021) Construction of oriented interconnected BNNS skeleton by self‐growing CNTs leading high thermal conductivity. Adv Mater Interfaces 8. https://doi.org/10.1002/admi.202001910

Gao Q, Pan Y, Zheng G, Liu C, Shen C, Liu X (2021) Flexible multilayered MXene/thermoplastic polyurethane films with excellent electromagnetic interference shielding, thermal conductivity, and management performances. Adv Compos Hybrid Mater 4: 274–285. https://doi.org/10.1007/s42114-021-00221-4

Zhang X, Xia X, You H, Wada T, Chammingkwan P, Thakur A, Taniike T (2020) Design of continuous segregated polypropylene/Al2O3 nanocomposites and impact of controlled Al2O3 distribution on thermal conductivity. Compos Part A- Appl Sci131. https://doi.org/10.1016/j.compositesa.2020.105825

Wang X, Wu P (2017) Preparation of highly thermally conductive polymer composite at low filler content via a self-assembly process between polystyrene microspheres and boron nitride nanosheets. ACS Appl Mater Interfaces 9: 19934–19944. https://doi.org/10.1021/acsami.7b04768

Huang X, Zhi C, Jiang P, Golberg D, Bando Y, Tanaka T (2013) Polyhedral oligosilsesquioxane-modified boron nitride nanotube based epoxy nanocomposites: an ideal dielectric material with high thermal conductivity. Adv Funct Mater 23: 1824–1831. https://doi.org/10.1002/adfm.201201824

Shen X, Wang Z, Wu Y, Liu X, Kim J-K (2016) Effect of functionalization on thermal conductivities of graphene/epoxy composites. Carbon 108: 412–422. https://doi.org/10.1016/j.carbon.2016.07.042

Kim JY, Lee J-H, Grossman J.C. (2012) Thermal transport in functionalized graphene. ACS Nano 6: 9050–9057. https://doi.org/10.1021/nn3031595

Hu D, Ma W (2020) Nanocellulose as a sustainable building block to construct eco-friendly thermally conductive composites. Industrial & Engineering Chemistry Research 59: 19465–19484. https://doi.org/10.1021/acs.iecr.0c04319

Yao Y, Zeng X, Pan G, Sun J, Hu J, Huang Y, Sun R, Xu JB, Wong CP (2016) Interfacial engineering of silicon carbide nanowire/cellulose microcrystal paper toward high thermal conductivity. ACS Appl Mater Interfaces 8: 31248–31255. https://doi.org/10.1021/acsami.6b10935

Ren L, Li Q, Lu J, Zeng X, Sun R, Wu J, Xu J-B, Wong C-P (2018) Enhanced thermal conductivity for Ag-deposited alumina sphere/epoxy resin composites through manipulating interfacial thermal resistance. Compos Part A- Appl Sci107: 561–569. https://doi.org/10.1016/j.compositesa.2018.02.010

Ruan K, Shi X, Guo Y, Gu J (2020) Interfacial thermal resistance in thermally conductive polymer composites: A review. Compos Commun 22. https://doi.org/10.1016/j.coco.2020.100518

Wang F, Yao Y, Zeng X, Huang T, Sun R, Xu J, Wong C-P (2016) Highly thermally conductive polymer nanocomposites based on boron nitride nanosheets decorated with silver nanoparticles. RSC Adv 6: 41630–41636. https://doi.org/10.1039/c6ra00358c

Pan G, Yao Y, Zeng X, Sun J, Hu J, Sun R, Xu JB, Wong CP (2017) Learning from natural nacre: constructing layered polymer composites with high thermal conductivity. ACS Appl Mater Interfaces 9: 33001–33010. https://doi.org/10.1021/acsami.7b10115

Chen C, Xue Y, Li Z, Wen Y, Li X, Wu F, Li X, Shi D, Xue Z, Xie X (2019) Construction of 3D boron nitride nanosheets/silver networks in epoxy-based composites with high thermal conductivity via in-situ sintering of silver nanoparticles. Chem Eng J 369: 1150–1160. https://doi.org/10.1016/j.cej.2019.03.150

Wang S, Cheng Y, Wang R, Sun J, Gao L (2014) Highly thermal conductive copper nanowire composites with ultralow loading: toward applications as thermal interface materials. ACS Appl Mater Interfaces 6: 6481–6486. https://doi.org/10.1021/am500009p

Vu MC, Bach Q-V, Nguyen DD, Tran TS, Goodarzi M (2019) 3D interconnected structure of poly(methyl methacrylate) microbeads coated with copper nanoparticles for highly thermal conductive epoxy composites. Compos Part B-Eng 175. https://doi.org/10.1016/j.compositesb.2019.107105

Chen L, Yuan T, Ni R, Yue Q, Gao B (2019) Multivariate optimization of ciprofloxacin removal by polyvinylpyrrolidone stabilized NZVI/Cu bimetallic particles. Chem Eng J 365: 183–192. https://doi.org/10.1016/j.cej.2019.02.051

Saberi A, Golestani-Fard F, Willert-Porada M, Simon R, Gerdes T, Sarpoolaky H (2008) Improving the quality of nanocrystalline MgAl2O4 spinel coating on graphite by a prior oxidation treatment on the graphite surface. J Eur Ceram Soc 28: 2011–2017. https://doi.org/10.1016/j.jeurceramsoc.2008.01.020

Park CM, Jo YN, Park JW, Yu J-S, Kim J-S, Choi J, Kim Y-J (2014) Anodic performances of surface-treated natural graphite for lithium ion capacitors. Bull Korean Chem Soc 35: 2630–2634. https://doi.org/10.5012/bkcs.2014.35.9.2630

Liu S, Zhao B, Jiang L, Zhu Y-W, Fu X-Z, Sun R, Xu J-B, Wong C-P (2018) Core–shell Cu@rGO hybrids filled in epoxy composites with high thermal conduction. J Mater Chem C 6: 257–265. https://doi.org/10.1039/c7tc04427e

Yao X, Gao X, Jiang J, Xu C, Deng C, Wang J (2018) Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites. Compos Part B-Eng 132: 170–177. https://doi.org/10.1016/j.compositesb.2017.09.012

Yan F, Liu L, Li M, Zhang M, Xiao L, Ao Y (2018) Preparation of carbon nanotube/copper/carbon fiber hierarchical composites by electrophoretic deposition for enhanced thermal conductivity and interfacial properties. J Mater Sci 53: 8108–8119. https://doi.org/10.1007/s10853-018-2115-9

Peng J, Chen B, Wang Z, Guo J, Wu B, Hao S, Zhang Q, Gu L, Zhou Q, Liu Z, Hong S, You S, Fu A, Shi Z, Xie H, Cao D, Lin CJ, Fu G, Zheng LS, Jiang Y, Zheng N (2020) Surface coordination layer passivates oxidation of copper. Nature 586: 390–394. https://doi.org/10.1038/s41586-020-2783-x

Duguet T, Gavrielides A, Esvan J, Mineva T, Lacaze-Dufaure C (2019) DFT simulation of XPS reveals Cu/epoxy polymer interfacial bonding. J Phys Chem C 123: 30917–30925. https://doi.org/10.1021/acs.jpcc.9b07772

Jasuja K, Berry V (2009) Implantation and growth of dendritic gold nanostructures on graphene derivatives: electrical property tailoring and raman enhancement. ACS Nano 3: 2358–2366. https://doi.org/10.1021/nn900504v

Mahadevi AS, Sastry GN (2012) Cation−π Interaction: Its Role and Relevance in Chemistry, Biology, and Material Science. Chem Rev 113: 2100–2138. https://doi.org/10.1021/cr300222d

Kim Y, Qian Y, Kim M, Ju J, Baeck S-H, Shim SE (2017) A one-step process employing various amphiphiles for an electrically insulating silica coating on graphite. RSC Adv 7: 24242–24254. https://doi.org/10.1039/c7ra03049e

Yao Y, Zeng X, Sun R, Xu JB, Wong CP (2016) Highly Thermally Conductive Composite Papers Prepared Based on the Thought of Bioinspired Engineering. ACS Appl Mater Interfaces 8: 15645–15653. https://doi.org/10.1021/acsami.6b04636

Dang R, Song L, Dong W, Li C, Zhang X, Wang G, Chen X (2014) Synthesis and self-assembly of large-area Cu nanosheets and their application as an aqueous conductive ink on flexible electronics. ACS Appl Mater Interfaces 6: 622–629. https://doi.org/10.1021/am404708z

Zhang Y, Heo Y-J, Son Y-R, In I, An K-H, Kim B-J, Park S-J (2019) Recent advanced thermal interfacial materials: A review of conducting mechanisms and parameters of carbon materials. Carbon 142: 445–460. https://doi.org/10.1016/j.carbon.2018.10.077

Zhu C, Fu Y, Liu C, Liu Y, Hu L, Liu J, Bello I, Li H, Liu N, Guo S, Huang H, Lifshitz Y, Lee ST, Kang Z (2017) Carbon dots as fillers inducing healing/self-healing and anticorrosion properties in polymers. Adv Mater 29. https://doi.org/10.1002/adma.201701399

Choi S, Yang J, Kim Y, Nam J, Kim K, Shim SE (2014) Microwave-accelerated synthesis of silica nanoparticle-coated graphite nanoplatelets and properties of their epoxy composites. Compos Sci Technol 103: 8–15. https://doi.org/10.1016/j.compscitech.2014.08.003

Tu H, Ye L (2009) Thermal conductive PS/graphite composites. Polym Adv Technol 20: 21–27. https://doi.org/10.1002/pat.1236

Sun J, Zhang X, Du Q, Murugadoss V, Wu D, Guo Z (2021) The contribution of conductive network conversion in thermal conductivity enhancement of polymer composite: a theoretical and experimental study. ES Materials & Manufacturing. https://doi.org/10.30919/esmm5f450

Song N, Cao D, Luo X, Wang Q, Ding P, Shi L (2020) Highly thermally conductive polypropylene/graphene composites for thermal management. Compos Part A- Appl Sci135. https://doi.org/10.1016/j.compositesa.2020.105912

Liu J, Guo Y, Weng C, Zhang H, Zhang Z (2020) High thermal conductive epoxy based composites fabricated by multi-material direct ink writing. Compos Part A- Appl Sci129. https://doi.org/10.1016/j.compositesa.2019.105684

Xu X, Zhou J, Chen J (2019) Thermal transport in conductive polymer–based materials. Adv Funct Mater 30. https://doi.org/10.1002/adfm.201904704

Barani Z, Mohammadzadeh A, Geremew A, Huang CY, Coleman D, Mangolini L, Kargar F, Balandin AA (2019) Thermal properties of the binary‐filler hybrid composites with graphene and copper nanoparticles. Adv Funct Mater. https://doi.org/10.1002/adfm.201904008

Haghgoo M, Ansari R, Hassanzadeh-Aghdam MK, Nankali M (2019) Analytical formulation for electrical conductivity and percolation threshold of epoxy multiscale nanocomposites reinforced with chopped carbon fibers and wavy carbon nanotubes considering tunneling resistivity. Compos Part A- Appl Sci126. https://doi.org/10.1016/j.compositesa.2019.105616

Funding

The research is financially supported by the National Science Foundation for Distinguished Young Scholars of China (Grant No. 51925403), Major Research plan of the National Natural Science Foundation of China (Grant No. 91934302), and the National Science Foundation of China (21676052, 21606042). Funding for exploratory projects of the National Key Laboratory of Chemical Engineering (SKL-ChE-20T07).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Xu, F., Bao, D., Cui, Y. et al. Copper nanoparticle-deposited graphite sheets for highly thermally conductive polymer composites with reduced interfacial thermal resistance. Adv Compos Hybrid Mater 5, 2235–2246 (2022). https://doi.org/10.1007/s42114-021-00367-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00367-1