Abstract

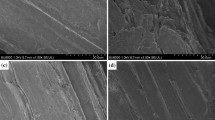

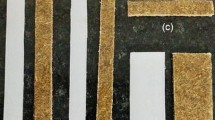

The present work investigating the effect of acetylation treatment on the plain woven banana fabric (PWBF) in a polyvinyl alcohol (PVA) matrix, which includes the banana fabric strength and fabric pull-out. This type of fabric treatment is normally used to improve the mechanical and thermo-mechanical behavior of composites. The raw PWBFs are treated with different acetylation percentages of concentrations (i.e., 2, 4, 6, 8, and 10) for 4 h at room temperature. The mechanical properties (i.e., tensile, flexural, and impact), thermo-mechanical behavior (i.e., storage modulus and loss modulus), surface morphology after tensile test, and water and biodegradability test of treated and untreated PWBF were investigated. The experimental results showed that the acetylation treatment was able to successfully remove hemicellulose, lignin, moisture content, waste impurities, and other unwanted particles from the PWBF surface and improve the mechanical and thermo-mechanical behavior of PWBF. In order to investigate PWBF/PVA internal bonding, the nature of fabric pull-out analysis was also carried out. It was found that the PWBF/PVA interfacial behavior increased after the acetylation treatment. The experimental results showed that treated composite was taken more time to complete biodegradable in natural soil and untreated composite specimen absorbed more water rate. In reality, the most favorable acetylation concentration was 6% in terms of maximum strength, a strong area of contact and bonding between PWBF/PVA, this is usually due to the reduction of hemicellulose, lignin, moisture content, impurities, and amorphous parts of the fabric.

Graphical abstract

Similar content being viewed by others

References

Alavudeen A, Rajini N, Karthikeyan S, Thiruchitrambalam M (2015) Mechanical properties of banana/kenaf fiber reinforced hybrid polyester composites of woven fabrics and random orientation. Mater Des 1980–2015(66):246–257. https://doi.org/10.1016/j.matdes.2014.10.067

Mohammed L, Mohammed Ansari MNM, Fei Ling Pua FL (2015) Natural fiber reinforced polymer composites and its applications. Polym Sci Mater 03:322–327. https://www.hindawi.com/journals/ijps/2015/243947/

Satishkumar S, Suresh AV, Nagamadhu M, Krishna M (2017) The effect of alkaline treatment on their properties of jute fiber mat and its vinyl ester composites. Mater Today 04:3371–3379. https://doi.org/10.1016/j.matpr.2017.02.225

Asim M, Jawaid M, Abdan K, Ishak MRW (2016) Effect of alkali and silane treatments on mechanical and fiber matrix bond strength of kenaf and pineapple leaf fibers. Bionic Eng 13:426–435. https://link.springer.com/article/10.1016/S1672-6529(16)60315-3

Yeo JS, Kim OY, Hwang SH (2017) Effect of lignin on the volume shrinkage and mechanical properties of a styrene unsaturated polyester lignin ternary composite system. Compos Part B 130:167–173. https://doi.org/10.1016/j.compositesb.2017.07.084

Nagamadhu M, Mohan KGC, Jeyaraj P (2014) Effect of stacking sequence on mechanical properties of neem wood veneer plastic composites. AIP Conf Proc 1943:020029. https://doi.org/10.1063/1.5029605

Das S (2017) Mechanical properties of waste paper jute fabrics reinforced polyester resin matrix hybrid composites. Carbohyd Polym 172:60–67. https://doi.org/10.1016/j.carbpol.2017.05.036

Nagamadhu M, Mohan Kumar GC, Jeyaraj P, Kivade SB (2019) Characterization and mechanical properties of sisal fabric reinforced polyvinyl alcohol green composites: effect of composition and loading direction. Mater Res Express 06:125320. https://iopscience.iop.org/article/10.1088/2053-1591/ab56b3/meta

Vinod Kumar T, Chandrasekaran M, Padmanabhan S (2017) Characteristics and mechanical properties of reinforced polymer composites. Eng Appl Sci 12:2450–2454. http://www.arpnjournals.org/jeas/research-papers/rp-2017/jeas-0417-5920.pdf

Yahayaa R, Sapuan SM, Jawaid M, Leman Z, Zainudin ES (2015) Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf aramid hybrid laminated composites. Mater Des 67:173–179. https://doi.org/10.1016/j.matdes.2014.11.024

Singha JIP, Dhawan V, Singh S, Jangid J (2017) Study of effect of surface treatment on mechanical properties of natural fiber reinforced composite. Mater Des 04:2793–2799. https://doi.org/10.1016/j.matpr.2017.02.158

Barreto ACH, Rosa DS, Fechines PBA, Mazzetto S (2011) Properties of sisal fibers treated by alkali solution and their application into cardanol based bio-composites. Appl Sci Manuf 42(5):492–500. https://doi.org/10.1016/j.compositesa.2011.01.008

Arumuga PV, Uthavakumar M, Manikandan V, Rajini N, Jeyaraj. (2014) Influence of red mud on the mechanical, damping and chemical resistance properties of banana/polyester hybrid composites. Mater Des 64:270–279. https://doi.org/10.1016/j.matdes.2014.07.020

Rokbi M, Osmani H, Imad A, Benseddiq N (2011) Effect of chemical treatment flexural properties of natural fiber reinforced polyester composites. Procedia Eng 10:2092–2097. https://doi.org/10.1016/j.proeng.2011.04.346

Siddika S, Manusura F, Hasan M, Hassan A (2014) Effect of reinforcement and chemical treatment of fiber on the properties of jute coir fiber reinforced hybrid polypropylene composites. Fiber Polym 15:1023–1028. https://doi.org/10.1007/s12221-014-1023-0

De Araujo R, Lima A, Cavalcanti DK, de Souza e Silva Neto J (2019) Effect of surface treatments on interfacial properties of natural intralaminar hybrid composites. Adv Opt Metrology 41:1–12. https://doi.org/10.1002/pc.25371

Mohan Kumar GC, Nagamadhu M, Jeyaraj P (2019) Mechanical and tribological behavior of woven sisal fabric. Tribol Ind 41:622–633. http://13.232.72.61:8080/jspui/handle/123456789/3346

Jorge De Souza E, Neto S, De Araujio R, Lima A (2018) Effect of chemical treatment on the thermal properties of hybrid natural fiber reinforced composites. J Appl Polym Sci 136:47154. https://doi.org/10.1002/app.47154

Arrakhiz FZ, Elachaby M, Bouhfid R, Vaudreuil S (2012) Mechanical and thermal properties of polypropylene reinforced with Alfa fiber under different chemical treatment. Mater Des 35:318–322. https://doi.org/10.1016/j.matdes.2011.09.023

Mohan KGC, Jeyaraj P, Nagamadhu M (2019) Dynamic mechanical analysis of glutaraldehyde cross linked polyvinyl alcohol under tensile mode. AIP Conf Proc 2057:020017. https://doi.org/10.1063/1.5085588

Senthilraja P, Sarala R, Godwin AA, Seshadhri. (2020) Effect of acetylation technique on mechanical behavior and durability of palm fiber vinyl ester composites. Materials today proceeding 21:634–637. https://doi.org/10.1016/j.matpr.2019.06.729

Naik P, Pradhan S, Sahoo P, Acharya SK (2020) Study of mechanical behavior of raw and chemical treated bio-filled composites and its effect on moisture absorption. Mater Today Proc 26:1936–1940. https://doi.org/10.1016/j.matpr.2020.02.423

Madhu P, Sanjay MR, Jawaid M, Siengchin S, Khan A, Pruncu C (2020) A new study on effect of various chemical treatments on agave americana fiber for composite reinforcement. Polym Testing 85:25–34. https://doi.org/10.1016/j.polymertesting.2020.106437

Karthi N, Kumaresan K, Sathish S, Gokulkumar S, Prabhu L, Vigneshkumar N (2020) An overview on natural fiber reinforced hybrid composites, chemical treatments and its applications areas. Mater Today Proc 07:2828–2834. https://doi.org/10.1016/j.matpr.2020.01.011

Sanjay MR, Yogesha B (2017) Studies on natural/glass fiber reinforced polymer hybrid composite. Mater Today Proc 04:2739–2747. https://doi.org/10.1016/j.matpr.2017.02.151

Essabir H, Raji M, Bouhfid R, El Kacem Qaiss A (2016) Nanoclay and natural fibers based hybrid composites, mechanical, morphological, thermal and rheological properties. Nanoclay reinforced polymer composites, 02, 29–49. Springer, Singapore. https://doi.org/10.1007/978-981-10-0950-1-2

Madhu P, Jawid M (2018) Characterization and properties of natural fiber polymer composites. J Clean Prod 172:566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Nagamadhu M, Jeyaraj P, Mohan Kumar GC (2020) Influence of textile properties on dynamic mechanical behavior of epoxy composite reinforced with woven sisal fabrics. Sadhana 45:1–10. https://link.springer.com/article/10.1007/s12046-019-1249-z

Venkateshwaran N, Elaya PA, Alavudeen A, Thiruchitrambalam M (2011) Mechanical and water absorption behavior of banana/sisal reinforced hybrid composites. Mater Des 32:4017–4021. https://doi.org/10.1016/j.matdes.2011.03.002

Mohan KGC, Jeyaraj P, Nagamadhu M (2020) Influence of glutaraldehyde on dynamic properties of poly (vinyl alcohol) polymer. Emerg Mater Res 09:168–179. https://doi.org/10.1680/jemmr.18.00059

Neto JSS, Lima RAA, Cavalcanti DKK, Souza JPB (2018) Effect of chemical treatment on the thermal properties of hybrid natural fiber reinforced composites. Polymer science 136:10–19. https://doi.org/10.1002/app.47154

Mohana KD, Sreeramulu D, Venteshwar RP (2019) Alkali treatment effect on mechanical, thermal, morphological and spectroscopy studies on abutilon indicum fiber reinforced composites. Nat Fibers 12:51–62. https://doi.org/10.1080/15440478.2019.1598917

Muhammed HH, Mohamed STH, Ahmad Ariffin H, Ain Shah UM (2019) Effects of fiber treatment on mechanical properties of kenaf fiber reinforced composites”. Mater Res Technol 08:3327–3337. https://doi.org/10.1016/j.jmrt.2019.04.012

Jain D, Kamboj I, Bera TK, Kang AS, Singla RK (2019) Experimental and numerical investigations on the effect of alkaline hornification on the hydrothermal ageing of agave natural fiber composites. Heat Mass Transf 130:431–439. https://doi.org/10.1016/j.ijheatmasstransfer.2018.10.106

Liu Y, Xie J, Wu N, Ma Y (2019) Characterization of natural cellulose fiber from corn stalk waste subjected to different surface treatments. Korean Ceram Soc 26:4707–4719. https://link.springer.com/article/10.1007/s10570-019-02429-6

Sreekumar PA, Saiah R, Saiter JM (2018) Thermal behavior of chemically treated and untreated sisal fiber reinforced composites fabricated by resin transfer molding. Compos Interfaces 15:629–650. https://www.researchgate.net/publication/261586537

Bharath KN, Madhu P, Yashas Gowda TG, Sanjay MR, Kushvaha V, Siengchin S (2018) Alkaline effect on characterization of discarded waste of moringa oleifera fiber as a potential eco-friendly reinforcement for biocomposites. Polym Environ 28:2823–2836. https://link.springer.com/article/10.1007/s10924-020-01818-4

Sumesh KR, Kanthavel K, Kavimani V (2020) Peanut oil cake-derived cellulose fiber: Extraction, application of mechanical and thermal properties in pineapple/flax natural fiber composites. Biol Macromol 150:775–785. https://www.sciencedirect.com/science/article/abs/pii/S014181301939779X

Shao X, He L, Ma L Water absorption and FTIR analysis of three type natural fiber reinforced composites. In 2015 2nd International Forum on Electrical Engineering and Automation (IFEEA 2015) 11:269–272. Atlantis Press. https://link.springer.com/article/25847632%20(1)

Jayamani E, Loong TG, Bakri MKB (2020) Comparative study of fourier transforms infrared spectroscopy (FTIR) analysis of natural fibres treated with chemical, physical and biological methods. Polymer 1605–1629. https://link.springer.com/article/10.1007/s00289-019-02824-w

Nagamadhu M, Jeyaraj P, Mohan Kumar GC (2019) Characterization and mechanical properties of sisal fabric reinforced polyvinyl alcohol green composites: effect of composition and loading direction. Mater Res Express 6:1–21. https://doi.org/10.1088/2053-1591/ab56b3

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kivade, S.B., Gunge, A., Nagamadhu, M. et al. Mechanical and dynamic mechanical behavior of acetylation-treated plain woven banana reinforced biodegradable composites. Adv Compos Hybrid Mater 5, 144–158 (2022). https://doi.org/10.1007/s42114-021-00247-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-021-00247-8