Abstract

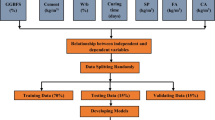

Many studies have proven that the employ of alkali activated concrete (AAC) will efficiently furnish eco-friendly and sustainable solutions for the hitches coupled with Portland cement-based cementitious concretes. There are limited studies on the development of soft computing models on the strength characteristics of AAC structural masonry applications. This paper presents an experimental and soft computing modeling result on the strength performances (compression, split tension and flexure) on the AAC structural masonry block elements. The AAC mixes were developed incorporating the Ground Granulated Blast Furnace slag (75%), finely ground waste glass (15%), and fly-ash (10%) as cementing ingredients and the liquid sodium silicate and sodium hydroxide solution (activator modulus = 1.25) were used as alkaline activator solution. A total of 18 different mix proportion designs were developed at different combinations of aggregates, namely Natural Coarse Aggregates (NCA), Recycled Coarse Aggregates (RCA), River Sand Fine Aggregates (RSFA), Crusher Dust Fine Aggregates (CDFA) and for every mix 6 individual sample results were obtained, respectively, for compression, split tension and flexure tests, i.e., a total of 108 results from laboratory tests; out of which 70% of sample results are utilized for training, 25% for testing and 5% for validation of the artificial neural network (ANN) models obtained using MATLAB environment. The model performances were evaluated through the statistical indicators such as RMSE, R2, CC, SI and NSE to choose the efficient/best model. The outcome from this research work effectively proposes a novel type of soft computing model to select the optimum ingredients in producing the desired quality alkali-activated structural masonry block mixes by the use of non-congenital waste aggregates through reduced manual labor efforts and to conserve precious time spent otherwise in the testing laboratories.

Similar content being viewed by others

Data availability

The data will be made available by the authors on request.

References

Asteris, P. G., Chronopoulos, M. P., Chrysostomou, C. Z., Varum, H., Plevris, V., Kyriakides, N., & Silva, V. (2014). Seismic vulnerability assessment of historical masonry structural systems. Engineering Structures, 62–63, 118–134. https://doi.org/10.1016/j.engstruct.2014.01.031

Asteris, P. G., Lourenço, P. B., Hajihassani, M., Adami, C. E. N., Lemonis, M. E., Skentou, A. D., Marques, R., Nguyen, H., Rodrigues, H., & Varum, H. (2021). Soft computing-based models for the prediction of masonry compressive strength. Engineering Structures, 248, 113276. https://doi.org/10.1016/j.engstruct.2021.113276

Balas, C. E., Koç, M. L., & Tür, R. (2010). Artificial neural networks based on principal component analysis, fuzzy systems and fuzzy neural networks for preliminary design of rubble mound breakwaters. Applied Ocean Research, 32, 425–433. https://doi.org/10.1016/j.apor.2010.09.005

Bendell, J. (2018). Deep adaptation: A map for navigating climate tragedy. Institute of Leadership and Sustainability (IFLAS), 2, 1–16.

Cavicchioli, R., Ripple, W. J., Timmis, K. N., Azam, F., Bakken, L. R., Baylis, M., Behrenfeld, M. J., Boetius, A., Boyd, P. W., Classen, A. T., Crowther, T. W., Danovaro, R., Foreman, C. M., Huisman, J., Hutchins, D. A., Jansson, J. K., Karl, D. M., Koskella, B., Mark Welch, D. B., … Webster, N. S. (2019). Scientists’ warning to humanity: Microorganisms and climate change. Nature Reviews Microbiology, 17, 569–586. https://doi.org/10.1038/s41579-019-0222-5

Ceroni, F., Pecce, M., Sica, S., & Garofano, A. (2012). Assessment of seismic vulnerability of a historical masonry building. Buildings, 2, 332–358. https://doi.org/10.3390/buildings2030332

Deo, M. C. (2010). Artificial neural networks in coastal and ocean engineering. Indian Journal of Marine Sciences, 39, 589–596.

Flower, D. J. M., & Sanjayan, J. G. (2007). Greenhouse gas emissions due to concrete manufacture, handbook of low carbon. Concrete, 12, 1–16. https://doi.org/10.1016/B978-0-12-804524-4.00001-4

He, Z., Zhu, X., Wang, J., Mu, M., & Wang, Y. (2019). Comparison of CO2 emissions from OPC and recycled cement production. Construction and Building Materials, 211, 965–973. https://doi.org/10.1016/j.conbuildmat.2019.03.289

Ilangovana, R., Mahendrana, N., & Nagamanib, K. (2008). Strength and durability properties of concrete containing quarry rock dust as fine aggregate. ARPN Journal of Engineering and Applied Sciences, 3, 20–26.

IS 2386(Part IV) (1963). Methods of test for aggregates for concrete-Mechanical Properties. 1–28.

IS:2386(Part III) (1963). Method of test for aggregate for concrete. 1–17.

IS:383 (2016). Coarse and fine aggregate for concrete-specification. 1–21.

IS-2185 (Part-1) (2005). Concrete masonry units, part 1: Hollow and solid concrete blocks (Third Revision), 4th ed., Bureau of Indian Standards, New Delhi.

IS-2386:Part-I (1963). Indian standard method of test for aggregate for concrete; Part I-particle size and shape. 1–26.

Jagadish, K. S. (2015). Structural masonry (1st ed.). I.K. International Publishing House Pvt. Ltd.

Jain, A., Rao, S. (2019). Application of soft computing technique for prediction of wave transmission characteristics of coastal vegetation, in: Proceedings of HYDRO-2019, B S Publicaton Hyderabad, Hyderabad. pp. 2956–2963.

Kaveh, A., Bakhshpoori, T., & Hamze-Ziabari, S. M. (2018). GMDH-based prediction of shear strength of FRP-RC beams with and without stirrups. Computers and Concrete, An International Journal, 22(2), 197–207.

Kaveh, A., Gholipour, Y., & Rahami, H. (2008). Optimal design of transmission towers using genetic algorithm and neural networks. International Journal of Space Structures. https://doi.org/10.1260/026635108785342073

Kaveh, A., Khalegi, A. (1998). Prediction of strength for concrete specimens using artificial neural networks, Advances in Engineering Computational Technology. 165–171.

Kaveh, A., & Lranmanesh, A. (1998). Comparative study of backpropagation and improved counter propagation neural nets in structural analysis and optimization. International Journal of Space Structures, 13(4), 177–85.

Kaveh, A., Servati, H. (2001). Design of double layer grids using backpropagation neural networks. Computers & Structures www.elsevier.com/locate/compstruc. 2023 Jan 21;79(17):1561–8.

Li, Z., Delsaute, B., Lu, T., Kostiuchenko, A., Staquet, S., & Ye, G. (2021). A comparative study on the mechanical properties, autogenous shrinkage and cracking proneness of alkali-activated concrete and ordinary Portland cement concrete. Construction and Building Materials, 292, 1–11. https://doi.org/10.1016/j.conbuildmat.2021.123418

Mandal, S., Rao, S., Harish, N., & Lokesha. (2012). Damage level prediction of non-reshaped berm breakwater using ANN, SVM and ANFIS models. International Journal of Naval Architecture and Ocean Engineering, 4, 112–122. https://doi.org/10.2478/ijnaoe-2013-0082

Marathe, S., & Mithanthaya, I. R. (2022). Investigations on eco-friendly masonry structural elements developed using slag-fly ash-glass powder-based alkali activated concrete. International Journal of Masonry Research and Innovation, 7, 310–325. https://doi.org/10.1504/IJMRI.2022.122517

Marathe, S., Mithanthaya, I. R., Mithun, B. M., Shetty, S., & Akarsh, P. K. (2020). Performance of slag-fly ash based alkali activated concrete for paver applications utilizing powdered waste glass as a binding ingredient. International Journal of Pavement Research and Technology. https://doi.org/10.1007/s42947-020-0173-2

Marathe, S., Mithanthaya, I. R., & Shetty, S. (2019). Strength behaviour of masonry blocks produced using green concrete. In N. Neithalath & B. B. Das (Eds.), Sustainable construction and building materials (pp. 33–40). Springer. https://doi.org/10.1007/978-981-13-3317-0_4

Marathe, S., Rao, N. B. S., & Kumar, A. (2017). Behaviour of concrete masonry blocks provided with a reinforcement layer. International Journal of Earth Sciences and Engineering, 10, 1007–1011. https://doi.org/10.21276/ijee.2017.10.0511

Marathe, S., Shetty, T. S., Mithun, B. M., & Ranjith, A. (2021). Strength and durability studies on air cured alkali activated pavement quality concrete mixes incorporating recycled aggregates. Case Studies in Construction Materials, 15, 1–13. https://doi.org/10.1016/j.cscm.2021.e00732

Mehta, K. P. (2001). Reducing the environmental impact of concrete. ACI Concrete International, 23, 61–66. https://doi.org/10.1016/s1351-4210(05)70693-4

Mithun, B. (2017). Performance of alkali activated slag concrete mixes incorporating copper slag as fine aggregate. National Institute of Technology Karnataka Surtathkal. 112, 837–844.

Mithun, B. M., & Narasimhan, M. C. (2015). Performance of alkali activated slag concrete mixes incorporating copper slag as fine aggregate. Journal of Cleaner Production, 112, 837–844. https://doi.org/10.1016/j.jclepro.2015.06.026

Mithun, B. M., Narasimhan, M. C., Palankar, N., & Ravishankar, A. U. (2015). Flexural fatigue performance of alkali activated slag concrete mixes incorporating copper slag as fine aggregate. SSP-Journal of Civil Engineering, 10, 7–18. https://doi.org/10.1515/sspjce-2015-0001

Morsy, M. S., Rashad, A. M., & Shebl, S. S. (2008). Mechanism of effect of elevated temperature on compressive strength of cement mortar. Building Research Journal, 56, 173–185.

Palankar, N. (2016). Performance of alkali activated concrete mixes with steel slag as coarse Aggregate for Rigid pavements. National Institute of Technology Karnataka Surtathkal.

Palankar, N., Ravi Shankar, A. U., & Mithun, B. M. (2015). Studies on eco-friendly concrete incorporating industrial waste as aggregates. International Journal of Sustainable Built Environment. https://doi.org/10.1016/j.ijsbe.2015.05.002

Palankar, N., Ravi Shankar, A. U., & Mithun, B. M. (2016). Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. Journal of Cleaner Production, 129, 437–448. https://doi.org/10.1016/j.jclepro.2016.04.033

Prakash, K. S., & Rao, C. H. (2016). Study on compressive strength of quarry dust as fine aggregate in concrete. Advances in Civil Engineering. https://doi.org/10.1155/2016/1742769

Rashad, A. M. (2013a). Properties of alkali-activated fly ash concrete. Iranian Journal of Materials Science & Engineering, 10, 57–64.

Rashad, A. M. (2013b). A comprehensive overview about the influence of different additives on the properties of alkali-activated slag—a guide for Civil Engineer. Construction and Building Materials, 47, 29–55. https://doi.org/10.1016/j.conbuildmat.2013.04.011

Rashad, A. M., Zeedan, S. R., & Hassan, H. A. (2012). A preliminary study of autoclaved alkali-activated slag blended with quartz powder. Construction and Building Materials, 33, 70–77. https://doi.org/10.1016/j.conbuildmat.2011.12.104

Reddy, N., Kuntoji, G., Rao, S., Mandal, S., Student, P. (2016). Prediction of wave transmission using ANN for submerged reef of tandem breakwater, In: International Conference on Emerging Trends in Engineering. pp. 137–142. https://doi.org/10.15680/IJIRSET.2016.0505522.

Schwarz, N., Cam, H., & Neithalath, N. (2008). Influence of a fine glass powder on the durability characteristics of concrete and its comparison to fly ash. Cement and Concrete Composites, 30, 486–496. https://doi.org/10.1016/j.cemconcomp.2008.02.001

Shetty, M. S., & Jain, A. K. (2018). Concrete technology: Theory and practice. S. Chand Publishing House.

Shetty, S. S., Marathe, S., & Mithanthaya, I. R. (2021). Comparative studies on flexural strength of conventional and alkali-activated masonry elements designed to field mix. Trends in Civil Engineering and Challenges for Sustainability. Select Proceedings of CTCS 2019 73–84. https://doi.org/10.1007/978-981-15-6828-2_7

Svozil, D., Kvasnička, V., & Pospíchal, J. (1997). Introduction to multi-layer feed-forward neural networks. Chemometrics and Intelligent Laboratory Systems, 39, 43–62. https://doi.org/10.1016/S0169-7439(97)00061-0

Venugopal, K., Radhakrishna, Sasalatti, V. (2016). Development of alkali activated geopolymer masonry blocks, In: IOP Conference Series: Materials Science and Engineering. pp. 1–12. https://doi.org/10.1088/1757-899X/149/1/012072.

Acknowledgements

All the major works were done in the department laboratory of the Civil Engineering Department, NMAM Institute of Technology, Nitte. Financial support was provided by Nitte Education Trust, i.e., NMAMIT research grant bearing Grant number: NMAMIT/RF/2017/08 and ref number- 2017/NMAMIT/Dean(R&D)/81 dated 05/10/2017 for carrying out the experimental works.

Funding

The funding details are as follows and it has been incorporated in the acknowledgement section. Financial support was provided by Nitte Education Trust, i.e., NMAMIT research grant bearing Grant number: NMAMIT/RF/2017/08 and ref number- 2017/NMAMIT/Dean(R&D)/81 dated 05/10/2017

Author information

Authors and Affiliations

Contributions

AJ: Investigation, Data accusation, Methodology, Formal analysis. SM: Supervision, Writing- Original draft preparation, Resources, Conceptualization,. Visualization, Validation. AS: Writing- Reviewing and Editing, Formal analysis.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jain, A., Marathe, S. & S, A. Soft computing modeling on air-cured slag-fly ash-glass powder-based alkali activated masonry elements developed using different industrial waste aggregates. Asian J Civ Eng 24, 1515–1527 (2023). https://doi.org/10.1007/s42107-023-00584-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42107-023-00584-7