Abstract

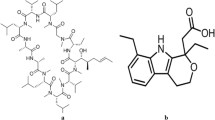

In this paper, we demonstrate the use of machine learning to optimize the continuous flow process of a crucial intermediate in the production of Nemonoxacin. Our focus is to achieve the good yield and enantioselectivity in the construction of chiral methyl group utilize the initial 29 experimental datasets and consider six important variables. Employing Single-Objective Bayesian optimization (SOBO), we achieved an impressive predicted yield of up to 89.7%, which is consistent with the experimental results, with a yield of 89.5%. Additionally, A Multi-Objective Bayesian Optimization (MOBO) algorithm, namely qNEHVI, to strike a balance between yield and enantioselectivity in the continuous flow system is applied. The algorithm’s prediction, with a yield of 81.8% and enantioselectivity of 97.85%, was experimentally validated, yielding 83.8% and 97.2%, respectively. This study effectively demonstrates that Bayesian optimization is a powerful tool for optimizing the continuous process in the production of active pharmaceutical ingredients (APIs).

Similar content being viewed by others

Data and code availability

The data and the source code for this study are accessible on GitHub at https://github.com/zhaisilong/flow. You can also find a comprehensive description of our model construction in the supplementary information.

References

Poole RM (2014) Drugs 74:1445–1453

Chotikanatis K, Kohlhoff SA, Hammerschlag MR (2014) Antimicrob Agents Chemother 58:1800–1801

Chen YH, Liu CY, Lu JJ, King CHR, Hsueh PR (2009) J Antimicrob Chemother 64:1226–1229

Adam HJ, Laing NM, King CR, Lulashnyk B, Hoban DJ, Zhanel GG (2009) Antimicrob Agents Chemother 53:4915–4920

TaiGen Biotechnology Co Ltd (2023) TaiGen Biotechnology receives marketing approval from the Taiwan Food and Drug Administration for Taigexyn (nemonoxacin) in Taiwan. https://www.taigenbiotech.com.tw/

TaiGen Biotechnology Co Ltd (2013) TaiGen Biotechnology receives qualified infectious disease product and fast track designations from the U.S. Food and Drug Administration for nemonoxacin (Taigexyn(Rm)). http://www.taigenbiotech.com.tw/

TaiGen Biotechnology Co Ltd (2010) Patent: US2010/152452

Stueckler C, Hermsen P, Ritzen B, Vasiloiu M, Poechlauer P, Steinhofer S, Pelz A, Zinganell C, Felfer U, Boyer S (2019) Org Process Res Dev 23:1069–1077

Shields BJ, Stevens J, Li J, Parasram M, Damani F, Alvarado JIM, Janey JM, Adams RP, Doyle AG (2021) Nature 590:89–96

Schweidtmann AM, Clayton AD, Holmes N, Bradford E, Bourne RA, Lapkin AA (2018) Chem Eng J 352:277–282

Kondo M, Wathsala H, Salem MS, Ishikawa K, Hara S, Takaai T, Washio T, Sasai H, Takizawa S (2022) Commun Chem 5:148

Kershaw OJ, Clayton AD, Manson JA, Barthelme A, Pavey J, Peach P, Mustakis J, Howard RM, Chamberlain TW, Warren NJ, Bourne RA (2023) Chem Eng J 451:138443

Daulton S, Balandat M, Bakshy E (2021) Adv Neural Inf Process Syst 34:2187–2200

Chow S, Liver S, Nelson A (2018) Streamlining bioactive molecular discovery through integration and automation. Nat Rev Chem 2:174–183

Clayton AD, Manson JA, Taylor CJ, Chamberlain TW, Taylor BA, Clemens G, Bourne RA (2019) Algorithms for the self-optimisation of chemical reactions. React Chem Eng 4:1545–1554

Messalas A, Kanellopoulos Y, Makris C (2019) Proc 10th int conf IISA. IEEE, New York, pp 1–7

Rozemberczki B, Watson L, Bayer PET, Yang HT, Kiss O, Nilsson S, Sarkar R (2022) arXiv. https://doi.org/10.48550/arXiv.2202.05594

Chen H, Covert IC, Lundberg SM, Lee SI (2023) Nat Mach Intell 5:590–601

Wang Y, Chen TY, Vlachos DG (2021) J Chem Inf Model 61:5312–5319

Feurer M, Eggensperger K, Falkner S, Lindauer M, Hutter F (2022) J Mach Learn Res 23:11936–11996

Acknowledgements

This work was supported by the Ten-thousand Talents Program of Zhejiang Province(2021R52013), the grants from National Natural Science Foundation of China (82274003), Shaoxing Science and Technology Plan Project (No. 2022A14027).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, J., Zhao, C., Sheng, L. et al. Continuous flow process optimization aided by machine learning for a pharmaceutical intermediate. J Flow Chem (2024). https://doi.org/10.1007/s41981-024-00318-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41981-024-00318-z