Abstract

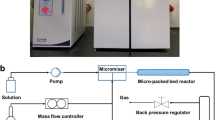

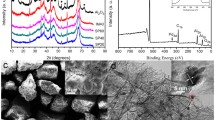

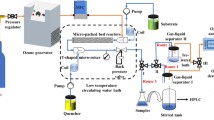

The matching of the micro-dispersion method and the reaction kinetics is of the utmost importance for the fast and strongly exothermic nitration reaction. Taken as an example to discuss this issue, a synthesis of 3,4-dichloronitrobenzene via the nitration of o-dichlorobenzene with mixed acid of nitric acid and sulfuric acid was conducted in continuous-flow reactors in this work. Through combining the adiabatic reaction environment, the use of a micropacked-bed reactor, and introducing partial product circulation, it successfully achieved the matching of the micro-dispersion state and the reaction kinetic characteristics. The good two-phase dispersion state can be maintained throughout the micropacked-bed reactor and the reaction can be completed within 5 s with above 89% selectivity under adiabatic condition. Furthermore, the reaction activation energy was conveniently obtained by processing the temperature distribution data, providing a fundamental to realize a reliable design of the nitration reaction process with high efficiency and inherent safety.

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

References

Bogdan A, McQuade DT (2009) A biphasic oxidation of alcohols to aldehydes and ketones using a simplified packed-bed microreactor. Beilstein J. Org. Chem. 5:17. https://doi.org/10.3762/bjoc.5.17

Chen P, Shen C, Qiu M, Wu J, Bai Y, Su Y (2020) Synthesis of 5-fluoro-2-nitrobenzotrifluoride in a continuous-flow millireactor with a safe and efficient protocol. J. Flow. Chem. 10(1):207–218. https://doi.org/10.1007/s41981-019-00068-3

Cheng X, Zhang S (1998) Resparch on the conventional nitration and adiabatic nitration for o-dichlorobenzene mixed acids. J. Shenyang Inst. Technol. 17(1):102–106

Cox PR, Strachan AN (1971) Two phase nitration of chlorobenzene. Chem. Eng. Sci. 26(7):1013–1018. https://doi.org/10.1016/0009-2509(71)80014-3

Du C, Wang P, Hu Y, Zhang J, Luo G (2020) Liquid-liquid mass transfer enhancement in milliscale packed beds. Ind. Eng. Chem. Res. 59(9):4048–4057. https://doi.org/10.1021/acs.iecr.9b04225

Gage JR, Guo X, Tao J, Zheng C (2012) High output continuous nitration. Org. Process. Res. Dev. 16(5):930–933. https://doi.org/10.1021/op2003425

Gutmann B, Cantillo D, Kappe CO (2015) Continuous-flow technology: a tool for the safe manufacturing of active pharmaceutical ingredients. Angew. Chem. Int. Ed. 54(23):6688–6728. https://doi.org/10.1002/anie.201409318

Halder R, Lawal A, Damavarapu R (2007) Nitration of toluene in a microreactor. Catal. Today 125(1–2):74–80. https://doi.org/10.1016/j.cattod.2007.04.002

Jiang D, Jue W (1998) 3,4-Dichloronitrobenzene synthesis process improvement. Zhejiang Chem. Ind. 29(4):25–28

von Keutz T, Cantillo D, Kappe CO (2019) Enhanced mixing of biphasic liquid-liquid systems for the synthesis of gem-dihalocyclopropanes using packed bed reactors. J. Flow. Chem. 9(1):27–34. https://doi.org/10.1007/s41981-018-0026-1

Kulkarni AA (2014) Continuous flow nitration in miniaturized devices. Beilstein J. Org. Chem. 10:405–424. https://doi.org/10.3762/bjoc.10.38

Li L, Yao C, Jiao F, Han M, Chen G (2017) Experimental and kinetic study of the nitration of 2-ethylhexanol in capillary microreactors. Chem. Eng. Process. 117:179–185. https://doi.org/10.1016/j.cep.2017.04.005

Lu YC, Zhu S, Wang K, Luo GS (2016) Simulation of the mixing process in a straight tube with sudden changed cross-section. Chin. J. Chem. Eng. 24(6):711–718. https://doi.org/10.1016/j.cjche.2016.01.011

Movsisyan M, Delbeke EIP, Berton JKET, Battilocchio C, Ley SV, Stevens CV (2016) Taming hazardous chemistry by continuous flow technology. Chem. Soc. Rev. 45(18):4892–4928. https://doi.org/10.1039/c5cs00902b

Noel T, Kuhn S, Musacchio AJ, Jensen KF, Buchwald SL (2011) Suzuki-Miyaura cross-coupling reactions in flow: multistep synthesis enabled by a microfluidic extraction. Angew. Chem. Int. Ed. 50(26):5943–5946. https://doi.org/10.1002/anie.201101480

Olah GA, Malhotra R, Narang SC (1989) Nitration: methods and mechanisms. Wiley, New York

Plutschack MB, Pieber B, Gilmore K, Seeberger PH (2017) The Hitchhiker’s guide to flow chemistry. Chem. Rev. 117(18):11796–11893. https://doi.org/10.1021/acs.chemrev.7b00183

Quadros PA, Oliveira NMC, Baptista C (2005) Continuous adiabatic industrial benzene nitration with mixed acid at a pilot plant scale. Chem. Eng. J. 108(1–2):1–11. https://doi.org/10.1016/j.cej.2004.12.022

Russo D, Tomaiuolo G, Andreozzi R, Guido S, Lapkin AA, Di Somma I (2019) Heterogeneous benzaldehyde nitration in batch and continuous flow microreactor. Chem. Eng. J. 377:120346. https://doi.org/10.1016/j.cej.2018.11.044

Sang L, Feng X, Tu J, Xie B, Luo G, Zhang J (2020) Investigation of external mass transfer in micropacked bed reactors. Chem. Eng. J. 393:124793. https://doi.org/10.1016/j.cej.2020.124793

Schöfield K (1980) Aromatic Nitration. Cambridge University, Cambridge

Sharma M, Acharya RB, Kulkarni AA (2019) Exploring the steady operation of a continuous pilot plant for the di-nitration reaction. Chem. Eng. Technol. 42(10):2241–2251. https://doi.org/10.1002/ceat.201900140

Su Y, Zhao Y, Chen G, Yuan Q (2010) Liquid-liquid two-phase flow and mass transfer characteristics in packed microchannels. Chem. Eng. Sci. 65(13):3947–3956. https://doi.org/10.1016/j.ces.2010.03.034

Su Y, Zhao Y, Jiao F, Chen G, Yuan Q (2011) The intensification of rapid reactions for multiphase systems in a microchannel reactor by packing microparticles. AICHE J. 57(6):1409–1418. https://doi.org/10.1002/aic.12367

Su Y, Chen G, Yuan Q (2011) Ideal micromixing performance in packed microchannels. Chem. Eng. Sci. 66(13):2912–2919. https://doi.org/10.1016/j.ces.2011.03.024

Tu J, Sang L, Cheng H, Ai N, Zhang J (2020) Continuous hydrogenolysis of n-diphenylmethyl groups in a micropacked-bed reactor. Org. Process. Res. Dev. 24(1):59–66. https://doi.org/10.1021/acs.oprd.9b00416

Wang W, Yu Z (2017) Continuous synthesis of 3,4-dichloronitrobenzene. Zhejiang Chem. Ind. 48(5):28–31

Wang K, Li L, Xie P, Luo G (2017) Liquid-liquid microflow reaction engineering. React. Chem. Eng. 2(5):611–627. https://doi.org/10.1039/c7re00082k

Wen Z, Jiao F, Yang M, Zhao S, Zhou F, Chen G (2017) Process development and scale-up of the continuous flow nitration of trifluoromethoxybenzene. Org. Process. Res. Dev. 21(11):1843–1850. https://doi.org/10.1021/acs.oprd.7b00291

Wen Z, Yang M, Zhao S, Zhou F, Chen G (2018) Kinetics study of heterogeneous continuous-flow nitration of trifluoromethoxybenzene. React. Chem. Eng. 3(3):379–387. https://doi.org/10.1039/c7re00182g

Yao XJ, Zhang Y, Du LY, Liu JH, Yao JF (2015) Review of the applications of microreactors. Renew. Sust. Energ. Rev. 47:519–539. https://doi.org/10.1016/j.rser.2015.03.078

Yu Z, Zhou P, Liu J, Wang W, Yu C, Su W (2016) Continuous-flow process for selective mononitration of 1-methyl-4-(methylsulfonyl)benzene. Org. Process. Res. Dev. 20(2):199–203. https://doi.org/10.1021/acs.oprd.5b00374

Yu Z, Xu Q, Liu L, Wu Z, Huang J, Lin J, Su W (2020) Dinitration of o-toluic acid in continuous-flow: process optimization and kinetic study. J. Flow. Chem. 10(2):429–436. https://doi.org/10.1007/s41981-020-00078-6

Yue J (2018) Multiphase flow processing in microreactors combined with heterogeneous catalysis for efficient and sustainable chemical synthesis. Catal. Today 308:3–19. https://doi.org/10.1016/j.cattod.2017.09.041

Zhang JS, Zhang CY, Liu GT, Luo GS (2016) Measuring enthalpy of fast exothermal reaction with infrared thermography in a microreactor. Chem. Eng. J. 295:384–390. https://doi.org/10.1016/j.cej.2016.01.100

Zhang C, Zhang J, Luo G (2020) Kinetics determination of fast exothermic reactions with infrared thermography in a microreactor. J. Flow. Chem. 10(1):219–226. https://doi.org/10.1007/s41981-019-00071-8

Acknowledgments

This work was supported by the National Natural Science Foundation of China under Grant (21422603, U1662120, 21978152).

Funding

This work was supported by the National Natural Science Foundation of China under Grant (21422603, U1662120, 21978152).

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Code availability

Not applicable

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Article Highlights

• Study apparent reaction kinetic of the nitration of o-dichlorobenzene under various micro-dispersion methods.

• Proposed strategy combination of the adiabatic and micropacked-bed reactor for process intensification and control.

• Enable rapid determination of activation energy by the measurement of adiabatic temperature rise.

Supplementary Information

ESM 1

(DOCX 6660 kb)

Rights and permissions

About this article

Cite this article

Lan, Z., Lu, Y. Continuous nitration of o-dichlorobenzene in micropacked-bed reactor: process design and modelling. J Flow Chem 11, 171–179 (2021). https://doi.org/10.1007/s41981-020-00132-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41981-020-00132-3