Abstract

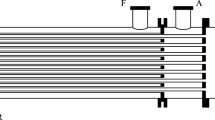

The CFD analysis was conducted using Ansys 19.0 for bayonet tubes with different construction materials and constant wall temperatures. It was used to determine what Reynolds number and material would be suitable for use in a parabolic solar water heater and heat exchanger. The results of the analysis showed that cold water flows along a central tube and exits through an annular portion, and five different materials were used to construct the interior of the bayonet tube. The Reynolds number is used to calculate short circuit and total heat transmission, Nusselt number, friction factor, and effectiveness. Heat transmission from short circuits increases with increased thermal conductivity, causing effectiveness to decrease with corresponding Reynolds numbers. Optimal results are obtained when CPVC is used as the inner part of the tube, with the highest efficiency for bayonet solar collectors reaching 0.89 at a Reynolds number of 75 and the minimum efficiency using an inner CPVC tube being 0.26. These results provide valuable reference points for engineers and designers when designing parabolic solar collectors and heat exchangers that utilize bayonet tubes.

Similar content being viewed by others

Data availability

The data that support the findings of this research are available upon request from the corresponding author. Due to the sensitive nature of the data and to ensure the privacy and confidentiality of the participants, access to the data will be granted after a formal request and with the approval of the appropriate ethical review board. Requests for data should be addressed to [Nishant Singh and email: kaalkhanday@gmail.com].

Abbreviations

- A :

-

Surface area of the tube (m2)

- ρ :

-

Density (kg m−3)

- d :

-

Diameter (m)

- L c :

-

Clearance length of the bayonet tube (m)

- T :

-

Temperature (K)

- L :

-

Length of the bayonet tube (m)

- ṁ :

-

Mass flow rate of the flowing fluid (kg s−1)

- v :

-

Average velocity of fluid (m s−1)

- T w :

-

Wall temperature of tube (K)

- τ :

-

Shear stress (Pa)

- u :

-

Initial velocity of fluid (m s−1)

- k :

-

Thermal conductivity (W m−1 K−1)

- c p :

-

Specific heat capacity (KJ kg−1 K−1)

- Nuo :

-

Overall Nusselt number

- μ :

-

Dynamic viscosity (Pa s)

- ε :

-

Effectiveness of the bayonet tube

- P :

-

Pressure (Pa)

- Q T :

-

Rate of total heat transmission (W)

- F :

-

Friction factor

- Re:

-

Reynolds number

- Q S :

-

Rate of short circuit heat transmission (W)

- w :

-

Water

- m :

-

Mean

- 1 :

-

Inner tube (CPVC, PVC, GI, Cu, Al)

- i :

-

Inner surface/inlet

- o :

-

Outer surface/outlet

- f :

-

Fluid

- 2:

-

Outer or annulus tube (GI tube)

- h :

-

Hydraulic

- r :

-

Radial component

- z :

-

Axial component

- ∆ :

-

Difference

References

Almanza-Huerta L, Hernandez-Guerrero A, Krarti M, Luna JM (2010) Parametric analysis of a bayonet tube with a special type of extended surface. In: ASME international mechanical engineering congress and exposition, pp 781–790

Anitha S, Pichumani M (2022) Numerical analysis on heat transfer performance of industrial double-tube heat exchanger using CNT: Newtonian/non-Newtonian hybrid nanofluids. J Therm Anal Calorim 2022:1–22

Astakhov VP (2012) Environmentally friendly near-dry machining of metals. In: Metalworking fluids (MWFs) for cutting and grinding: fundamentals and recent advances, pp 135–200. https://doi.org/10.1533/9780857095305.135

Bagheri E, Wang B-C, Yang Z (2020) Influence of domain size on direct numerical simulation of turbulent flow in a moderately curved concentric annular pipe. Phys Fluids 32(6):065105

Bai L, Fu J, Pang L, Tao Y, Lin G, Wen D (2020) Experimental study on a dual compensation chamber loop heat pipe with dual bayonet tubes. Appl Therm Eng 180:115821. https://doi.org/10.1016/J.APPLTHERMALENG.2020.115821

Bai W, Chen W, Zeng C, Wu G, Chai X (2022) Thermo-hydraulic performance investigation of heat pipe used annular heat exchanger with densely longitudinal fins. Appl Therm Eng 211:118451. https://doi.org/10.1016/J.APPLTHERMALENG.2022.118451

Bardina JE, Huang PG, Coakley TJ (1997) Turbulence modeling validation, testing, and development. NASA Tech Memorandum 110446(A-976276)

Blazek J (2015) Computational fluid dynamics: principles and applications. Butterworth-Heinemann, London

Boni F (1958) The design of a liquid metal heated bayonet tube steam generator. J Am Soc Naval Eng 70(2):231–244

Cheng X, Tak NI (2006) CFD analysis of thermal–hydraulic behavior of heavy liquid metals in sub-channels. Nucl Eng Des 236(18):1874–1885

Damjanović D, Kozak D, Živić M, Ivandić Ž, Baškarić T (2011) CFD analysis of concept car in order to improve aerodynamics. Járműipari Innováció 1(2):108–115

Gao Q, Zhang P, Peng W, Chen S, Zhao G (2021) Structural design simulation of bayonet heat exchanger for sulfuric acid decomposition. Energies (basel) 14(2):422

Gorensek MB, Summers WA (2009) Hybrid sulfur flowsheets using PEM electrolysis and a bayonet decomposition reactor. Int J Hydrog Energy 34(9):4097–4114. https://doi.org/10.1016/J.IJHYDENE.2008.06.049

Hattori H et al (2022) Experimental study of laminar-to-turbulent transition in pipe flow. Phys Fluids 34(3):034115

Hazmoune M et al (2020) Numerical analysis of a solar tower receiver novel design. Sustainability 12(17):6957

Jahan CS, Quamruzzaman C, Mazumder QH, Haque TA (2004) Artificial ground freezing method for shaft construction in Maddhapara Hardrock Mine, Bangladesh: minimizationofits cost. Biol Sci PJSIR 47(2):112–117

Jolly AJ, O’Doherty T, Bates CJ (1999) COHEX: a computer model for solving the thermal energy exchange in an ultra high temperature heat exchanger. Part B: validation and results. Appl Therm Eng 19(4):389–398. https://doi.org/10.1016/S1359-4311(98)00060-X

Kaneda M, Yu B, Ozoe H, Churchill SW (2003) The characteristics of turbulent flow and convection in concentric circular annuli. Part I: flow. Int J Heat Mass Transf 46(26):5045–5057. https://doi.org/10.1016/S0017-9310(03)00365-X

Kingsley B, Segal BL, Likoff W (1967) Principles of hydrome-chanics: comments on thrombus formation. In: Segal BL, Kilpatrick DG (eds) Engineering in the practice of medicine. Williams & Wilkins, Baltimore, pp 278–289

Li CH (1981) Analytical solution of the heat transfer equation for a bayonet tube heat exchanger. Am Soc Mech Eng 1981:1–9

Li C (1986) Effect of radiation heat transfer on a bayonet tube heat exchanger. AIChE J 32(2):341–343

Liu S, Xia F, Yu D, Mei H, Li T (2023) CFD investigation on thermal hydraulics of the double-wall bayonet tube heat exchanger in CLEAR-S facility. Ann Nucl Energy 182:109595

Lock GSH, Minhas H (1997) Bayonet tube heat exchanger

Lock GSH, Wu M (1993) Heat transfer characteristics of a bayonet tube using air under laminar conditions. Int J Heat Mass Transf 36(2):287–291. https://doi.org/10.1016/0017-9310(93)80004-E

Lundberg RE, McCuen PA, Reynolds WC (1963) Heat transfer in annular passages. Hydrodynamically developed laminar flow with arbitrarily prescribed wall temperatures or heat fluxes. Int J Heat Mass Transf 6(6):495–529. https://doi.org/10.1016/0017-9310(63)90124-8

Mahulikar SP, Herwig H, Zhou J, Sodhani YM (2011) Surface radiative transfer in gas-to-gas cocurrent microheat exchanger. AIChE J 57(1):40–50

Minette F, de Almeida LC, Feinstein J, De Wilde J (2022) Structured ZoneFlow™-Bayonet steam reforming reactor for reduced firing and steam export: pressure drop and heat transfer modelling and evaluation of the reactor performance. Chem Eng J Adv 10:100258

Minhas H, Lock GSH (1995) Transitional forced convection in a bayonet tube. Int Commun Heat Mass Transf 22(5):721–728. https://doi.org/10.1016/0735-1933(95)00058-7

Minhas Harpal, Lock GSH (1997) Forced convection in an air-filled bayonet tube during the laminar-turbulent transition. Int J heat mass transf 40(8):1885–1894. https://doi.org/10.1016/S0017-9310(96)00225-6

Minhas H, Lock GSH, Wu M (1995) Flow characteristics of an air-filled bayonet tube under laminar conditions. Int J Heat Fluid Flow 16(3):186–193. https://doi.org/10.1016/0142-727X(95)97181-Q

Moradi HV, Tavoularis S (2019) Flow instability in weakly eccentric annuli. Phys Fluids 31(4):044104

Pérez-Álvarez R, Rodríguez-Sánchez MR, Acosta-Iborra A, Santana D (2018) Effect of eccentricity on the hydrodynamics and heat transfer of molten salt in bayonet receivers for solar power towers. In: AIP conference proceedings, AIP Publishing LLC, p 080004

Pérez-Álvarez R, Laporte-Azcué M, Acosta-Iborra A, Santana D (2019a) Effect of eccentricity on the thermal stresses in a bayonet tube for solar power tower receivers. In: AIP conference proceedings, AIP Publishing LLC, p 30041

Pérez-Álvarez R, Marugán-Cruz C, Santana-Santana D, Acosta-Iborra A (2019b) Comparison of the heat transfer characteristics of molten salt, liquid sodium and supercritical CO2 in bayonet tubes of solar tower receivers. In: AIP conference proceedings, AIP Publishing LLC, p 80005

Pérez-Álvarez R, Marugán-Cruz C, Santana D, Acosta-Iborra A (2023) Influence of eccentricity on the thermomechanical performance of a bayonet tube of a central solar receiver. Appl Therm Eng 2023:119988

Pimentel E, Papakonstantinou S, Anagnostou G (2012) Numerical interpretation of temperature distributions from three ground freezing applications in urban tunnelling. Tunn Undergr Space Technol 28(1):57–69. https://doi.org/10.1016/J.TUST.2011.09.005

Pradhan AR, Kumar S, Singh H, Singh G, Saptoro A, Kumar P (2022) Flow modelling and energy consumption of a hydrotransportation system possessing variable flow boundaries. Chem Eng Res Des 188:988–1010

Rodríguez-Sánchez MR, Sánchez-González A, Marugán-Cruz C, Santana D (2014) New designs of molten-salt tubular-receiver for solar power tower. Energy Proc 49:504–513. https://doi.org/10.1016/J.EGYPRO.2014.03.054

Ronsse F, Pieters JG, Dewettinck K (2007) Numerical spray model of the fluidized bed coating process. Drying Technol 25(9):1491–1514

Rouabhi A, Tijani M, Stab O, Charnavel Y, You T (2008) A semi-analytical approach for modelling heat transfer during salt-cavern leaching process. Int J Numer Anal Methods Geomech 32(13):1617–1634

Singh N, Sharma RV, Kumar S (2023) Experimental analysis of a bayonet tube at constant wall temperature conditions under laminar, transition, and turbulent flow. ASME J Heat Mass Transf 2023:1–24

Steinhaus H (2016) Wrocław again. In: Mathematician for all seasons. Springer, London, pp 85–283

Swamee PK, Aggarwal N, Aggarwal V (2008) Optimum design of double pipe heat exchanger. Int J Heat Mass Transf 51(9–10):2260–2266. https://doi.org/10.1016/J.IJHEATMASSTRANSFER.2007.10.028

Vafeas P, Bakalis P, Papadopoulos PK (2019) Effect of the magnetic field on the ferrofluid flow in a curved cylindrical annular duct. Phys Fluids 31(11):117105

Vitel M, Rouabhi A, Tijani M, Guérin F (2015) Modeling heat transfer between a freeze pipe and the surrounding ground during artificial ground freezing activities. Comput Geotech 63:99–111. https://doi.org/10.1016/J.COMPGEO.2014.08.004

Vodret S, Di Maio DV, Caruso G (2014) Numerical simulation of turbulent forced convection in liquid metals. J Phys Conf Ser 2014:012033

Wilcox DC (1998) Turbulence modeling for CFD, vol 2. DCW Industries, La Canada

Yang X, Cai Z, Luo T (2020) A special type of tube receiver unit for solar thermal power generation towers. Energy Rep 6:2841–2850

Zheng G, Zhang T, Diao Y (2015) Mechanism and countermeasures of preceding tunnel distortion induced by succeeding EPBS tunnelling in close proximity. Comput Geotech 66:53–65. https://doi.org/10.1016/J.COMPGEO.2015.01.008

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

NS, who also wrote the manuscript, developed the simulation work on the bayonet tube. RVS acted as a research mentor, reviewing the paper and data analysis, while SK meticulously scrutinized the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, N., Sharma, R.V. & Kumar, S. CFD analysis of constant wall-temperature with different materials bayonet tubes in variable flow region. Multiscale and Multidiscip. Model. Exp. and Des. 6, 537–551 (2023). https://doi.org/10.1007/s41939-023-00161-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41939-023-00161-0