Abstract

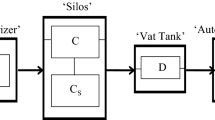

Present paper carried out profit analysis of skimmed milk powder producing system of milk plant which consists of six subsystems—‘Chiller’, ‘Cream Separator’, ‘Skimmed Milk Pasteurizer’, ‘Vacuum Tube’, ‘Evaporators’ and ‘Drying Chamber’. All the six subsystems are connected in series. The subsystems include ‘Chiller’, ‘Cream Separator’, ‘Skimmed Milk Pasteurizer’ and ‘Vacuum Tube’ with each having a single unit. The subsystem ‘Evaporators’ consists of three similar units connected in parallel configuration and present subsystem works with reduced capacity on failure of one evaporator out of three and completely fails as soon as second unit fails out of three units of subsystem ‘Evaporators’. The subsystem ‘Drying Chamber’ having two similar units in which one is operative while other is in cold standby. Fuzzy failure rates and fuzzy repair rates of the subsystems of skimmed milk powder producing system are assumed to follow general distribution. Trapezoidal fuzzy numbers are employed to analyze the performance of skimmed milk powder producing system of milk plant. The numerical results for availability and profit of skimmed milk powder producing system have been evaluated for various choices of system parameters and cost by considering Exponential distribution, Rayleigh distribution and Weibull distribution.

Similar content being viewed by others

References

Aggarwal A, Kumar S, Singh V (2015) Performance modeling of the skim milk powder production system of a dairy plant using RAMD analysis. Int J Qual Reliab Manag 32(2):167–181

Aggarwal AK, Kumar S, Singh V (2016) Mathematical modeling and fuzzy availability analysis of skim milk powder system of a dairy plant: a case study. Int J Syst Assur Eng Manage 7(Suppl. 1):S322–S334

Aggarwal AK, Kumar S, Singh V (2017) Mathematical modeling and fuzzy availability analysis for serial processes in the crystallization system of a sugar plant. J Ind Eng Int 13(1):47–58

Barak MS, Garg R, Kumar A (2021) Reliability measures analysis of a milk plant using RPGT. Life Cycle Reliab Saf Eng. https://doi.org/10.1007/s41872-020-00163-8

Chen S, Chen J (2009) Fuzzy risk analysis based on ranking generalized fuzzy numbers with different heights and different spreads. Expert Syst Appl 36(3):6833–6842

Chen S, Munif A, Chen G, Liu H, Kuo B (2012) Fuzzy risk analysis based on ranking generalized fuzzy numbers with different left heights and right heights. Expert Syst Appl 39(7):6320–6334

Gupta P, Lal AK, Sharma RK, Singh J (2005) Numerical analysis of reliability and availability of the serial processes in butter-oil processing plant. Int J Qual Reliab Manag 22(3):303–316

Kajal S, Tewari PC (2012) Performance optimization for skim milk powder unit of a dairy plant using genetic algorithm. Int J Eng 25(3):211–221

Kumar J, Goel M (2017) Fuzzy reliability analysis of a pulping system in paper industry with general distributions for all random variables. Cogent Math 4:1–14

Kumar V, Modgil V (2014) Availability optimization of ice cream making unit of milk plant using genetic algorithm. Int J Manag Bus Stud 4(3):17–20

Kumar K, Singh J, Kumar P (2009) Fuzzy reliability and fuzzy availability of the serial-Process in butter-oil processing plant. J Math Stat 5(1):65–71

Kumari P, Kadyan MS, Kumar J (2019) Profit analysis of butter-oil (ghee) producing system of milk plant using supplementary variable technique. Int J Syst Assur Eng Manag 10(6):1627–1638

Acknowledgements

The authors are thankful to the reviewers for their valuable suggestions/comments that led to an improved presentation of this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumari, P., Kadyan, M.S. & Kumar, J. Profit analysis of skimmed milk powder producing system of milk plant using trapezoidal fuzzy numbers with different left and right heights. Life Cycle Reliab Saf Eng 10, 387–401 (2021). https://doi.org/10.1007/s41872-021-00172-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41872-021-00172-1