Abstract

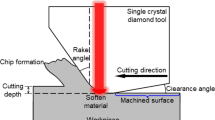

In this study, surface modification of monocrystalline silicon with two doses of hydrogen ion implantation and the plunge cutting process were conducted to explore the influence of hydrogen ions on the cutting behavior of silicon. The results show that ion implantation is capable of deteriorating or improving the machinability of silicon, depending on the implantation dose. More cleavages and a reduction of critical depth of cut (CDoC) were observed for the silicon with a low implantation dose in the cutting direction of < 100> in comparison to bare silicon, while no cleavage and an increase of CDoC were achieved after implantation with a high dose in the same cutting direction. Besides, the ductile cutting and thrust forces of the silicon with the low dose are larger than the bare silicon, but the forces are significantly reduced for the silicon after the high dose of implantation. The variation of the cutting forces is due to the different required stresses to overcome ductile and fracture deformation of silicon.

Similar content being viewed by others

References

Fang F, Wu H, Zhou W, Hu X (2007) A study on mechanism of nano-cutting single-crystal silicon. J Mater Process Technol 184:407–410

Liu K, Wang H, Zhang XQ (2020) Ductile mode cutting of brittle materials. Springer, Berlin

Goel S, Luo X, Agrawal A, Reuben RL (2015) Diamond machining of silicon: a review of advances in molecular dynamics simulation. Int J Mach Tools Manuf 88:131–164

Leung T, Lee W, Lu X (1998) Diamond turning of silicon substrates in ductile-regime. J Mater Process Technol 73:42–48

Arif M, Rahman M, San WY (2012) A state-of-the-art review of ductile cutting of silicon wafers for semiconductor and microelectronics industries. Int J Adv Manuf Technol 63:481–504

Choong Z, Huo D, Degenaar P, O’Neill A (2019) Micro-machinability and edge chipping mechanism studies on diamond micro-milling of monocrystalline silicon. J Manuf Process 38:93–103

Lee YJ, Wang H (2020) Current understanding of surface effects in microcutting. Mater Des 192:108688

Wang J, Yang Y, Zhu Z, Wang Y, Liao W, Guo P (2020) On ductile-regime elliptical vibration cutting of silicon with identifying the lower bound of practical nominal cutting velocity. J Mater Process Technol 283:116720

Yan J, Asami T, Harada H, Kuriyagawa T (2012) Crystallographic effect on subsurface damage formation in silicon microcutting. CIRP Ann 61:131–134

Wang Z, Chen J, Wang G, Bai Q, Liang Y (2017) Anisotropy of single-crystal silicon in nanometric cutting. Nanoscale Res Lett 12:300

Xiao G, To S, Jelenković E (2015) Effects of non-amorphizing hydrogen ion implantation on anisotropy in micro cutting of silicon. J Mater Process Technol 225:439–450

Mukaida M, Yan J (2017) Ductile machining of single-crystal silicon for microlens arrays by ultraprecision diamond turning using a slow tool servo. Int J Mach Tools Manuf 115:2–14

Zhao Z, To S, Xiao G, Jelenković E (2019) Effects of cutting angles on deformation of single-crystal silicon in plunge cutting along <1 0 0> direction. Mater Lett 253:234–237

Fang F, Chen Y, Zhang X, Hu X, Zhang G (2011) Nanometric cutting of single-crystal silicon surfaces modified by ion implantation. CIRP Ann 60:527–530

Tanaka H, Shimada S (2013) Damage-free machining of monocrystalline silicon carbide. CIRP Ann 62:55–58

Wang J, Fang F, Zhang X (2015) An experimental study of cutting performance on monocrystalline germanium after ion implantation. Precis Eng 39:220–223

Wang J, Zhang X, Fang F, Chen R (2019) Diamond cutting of micro-structure array on brittle material assisted by multi-ion implantation. Int J Mach Tools Manuf 137:58–66

To S, Jelenković EV, Goncharova LV, Wong SF (2018) Mechanical characteristics of hydrogen-implanted crystalline silicon after post-implantation annealing. Vacuum 152:40–46

To S, Wang H, Jelenković E (2013) Enhancement of the machinability of silicon by hydrogen ion implantation for ultra-precision micro-cutting. Int J Mach Tools Manuf 74:50–55

Pérez R, Gumbsch P (2000) Directional anisotropy in the cleavage fracture of silicon. Phys Rev Lett 84:5347

Ovsyannikov SV, Shchennikov VV Jr, Shchennikov VV, Ponosov YS, Antonova IV, Smirnov SV (2008) Raman characterization of hydrogen ion implanted silicon: “High-dose effect”? Phys B Condens Matter 403:3424–3428

Yan J (2004) Laser micro-Raman spectroscopy of single-point diamond machined silicon substrates. J Appl Phys 95:2094–2101

Xu Z, He Z, Song Y, Fu X, Rommel M, Luo X, Hartmaier A, Zhang J, Fang F (2018) Topic review: application of Raman spectroscopy characterization in micro/nano-machining. Micromachines 9:361

Yan J, Asami T, Harada H, Kuriyagawa T (2009) Fundamental investigation of subsurface damage in single-crystalline silicon caused by diamond machining. Precis Eng 33:378–386

Henttinen K, Suni I, Lau S (2000) Mechanically induced Si layer transfer in hydrogen-implanted Si wafers. Appl Phys Lett 76:2370–2372

Di Z, Wang Y, Nastasi M, Shao L, Lee J-K, Theodore N (2008) Evidence for ion irradiation induced dissociation and reconstruction of Si–H bonds in hydrogen-implanted silicon. Appl Phys Lett 93:104103

Acknowledgements

The work described in this paper was jointly supported by the Research Committee (Project No. G-YBLE) and State Key Laboratory of Ultra-precision Machining Technology (Project No. RUWB) of the Hong Kong Polytechnic University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there are no conflicts of interest to disclose.

Rights and permissions

About this article

Cite this article

Zhao, Z., Jelenković, E.V., Xiao, G. et al. Hydrogen Ion Implantation Induced Cutting Behavior Variation in Plunge Cutting of the Monocrystalline Silicon. Nanomanuf Metrol 4, 209–215 (2021). https://doi.org/10.1007/s41871-020-00086-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41871-020-00086-z