Abstract

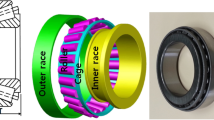

The major objective of this research is to estimate the effects of temperature on tapered roller bearings through the investigation of strain and thermal behaviors. Autodesk Fusion 360 is chosen to design the geometry in the manner specified and employing ANSYS Workbench to perform Finite Element Analysis. The stresses between the roller, interior, and exterior rings can be evaluated by bearing studies. This study focuses on thermal and static analysis to determine the temperature at various bearing locations and to simulate the bearing's condition to anticipate its condition. From our computational analysis of coupled finite element analysis for range of temperatures between 150 and 190 °C we observe inner racer temperature is higher than outer racer. At 190 °C inner racer and outer racer values obtained are 181.06 °C and 165.88 °C respectively. The outcome provides a clear picture of the temperature distribution on the bearing in relation to the stress and strain from structural analysis. Equivalent wavelength shift is calculated using the ANSYS result. GratingMOD optical tool is used to design and simulate Fibre Bragg Grating (FBG) sensors.

Similar content being viewed by others

Data availability

Not applicable.

References

Tarawneh C, Fuentes A, Kypuros J, Navarro L, Vaipan A, Wilson B (2012) Thermal modeling of a railroad tapered-roller bearing using finite element analysis. J Thermal Sci Eng Appl 4:031002. https://doi.org/10.1115/1.4006273

Kumaran SS, Velmurugan P, Tilahun S (2020) Effect on stress and thermal analysis of tapered roller bearings. J Crit Rev 7:1–10. https://doi.org/10.31838/jcr.07.09.99

Rehman S, Kumar NMKS, Abrar S (2016) Structural and thermal analysis on the tapered-roller bearing. SSRG Int J Mech Eng 3(7):5–12. https://doi.org/10.14445/23488360/IJME-V3I7P102

Mishra S, Sharan P, Saara K (2022) Compactness measure of rail wheel rolling contact of the freight wagon. Int J Inf Tecnol 14:2335–2342. https://doi.org/10.1007/s41870-022-00977-y

Atan E (2005) On the prediction of the design criteria for modification of contact stresses due to thermal stresses in the gear mesh. Tribol Int 38(3):227–233

Guta S, Tilahun D (2016) Stress analysis of rail joint under wheel load. Int J Innovative Sci Eng Technol 3(6):526–543

Jagadeep B, Kiran Kumar P, Subbaiah KV (2018) Stress analysis on rail wheel contact. Int J Res Eng 1:47–52

Hirani H (2009) Root cause failure analysis of outer ring fracture of four-row cylindrical roller bearing. J Tribol Trans 52(2):180–190

Muro H, Tssushima N, Numome K (1973) Failure analysis of rolling bearings by X-ray measurement of residual stress. Wear 25(3):345–356

Moundekar ND, Deshmukh BD (2014) Study of failure modes of rolling bearings, international open access. J Modern Eng Res 4(1):139–145

Overstam H (2006) The influence of bearing geometry on the residual stress state in cold drawn wire analyzed by the FEM. J Mater Process Technol 171(3):446–450

Vernersson T (2007) Temperatures at railway tread braking. Part 1: modeling. Proc Inst Mech Eng F J Rail Rapid Transit 221(2):167–182

Dunnuck DL (1992) Steady-state temperature and stack-up force distributions in a railroad roller bearing assembly. MS thesis, University of Illinois at Urbana-Champaign, Urbana, IL

Wang H (1996) Axle burn-off and stack-up force analyses of a railroad roller bearing using the finite element method. PhD thesis, University of Illinois at Urbana-Champaign, Urbana, IL

Cole KD, Tarawneh CM, Wilson BM (2009) Analysis of FluxBase fins for estimation of heat transfer coefficient. Int J Heat Mass Transf 52:92–99

Du C, Dutta S, Kurup P, Yu T, Wang X (2019) A review of railway infrastructure monitoring using fiber optic sensors. Sensors Actuators A Phys. https://doi.org/10.1016/j.sna.2019.111728

Deepa N, Sharma S, Gayathri HN, Sharan P, Rakesh BR, Bhat AG (2023) FEM analysis of railway brake disc for safety of train. In: 2023 10th international conference on computing for sustainable global development (INDIACom), New Delhi, India, pp 316–320

Xu J, Zhang J, Huang Z, Wang L (2015) Calculation and finite element analysis of the temperature field for high-speed rail bearing based on vibrational characteristics. J Vibroeng 17(2):720–732

Xu J, Zhang J, Huang Z, Wang L (2015) Calculation and finite element analysis of the temperature field for high-speed rail bearing based on vibrational characteristics. J Vibroeng 17:720–732

Deepa N, Sharan P, Shwetha K, Meshram V (2022) Design of temperature monitoring for wheel using optical sensor in railway safety system. In: 2022 9th international conference on computing for sustainable global development (INDIACom), pp 93–98. https://doi.org/10.23919/INDIACom54597.2022.9763117

Thammaiah NS, Patil PP, Upadhyaya AM, Sharan P, Srivastava MC (2020) Nonlinear response of fiber Bragg grating for health monitoring of railway track. In: 2020 7th international conference on computing for sustainable global development (INDIACom), pp 144–149. https://doi.org/10.23919/INDIACom49435.2020.9083699

Sharan P, Patil PP, Srivastava MC, Upadhyaya AM (2020) Nonlinear response of fiber Bragg grating for health monitoring of railway track. IEEE, New Delhi, pp 3–7

Mishra S, Sharan P, Kamath SP, Saara K (2021) Monitoring of rail wheel impact for various train speeds. In: Proc. 2021 8th Int. Conf. Comput. Sustain. Glob. Dev. INDIACom 2021, pp 714–719. https://doi.org/10.1109/INDIACom51348.2021.00127

Choudakkanavar G, Mangai JA, Bansal M (2022) MFCC based ensemble learning method for multiple fault diagnosis of roller bearing. Int J Inf Tecnol 14:2741–2751. https://doi.org/10.1007/s41870-022-00932-x

Sharan P, Sandhya KV, Barya R et al (2021) Design and analysis of moems based displacement sensor for detection of muscle activity in human body. Int J Inf Tecnol 13:397–402. https://doi.org/10.1007/s41870-020-00533-6

Sharma R et al (2009) Design & simulation of optical fiber Bragg grating pressure sensor for minimum. J Theor Appl Inf Technol 2009:515–530

Acknowledgements

In order to conduct research, the authors would like to thank AICTE RPS funded project 8-109/FDC/RPS(POLICY-1)/2019-2020 and Dr. Preeta Sharan Dean R&D Oxford College of Engineering in Bengaluru for providing lab facility, the essential technology, and assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deepa, N., Sharan, P. & Sharma, S. Computer-aided analysis of tapered roller bearings for rail transport system. Int. j. inf. tecnol. 16, 831–839 (2024). https://doi.org/10.1007/s41870-023-01645-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41870-023-01645-5