Abstract

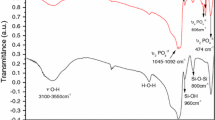

The effect of HA amount on the physical properties and bioactivity of porous HA prepared by replica method using Musa paradisiaca as template has been studied. The templates were prepared by cutting the banana fronds into cylindrical shape. Slurries were prepared by mixing 9, 10, and 11 g HA with 11% sago starch, 2.5% Darvan821A, and distilled water. Slurries then stirred at 150 rpm for 24 h. Templates were impregnated into slurry and then dried at 110°C for 2 h. The green bodies were burned at 600°C for 1 h followed by sintering at 1250°C for 1 h. Porous HA was tested in vitro using simulated body fluid solution by soaking for 7–14 days. The cell attachment done by using Baby Hamster Kidney (BHK21) cell. The porous HA was produced with shrinkage in the range of 53.6–58.9%vol, density of 1.26–1.47 g/cm3, porosity of 53.5–60.1%, and compressive strength of 3.89–4 MPa. The pore size was obtained at the range 71.26–89.13 μm. The biodegradation rate of samples was found at the range of 1.34–2.27% with the increased apatite and carbonate content on porous HA after immersion proven by FTIR result. The cell attachment test showed that the viability of HA was 80.3% confirming that samples were non-toxic material.

Similar content being viewed by others

References

Thirumalai, J. Introductory chapter: The testament of hydroxyapatite: new prospect in regenerative medicinal treatments. In Hydroxyapatite: advances in composite nanomaterials, biomedical applications and its technological facets; BoD–Books on Demand. 3–14 (2018)

Qi, C., Zhu, Y.J., Lu, B.Q., Zhao, X.Y., Zhao, J., Chen, F.: J. Mater. Chem. 2012(22), 22642–2650 (2012)

Zhang, Y., Kong, D., Yokogawa, Y., Feng, X., Tao, Y., Qiu, T.: J. Am. Ceram. Soc. 95(1), 147–152 (2012)

Maheshwari, S.U., Samuel, V.K., Nagiah, N.: Ceram. Int. 40, 8469–8477 (2014)

Studart, A.R., Gonzenbach, U.T., Tervoort, E., Gauckler, L.J.: J. Am. Ceram. Soc. 89(6), 1771–1789 (2006)

Ahmed, Y.M.Z., Ewais, E.M.M., El-Seikh, S.M.J.: Asian Ceram. Soc. 3, 108–115 (2015)

Sopyan, I., Fadli, A., Mel, M.: J. Mech. Behav. Biomed. Mater. 8, 86–98 (2012)

Sopyan, I., Kaur, J.: Ceram. Int. 35, 3161–3168 (2009)

Min, S.-H., Jin, H.-H., Park, H.-Y., Park, I.-M., Park, H.-C., Yoon, S.-Y.: Mater. Sci. For. 2006(510–511), 754–757 (2006)

Fadli, A., Widiyanti, P., Noviana, D., Prabowo, A., Ismawati, H.: J. Rek. Kim. Ling. 15(2), 62–70 (2020)

Sharma, K., Dixit, A., Singh, S., Bhattacharya, S., Prajapat, C.L., Sharma, P.K., Yusuf, S.M., Tyagi, A.K., Kothiyal, G.P.: Mater. Sci. Eng. C 29(7), 2226–2233 (2009)

Kokubo, T., Kushitani, H., Sakka, S., Kitsugi, T., Yamamuro, T.: J. Biomed. Mater. Res. 1990(24), 721–734 (1990)

Swain, S.K., Bhattacharyya, S., Sarkar, D.: Mater. Sci. Eng. C 31, 1240–1244 (2011)

Fadli, A.; Komalasari, K.; Huda, F.; Ardi, T.; Habib, I. J. Nat. Fiber. (2020)https://doi.org/10.1080/15440478.2020.1848698

Kokubo, T., Takadama, H.: Biomaterial. 12(2), 155–163 (2006)

Li, S., Huang, B., Chen, Y., Gao, H., Fan, Q., Zhao, J., Su, W.: Int. J. Sur. 11(6), 477–482 (2013)

Kang, S.J.L.: Sintering, densification, grain growth & microstructure. Elsevier Butterworth-Heinemann, Burlington, UK (2005)

Kamal, M.M., Baini, R., Mohamaddan, S., Selaman, O.S., Zauzi, N.A., Rahman, M.R., ... Othman, A.K.: Effect of temperature to the properties of sago starch. In IOP Conf. Ser.: Mat, Sci. and Eng. 206(1), 012–039 (2017)

Yubao, L., Klein, C.P.A.T., Xindong, Z., DeGroot, K.: Biomaterials 14, 969–972 (1993)

Fadli, A.; Komalasari. Metode pembuatan komposit berpori menggunakan cara protein foaming-starch consolidation. Indonesia Patent. 2013; P00201304608.

Rodríguez‐Lorenzo, L.M., Vallet‐Regí, M., Ferreira J.M.F.: Fabrication of porous hydroxyapatite bodies by a new direct consolidation method: starch consolidation. J. Biomed. Mater. Res. 60(2), 232–240 (2002)

Kang, S.J.L.: Sintering: densification, grain growth and microstructure. Elsevier. Ch. 4–5, 37–77 (2004)

Jamaludin, A.R., Kasim, S.R., Ismail, A.K., Abdullah, M.Z., Ahmad, Z.A.: J. Eur. Ceram. Soc. 35, 1905–9190 (2015)

Garrido, L.B., Albano, M.P., Genova, L.A., Plucknett, K.P.: J. Mater. Res. 13(1), 39–45 (2008)

Gibson, L.J., Ashby, M.F.: Cellular solids structure and properties. Pergamon Press, Oxford (1988)

Al-khazraji, K.K., Hanna, W.A., Ahmed, P.S.: Eng. Tech. J. 28(10), 1880–1892 (2010)

Wang, C.X., Zhou, X., Wang, M.: Biomed. Mater. Eng. 14, 5–11 (2014)

Wen, H.B., de Wijin, J.R., Cui, F.Z., de Groot, K.: J. Biomed. Mater. Res. 41, 227–236 (1998)

Takadama, H., Hashimoto, M., Mizuno, M., Kokubo, T.: Round-robin test of SBF for in vitro measurement of apatite-forming ability of synthetic materials. Phosphorus Res Bull. 17, 119–125 (2004)

ISO10993-5. International Standard : Biological evaluation of medical devices-Part 5 Tests for in vitro cytotoxicity (2009)

Kantharia, N., Naik, S., Apte, S., Kheur, M., Kheur, S., Kale, B.J.: Dent. Res. Sci Dev. 1, 15–19 (2014)

Murphy, C.M., Haugh, M.G., Brien, F.J.O.: Biomaterials. 31(3), 461–466 (2010)

Acknowledgements

The authors are grateful for the financial support from Ministry of Research Technology and Higher Education of Indonesia for the financing of this research (no. 21/INS-2/PPKE4/2019).

The authors declare no competing interests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fadli, A., Widiyanti, P., Noviana, D. et al. Porous hydroxyapatite scaffold produced using Musa paradisiaca template and its in vitro bioactivity. J Aust Ceram Soc 58, 357–366 (2022). https://doi.org/10.1007/s41779-021-00677-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-021-00677-z