Abstract

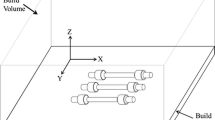

This study investigated the influences of the particle size distribution (characterized by the amounts of fines and coarses and by the maximum particle size (1|3 mm)) and the compaction pressure (50|100 MPa) of die-pressed bars on the behavior of the bulk density, cold modulus of rupture (CMOR) and Young’s modulus E during five thermal shocks (TS). Highest densities were obtained for wide particle size distributions with densest packed coarse aggregates, a slight excess of lubricating fines and a high compaction pressure. Highest CMOR and E were obtained for the same parameters with the exception of a maximum particle size of 1 mm inducing lower flaw sizes. Independent on the compaction pressure, lowest CMOR losses during TS were obtained for a wide particle size distribution with a high number of aggregates constituted of medium-sized grains and densest packed coarses. Supposedly, crack deflection and contact shielding toughening occurred. During TS, E behaved differently. Probably, E was low when there were many flaws. During TS, these led to a large process zone and high decrease of E whereas for batches with higher initial E a crack could propagate with less microstructural interactions giving supposedly a smaller process zone and a reduced decrease.

Similar content being viewed by others

Availability of data and material

All data was included in the Online Resource by means and standard deviations.

References

Ratle, A., Pandolfelli, V.C., Allaire, C., Rigaud, M.: Correlation between thermal shock and mechanical impact resistance of refractories. Br. Ceram. Trans. 96(6), 225–230 (1997)

Hasselman, D.P.H.: Elastic energy at fracture and surface energy as design criteria for thermal shock. J. Am. Cer. Soc. 46(11), 535–540 (1963)

Hasselman, D.P.H.: Unified theory of thermal shock fracture initiation and crack propagation in brittle ceramics. J. Am. Cer. Soc. 52(11), 600–604 (1969)

Larson, D.R., Coppola, J.A., Hasselman, D.P.H.: Fracture toughness and spalling behavior of high-Al2O3 refractories. J. Am. Cer. Soc. 57(10), 417–421 (1974)

Kingery, W.D.: Factors affecting thermal stress resistance of ceramic materials. J. Am. Cer. Soc. 38(1), 3–15 (1955)

Ko, Y.-C.: Influence of the total ffine content on the thermal shock damage resistance of Al2O3-spinel castables. Ceram. Int. 27, 501–507 (2001)

Schulle, W.: Refractory materials (in German). Dt. Verlag für Grundstoffind. Leipzig, Erste edition (1990)

Luo, Y., Gu, H., Zhang, M., Huang, A., Li, H., Yu, C., Li, T., Yan, P.: Research on thermal shock resistance of porous refractory material by strain-life fatigure approach. Ceram Int. 46, 14884–93 (2020)

Ulbricht, J., Dudczig, S., Tomsu, F., Palco, S.: Technological measures to improve the thermal shock resistance of refractory materials. Interceram 2, 103–106 (2012)

Fu, L., Gu, H., Huang, A., Zhang, M., Hong, X., Jin, L.: Possible improvements of alumina-magnesia castable by lightweight microporous aggregates. Ceram Int. 41, 1263–70 (2015)

Fruhstorfer, J., Möhmel, S., Thalheim, M., Schmidt, G., Aneziris, C.G.: Microstructure and strength of fused high alumina materials with 2.5,wt% zirconia and 2.5,wt% titania additions for refractory applications. Ceram. Int. 41, 10644–10653 (2015)

Lee, W.E., Zhang, S., Karakus, M.: Refractories: Controlled microstructure composites for extreme environments. J. Mat. Sci. 39, 6675–6685 (2004)

Luchini, B., Sciti, V.F., Angelico, R.A., Canto, R.B., Pandolfelli, V.C.: Thermal expansion mismatch inter-inclsion cracrack in ceramic systems. Ceram. Int. 42, 12512–15 (2016)

Fruhstorfer, J., Demuth, C., Goetze, P., Aneziris, C.G., Ray, S., Gross, U., Trimis, D.: How the coarse fraction influences the microstructure and the effective thermal conductivity of alumina castables—an experimental and numerical study. J. Eur. Ceram. Soc. 38, 303–12 (2018)

Ulbricht, J., Burkhardt, K.: Über den Körnungsaufbau grobkeramischer feuerfester Werkstoffe (On the grading of coarse ceramic refractory materials). Ceramic Forum International 76(4), D9–12 (1999)

Fruhstorfer, J., Aneziris, C.G.: The influence of the coarse fraction on the porosity of refractory castables. J. Ceram. Sci. Tech. 5(2), 155–166 (2014)

Fruhstorfer, J.: Continuous gap-graded particle packing designs. Mater. Today Commun., 20(100550) (2019)

Fruhstorfer, J., Hubálková, J., Aneziris, C.G.: Particle packings minimizing density gradients of coarse-grained compacts. J. Eur. Ceram. Soc. 39(10), 3264 – 3276 (2019)

Li, Y., Li, X., Zhu, B., Chen, P.: The relationship between the pore size distribution and the thermo-mechanical properties of high alumina refractory castables. Int. J. Mater. Res. 107(3), 263–8 (2016)

Schafföner, S., Fruhstorfer, J., Faßauer, C., Freitag, L., Jahn, C., Aneziris, C.G.: Influence of in situ phase formation on properties of calcium zirconate refractories. J. Eur. Ceram. Soc. 37, 305–13 (2017)

Schafföner, S., Bach, M., Jahn, C., Freitag, L., Aneziris, C.G.: Advanced refractories for titanium metallurgy based on calcium zirconate with improved thermomechanical properties. J. Eur. Ceram Soc. 39, 4394–403 (2019)

Saharan, V.A., Kukkar, V., Kataria, M., Kharb, V., Choudhury, P.K.: Ordered mixing: mechanism, process and applications in pharmaceutical formulations. Asian J. Pharm. Sci. 3(6), 240–259 (2008)

Schulle, W., Burkhardt, K., Tomsu, F.: Evaluation of the modulus of elasticity of refractories. In: UNITECR’99. Proc. Unified Int. Tech. Conf. on Refractories, pp. 410–412 (1999)

Coble, R.L., Kingery, W.D.: Effect of porosity on physical properties of sintered alumina. J. Am. Cer Soc. 39(11), 377–385 (1956)

Montgomery, D.C.: Design and Analysis of Experiments, 5th edn. Wiley, Hoboken (2001)

Benesty, J., Chen, J., Huang, Y., Cohen, I.: Pearson correlation coefficient. In: Noise Reduction in Speech Processing, pp 1–4. Springer (2009)

Development Core Team, R: R: A language and environment for statistical computing. R Foundation for Statistical Computing. Vienna, Austria (2010)

Krause, E., Berger, I., Kröckel, O., Maier, P.: Thermische Prozesse (Thermal Processes), volume 3 of Technologie der Keramik (Ceramic Technology). VEB Verlag für Bauwesen, Berlin (1985)

Fruhstorfer, J., Schafföner, S., Werner, J., Wetzig, T., Schöttler, L., Aneziris, C.G.: Thermal shock performance of refractories for application in steel ingot casting. J. Ceram. Sci Tech. 7(2), 173–181 (2016)

German, R.M.: Sintering Theory and Practice, 1st edn. Wiley, Hoboken (1996)

Bradt, R.C.: Elastic moduli, strength and fracture characteristics of refractories. Key Eng. Mater. 88, 165–92 (1993)

Evans, A.G., Faber, K.T.: Crack-growth resistance of microcracking brittle materials. J. Am. Ceram Soc. 67(4), 255–60 (1984)

Schafföner, S., Fruhstorfer, J., Ludwig, S., Aneziris, C.G.: Cyclic cold isostatic pressing and improved particle packing of coarse grained oxide ceramics for refractory applications. Ceram. Int. 44(8), 9027–36 (2018)

Schafföner, S., Dietze, C., Möhmel, S., Fruhstorfer, J., Aneziris, C.G.: Refractories containing fused and sintered alumina aggregates: Investigations on processing, particle size distribution and particle morphology. Ceram. Int. 43(5), 4252–62 (2017)

Author information

Authors and Affiliations

Contributions

The experiments, analyses and the writing of the article were conducted by the sole author.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The experiments were conducted within the author’s PhD thesis at the Professorship of Ceramics, TU Bergakademie Freiberg, Germany.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Fruhstorfer, J. Influence of the particle size distribution of coarse-grained refractories on the thermal shock performance. J Aust Ceram Soc 57, 899–909 (2021). https://doi.org/10.1007/s41779-021-00593-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-021-00593-2