Abstract

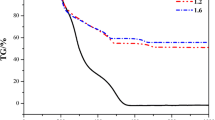

The foaming and foam stabilization mechanisms of potassium laurate (PL), potassium oleate (PO), sodium dodecyl sulfate (SDS), and sodium dodecylbenzenesulfonate (SDBS) were investigated in this study. Magnesia porous ceramics were fabricated by a foaming method, and the sample microstructures were analyzed by scanning electron microscopy (SEM) following heat treatment. Results showed that the foaming ability of the surfactants decreased in the order PO > SDS > SDBS > PL. The addition of calcium stearate (CS), a foam-stabilizing agent, extended the half-lives of SDS, SDBS, and PO foams in the order SDBS > PO > SDS. However, the addition of CS to PL significantly decreased its foam half-life. Pore sizes of the heat-treated samples decreased in the order PL > SDS > SDBS > PO, while the evenness of the pore distribution decreased in the order PO > SDBS > SDS > PL. Porous ceramics prepared with PO and CS had the smallest and most evenly distributed pores in the range of 5–10 μm.

Similar content being viewed by others

References

Dzyuzer, V.Y., Shvydkii, V.S.: Thermal insulation of the refractory masonry in glassmaking furnaces. Glas. Ceram. 71(9–10), 365–368 (2015)

Biswas, P., Rajeswari, K., Mahendar, V., Johnson, R.: Extrusion processing of dense MgAl2O4 spinel honeycombs with low relative density. Ceram. Int. 39(8), 9819–9821 (2013)

Yan, W., Li, N., Han, B.: Influence of microsilica content on the slag resistance of castables containing porous corundum-spinel aggregates. Int. J. Appl. Ceram. Technol. 5(6), 633–640 (2008)

Ji, R., Zhang, Z., Liu, L., Wang, X.: Development of the random simulation model for estimating the effective thermal conductivity of insulation materials. Build. Environ. 80, 221–227 (2014)

Yan, W., Chen, J., Li, N., Qiu, W., Wei, Y., Han, B.: Preparation and characterization of porous MgO-Al2O3 refractory aggregates using an in-situ decomposition pore-forming technique. Ceram. Int. 41(1), 515–520 (2015)

Deng, Z.-Y., Fukasawa, T., Ando, M., Zhang, G.-J., Ohji, T.: Microstructure and mechanical properties of porous alumina ceramics fabricated by the decomposition of aluminum hydroxide. J. Am. Ceram. Soc. 84(11), 2638–2644 (2001)

Vijayan, S., Narasimman, R., Prabhakaran, K.: Effect of emulsion composition on gel strength and porosity in the preparation of macroporous alumina ceramics by freeze gelcasting. J. Asian. Ceram. Soc. 3(3), 279–286 (2015)

Yang, F., Li, C., Lin, Y., Wang, C.-A.: Effects of sintering temperature on properties of porous mullite/corundum ceramics. Mater. Lett. 73, 36–39 (2012)

Sutcu, M., Akkurt, S., Bayram, A., Uluca, U.: Production of anorthite refractory insulating firebrick from mixtures of clay and recycled paper waste with sawdust addition. Ceram. Int. 38(2), 1033–1041 (2012)

Li, M., Luo, X., Zhang, G., Xie, Z., Zhao, L., Jin, H.: Effect of blowing-agent addition on the structure and properties of magnesia porous material. Refract. Ind. Ceram. 58(1), 60–64 (2017)

Lin, X., Yan, W., Ma, S., Chen, Q., Li, N., Han, B., Wei, Y.: Corrosion and adherence properties of cement clinker on porous periclase-spinel refractory aggregates with varying spinel content. Ceram. Int. 43(6), 4984–4991 (2017)

Ma, S., Yan, W., Lin, X., Wu, G., Chen, Z., Li, N.: Corrosion mechanism of ladle slag to lightweight periclase–MA spinel refractories. J. Chin. Ceram. Soc. 46(3), 443–448 (2018)

Harabi, A., Zenikheri, F., Boudaira, B., Bouzerara, F., Guechi, A., Foughali, L.: A new and economic approach to fabricate resistant porous membrane supports using kaolin and CaCO3. J. Eur. Ceram. Soc. 34(5), 1329–1340 (2014)

Li, A., Zhang, H., Yang, H.: Evaluation of aluminum dross as raw material for high-alumina refractory. Ceram. Int. 40(8), 12585–12590 (2014)

Yin, H., Xin, Y., Dang, J., Gao, K., Tang, Y., Yuan, H.: Preparation and properties of lightweight corundum-spinel refractory with density gradient. Ceram. Int. (2018)

Schneider, H., Schreuer, J., Hildmann, B.: Structure and properties of mullite – a review. J. Eur. Ceram. Soc. 28(2), 329–344 (2008)

Pabst, W., Gregorová, E.: Conductivity of porous materials with spheroidal pores. J. Eur. Ceram. Soc. 34(11), 2757–2766 (2014)

Pabst, W., Gregorová, E.: A cross-property relation between the tensile modulus and the thermal conductivity of porous materials. Ceram. Int. 33(1), 9–12 (2007)

Ngo, N.D., Tamma, K.K.: Computational developments for simulation based design:multi-scale physics and flow/thermal/cure/stress modeling analysis, and validation for advanced manufacturing of composites with complex microstructures. Archiv. Comput. Methods Eng. 10(1–2), 201–206 (2003)

Zhang, L., Zhou, D., Chen, Y., Liang, B., Zhou, J.: Preparation of high open porosity ceramic foams via direct foaming molded and dried at room temperature. J. Eur. Ceram. Soc. 34(10), 2443–2452 (2014)

Ahmad, R., Ha, J.H., Song, I.H.: Particle-stabilized ultra-low density zirconia toughened alumina foams. J. Eur. Ceram. Soc. 33, 2559–2564 (2013)

Gonzenbach, U.T., Studart, A.R., Steinlin, D., Tervoort, E., Gauckler, L.J.: Processing of particle-stabilized wet foams into porous ceramics. J. Am. Ceram. Soc. 90, 3407–3414 (2007)

Gonzenbach, U.T., Studart, A.R., Tervoort, E., Gauckler, L.J.: Macroporous ceramics from particle-stabilized wet foams. J. Am. Ceram. Soc. 90, 16–22 (2007)

Zhu, M., Ji, R., Li, Z., Wang, H., Liu, L., Zhang, Z.: Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass. Constr. Build. Mater. 112, 398–405 (2016)

Zhao, J., Shimai, S., Zhou, G., Zhang, J., Wang, S.: Ceramic foams shaped by oppositely charged dispersant and surfactant. Colloids Surf. A Physicochem. Eng. Asp. 537, 210–216 (2018)

González-Corrochano, B., Alonso-Azcárate, J., Rodas, M.: Production of lightweight aggregates from mining and industrial wastes. J. Environ. Manag. 90(8), 2801–2812 (2009)

Jiang, C., Huang, S., Li, J., Zhang, X., Cheng, X.: Formation of closed-pore foam ceramic from granite scraps. Ceram. Int. 44(3), 3469–3471 (2018)

Park, J., Han, Y., Kim, H.: Pore characteristics of Ca(OH)2 foams: impact of surfactant–mineral interaction. J. Mater. Chem. Phys. 124(1), 510–515 (2010)

Funding

This study was funded by the National Key R&D Program of China (2017YFB0310701).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, J., Li, G., Gao, H. et al. Foaming mechanisms of different foaming agents and their effects on the microstructures of porous magnesia ceramics. J Aust Ceram Soc 56, 1005–1011 (2020). https://doi.org/10.1007/s41779-019-00443-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-019-00443-2