Abstract

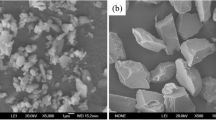

Porous aluminum phosphate (AlPO4) ceramics was fabricated from various powders synthesized at 800 °C, 900 °C, 1000 °C, and 1100 °C, respectively, using Al(OH)3 and (NH4)3PO4·3H2O as starting materials. Effects of the synthesis temperatures and CaSO4 addition on properties of the porous AlPO4 ceramics were investigated elaborately. The experimental results revealed that water absorption and open porosity of the porous AlPO4 ceramics decreased remarkably with increasing of the powder synthesis temperatures from 800 to 1100 °C and with rising of the CaSO4 addition from 0 to 15 wt%, respectively. The SEM micrographs disclosed glass phase in the porous AlPO4 ceramics decreased markedly as the powder synthesis temperatures rose from 800 to 1100 °C. It was assumed that the formation of AlPO4 owing to the reaction of Al(PO3)3 to the residual Al2O3 could lead to considerable volume expansion and thus resulted in larger water absorption and open porosity.

Similar content being viewed by others

References

Baitalik, S., Kayal, N.: Processing and properties of cordierite-silica bonded porous SiC ceramics. Ceram Int. 43, 14683–14692 (2017)

Vakifahmetoglu, C., Zeydanli, D., Colombo, P.: Porous polymer derived ceramics. Mater Sci Eng R. 106, 1–30 (2016)

Wei, G.S., Huang, P.R., Xu, C., Chen, L., Ju, X., Du, X.Z.: Experimental study on the radiative properties of open-cell porous ceramics. Sol Energy. 149, 13–19 (2017)

Matsunaga, C., Fukushima, M., Hyuga, H., Yoshizawa, Y.: Fabrication of porous silica ceramics by gelation-freezing of diatomite slurry. J Eur Ceram Soc. 37, 5259–5264 (2017)

Kazantseva, L.K., Rashchenko, S.V.: Optimization of porous heat-insulating ceramics manufacturing from zeolitic rocks. Ceram Int. 42, 19259–19265 (2016)

Lee, E., Lee, M., Shim, J., Min, K., Kim, D.J.: Microstructure formation of porous silicon carbide ceramics during β-α phase transformation. Int J Refract Met Hard Mater. 65, 64–68 (2017)

Chen, Z.W., Wang, X., Atkinson, A., Brandon, N.: Spherical indentation of porous ceramics: cracking and toughness. J Eur Ceram Soc. 36, 3473–3480 (2016)

Shimizu, T., Matsuura, K., Furue, H., Matsuzak, K.: Thermal conductivity of high porosity alumina refractory bricks made by a slurry gelation and foaming method. J Eur Ceram Soc. 33, 3429–3435 (2013)

Bai, C.Y., Deng, X.Y., Li, J.B., Jing, Y.N., Jiang, W.K.: Preparation and properties of mullite-bonded porous SiC ceramics using porous alumina as oxide. Mater Charact. 90, 81–87 (2014)

Vogt, U.F., Györfy, L., Herzog, A., Graule, T., Plesch, G.: Macroporous silicon carbide foams for porous burner applications and catalyst supports. J Phys Chem Solids. 68, 1234–1238 (2007)

Julbe, A., Rouessac, V., Durand, J., Ayral, A.: New approaches in the design of ceramic and hybrid membranes. J Memb Sci. 316, 176–185 (2008)

Heidenreich, S., Haag, W., Salinger, M.: Next generation of ceramic hot gas filter with safety fuses integrated in venturi ejectors. Fuel. 108, 19–23 (2013)

Kleps, I., Angelescu, A., Samfierscu, N., Gil, A., Correia, A.: Study of porous silicon, silicon carbide and DLC coated field emitters for pressure sensor application. Solid State Electron. 45, 997–1001 (2001)

Mazumder, S., Sarkar, N., Park, J.G., Zhao, W., Kim, S., Kim, I.J.: A novel processing of carbon nanotubes grown on molecular sieve coated porous ceramics. Chem Phys Lett. 635, 334–338 (2015)

Machida, M., Murakami, K., Hinokuma, S., Uemura, K., Ikeue, K., Matsuda, M., Chai, M., Nakahara, Y., Sato, T.: AlPO4 as a support capable of minimizing threshold loading of Rh in automotive catalysts. Chem Mater. 21, 1796–1798 (2009)

Westdijk, J., Metz, B., Spruit, N., Tilstra, W., van der Gun, J., Hendriksen, C., Kersten, G.: Antigenic fingerprinting of diphtheria toxoid adsorbed to aluminium phosphate. Biologicals. 47, 69–75 (2017)

Chang, Q.Y., He, H., Zhao, J.C., Yang, M., Qu, J.H.: Bactericidal activity of a Ce-promoted Ag/AlPO4 catalyst using molecular oxygen in water. Environ Sci Technol. 42, 1699–1704 (2008)

Yang, F.L., Zhang, W., Chi, Z.X., Cheng, F.Q., Chen, J.T., Cao, A.M., Wan, L.J.: Controlled formation of core–shell structures with uniform AlPO4 nanoshells. Chem Commun. 51, 2943–2945 (2015)

Sheng, N., Chu, Y.Y., Xin, S.H., Wang, Q., Yi, X.F., Feng, Z.C., Meng, X.J., Liu, X.L., Deng, F., Xiao, F.S.: Insights of the crystallization process of molecular sieve AlPO4-5 prepared by solvent-free synthesis. J Am Chem Soc. 138, 6171–6176 (2016)

Estevez, R., Lopez-Pedrajas, S., Luna, D., Bautista, F.M.: Microwave-assisted etherification of glycerol with tert-butyl alcohol over amorphous organosilica-aluminum phosphates. Appl Catal B. 213, 42–52 (2017)

Estevez, R., Lopez-Pedrajas, S., Blanco-Bonilla, F., Luna, D., Bautista, F.M.: Production of acrolein from glycerol in liquid phase on heterogeneous catalysts. Chem Eng J. 282, 179–186 (2015)

Vivero-Escoto, J.L., Chiang, Y.D., Wu, K., Yamauchi, Y.: Recent progress in mesoporous titania materials: adjusting morphology for innovative applications. Sci Technol Adv Mater. 13, 013003 (2012)

Suzuki, N., Sakka, Y., Yamauchi, Y.: Simple preparation of silica and alumina with a hierarchical pore system via the dual-templating method. Sci Technol Adv Mater. 10, 025002 (2009)

Wang, Q., Ramachandran, C.S., Smith, G.M., Sampath, S.: Sliding wear behavior of air plasma sprayed Al2O3 coatings sealed with aluminum phosphate. Tribol Int. 116, 431–439 (2017)

Wazer, J.R.V.: Phosphorus and its Compounds. Interscience Publishers, New York (1958)

Itoh, M., Takehara, M., Saito, M.: NOx Reduction Activity over Phosphate-Supported Platinum Catalysts with Hydrogen Under Oxygen-Rich Condition, 3rd International Congress on Ceramics, 18 2011

Li, W.Y., Zhu, Y., Guo, X.Z., Nakanishi, K., Kanamori, K., Yang, H.: Preparation of a hierarchically porous AlPO4 monolith via an epoxide-mediated sol-gel process accompanied by phase separation. Sci Technol Adv Mater. 14, 045007 (2013)

Cai, X.B., Zhu, W.J., Yang, H., Xu, C.Y., Nakanishi, K., Kanamori, K., Guo, X.Z.: Preparation of silver nanoparticles embedded hierarchically porous AlPO4 monoliths. New J Chem. 39, 6238–6243 (2015)

Morris, J.H., Perkins, P.G., Rose, A.E.A., Smith, W.E.: The relationship between the binding properties of a composite from aluminium dihydrogen phosphate and silica and the crystal habit of the aluminium dihydrogen phosphate. J appl Chem Biotechnol. 28, 756–760 (1978)

Fu, L.P., Gu, H.Z., Huang, A., Ni, H.W.: Correlations among processing parameters and porosity of a lightweight alumina. Ceram Int. 44, 14076–14081 (2018)

Lin, X.L., Wen, Y., Li, N.: Phase composition and pore evolution of porous periclase-spinel ceramics prepared from magnesite and Al(OH)3. Sci Sinter. 48(2), 147–155 (2016)

Yan, W., Chen, Q.J., Lin, X.L., Li, N.: Pore characteristics and phase compositions of porous corundum-mullite ceramics prepared from kaolinite gangue and Al(OH)3 with different amount of CaCO3 addition. J Ceram Soc Jpn. 123(9), 897–902 (2015)

Yan, W., Lin, X.L., Chen, J.F., Li, N., Wei, Y.W., Han, B.Q.: Effect of TiO2 addition on microstructure and strength of porous spinel (MgAl2O4) ceramics prepared from magnesite and Al(OH)3. J Alloys Compd. 618, 287–291 (2015)

Yan, W., Chen, J.F., Li, N., Qiu, W.D., Wei, Y.W., Han, B.Q.: Preparation and characterization of porous MgO-Al2O3 refractory aggregates using an in-situ decomposition pore-forming technique. Ceram Int. 41(1A), 515–520 (2015)

Yan, W., Li, N., Han, B.Q.: Preparation and characterization of porous ceramics prepared from kaolinite gangue and Al(OH)3 with double addition of MgCO3 and CaCO3. Int J Miner Metall Mater. 18(4), 450–454 (2011)

Funding

This work is financially support by the University and City Joint Project of Zibo Municipal Government, China (grant no. 2017ZBXC059).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, J., Li, XQ., He, J. et al. Fabrication and properties of porous AlPO4 ceramics from solid-state synthesized powders using Al(OH)3 and ammonium phosphate as raw materials. J Aust Ceram Soc 55, 601–609 (2019). https://doi.org/10.1007/s41779-018-0268-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-018-0268-2