Abstract

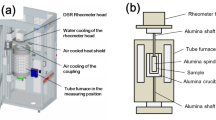

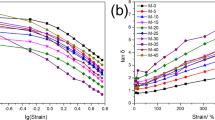

Experiments were conducted to study the relation of pyroplastic deformation and liquid viscosity in vitreous ceramics. The pyroplastic deformation was researched through experimentation in a muffle furnace. The quenching method was introduced to gain the chemical composition of liquid phase in the sample. The experiment was carried out in a tube furnace. The Riboud model was selected to calculate the liquid viscosities based on the comprehensive consideration of different viscosity models. Generally, the small viscosity value of liquid phase in the sample at high temperature accelerates the deformation of the sample. On the other hand, the deformation is retarded if the viscosity value of the generated liquid phase is thicker than 2 × 104 Pa s. The chemical composition of the sample and the secondary mullite phase in the sample are other parameters which strongly impact the pyroplastic deformation of vitreous china.

Similar content being viewed by others

References

Koga, N., Taneo, M., Yasuda, M., Tateyama, S., Matsumoto, A., Nishikawa, T., Otsu, M. and Hongo, F.: Ceramics, ceramic blank, manufacturing method thereof, sanitary earthenware and manufacturing method thereof. U.S. Patent, 6242117, 2001

Porte, F., Brydson, R., Rand, B., Riley, F.L.: Creep viscosity of vitreous china. J Am Ceram Soc. 87, 923–928 (2004)

Tuncel, D.Y., Özel, E.: Evaluation of pyroplastic deformation in sanitaryware porcelain bodies. Ceram Int. 38, 1399–1407 (2012)

Deng, T., Liu, B., Xu, X., Wu, J.: The effect of different solid phases on the pyroplastic deformation of porcelain. J Ceram Soc Japan. 123, 1004–1009 (2015)

Henderson, H.B., Caldwell Henderson, J.H.: Increase in refractoriness in ceramic bodies in interrupted heat treatment. J Am Ceram Soc. 11, 795–802 (1928)

Lee, S., Messing, G.L., Green, D.J.: Bending creep test to measure the viscosity of porous materials during sintering. J Am Ceram Soc. 86, 877–882 (2003)

Iida, T., Sakai, H., Kita, Y., Murakami, K.: Equation for estimating viscosities of industrial mold fluxes. High Temperature Materials and Processes. 19, 153–164 (2011)

Mills, K.C.: The influence of structure on the physico-chemical properties of slags. ISIJ Int. 33, 148–155 (1993)

Urbain, G., Cambier, H., Deletter, M., Anseau, M.R.: Viscosity of silicate melts. Trans Brit Ceram Soc. 80, 139–141 (1981)

Riboud, P.V., Roux, Y., Lucas, D., Gaye Facber, H.: Improvement of continuous casting powders. Hüttenprax Metallweiter Verarb. 19, 859–869 (1981)

Urbain, G., Boiret, M.: Viscosities of liquid silicates. Ironmak Steelmak. 17, 255–260 (1990)

Tang, X., Ma, M.: A description of slag viscosity model and the prediction capability. China Nonferrous Metallurgy. 44, 18–23 (2015)

Sichen, D., Bygden, J., Seetharaman, S.: A model for estimation of viscosities of complex metallic and ionic melts. Metall Mater Trans B Process Metall Mater Process Sci. 25, 519–525 (1994)

Clark, D.E., Hench, L.L., Acree, W.A.: Electron microprobe analysis of Na2O-CaO-SiO2 glass [J]. J Am Ceram Soc. 58, 531 (1975)

Borom, M.P., Hanneman, R.E.: Local compositional changes in alkali silicate glasses during electron microprobe analysis. J Appl Phys. 38, 2406–2407 (1967)

Iqbal, Y., Lee, W.E.: Fired porcelain microstructure revisited. J Am Ceram Soc. 82, 3584–3590 (1999)

Einstein, A.: Berichtigung zu meiner Arbeit: Eine neue Bestimmung der Moleküldimensionen. Ann D Phys. 34, 591–592 (1911)

Roscoe, R.: The end correction for rotation viscometers. Br J Appl Phys. 3, 267–269 (1952)

Happel, J.: Viscosity of suspensions of uniform spheres. J Appl Phys. 28, 1288–1292 (1957)

Mooney, M.: The viscosity of a concentrated suspension of spherical particles. J Colloids Sci. 6, 162–170 (1951)

Liu, B., Xu, X., Wu, J., Deng, T.: Effect of calcite on pyroplastic deformation of sanitary ware. J ceram (Chinese). 37, 338–344 (2016)

Acknowledgements

The financial supports on the Project 51502230 from the National Natural Science Foundation of China are gratefully acknowledged. The authors are thankful to Prof. Liushun Wu from Anhui University of Technology for his valuable suggestions and thermodynamic calculation by FactSage 7.0.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, T., Fang, J. & Lan, S. The relation of pyroplastic deformation and liquid viscosity in vitreous ceramics. J Aust Ceram Soc 53, 635–643 (2017). https://doi.org/10.1007/s41779-017-0075-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-017-0075-1