Abstract

Multiple steady-state solution (MSS) phenomena not only have a special effect on the design and optimization of distillation separation process, but also can provide some instructive information during the actual production. Thus, it is necessary to find out an easy and effective method to predict whether there exist multiple steady-state solutions or not. Based on previous researches and the Kremser group method, this research proposes a simple method, using a mathematical equation, to predict MSS occurring in the thermally coupled distillation separation column. Besides, Aspen plus simulator is employed to carry out rigorous simulation verification. By validation analysis, this method is relatively simple and effective for predicting the MSS occurring in the thermal-coupled distillation.

Similar content being viewed by others

References

Amminudin KA, Smith R (2001) Design and optimization of fully thermally coupled distillation columns. Chem Eng Res Des 79(7):716–724

Asprion N, Kaibel G (2010) Dividing wall columns: fundamentals and recent advances. Chem Eng Process 49:8

Dejanovi’c I, Matijaˇsevi’c L, Oluji’c Z (2010) Dividing wall column—a breakthrough towards sustainable distilling. Chem Eng Process 49:22

Dejanović I, Matijašević L, Jansen H, Olujić Ž (2011) Designing a packed dividing wall column for an aromatics processing plant. Ind Eng Chem Res 50(9):5680–5692

Ehlers C, Egger T, Fieg G (2017) Experimental operation of a reactive dividing wall column and comparison with simulation results. AICHE J 63(3):1036–1050

Halvorsen IJ, Skogestad S (2003) Vmin diagram for a two-product column. Ind Eng Chem Res 42:9

Jacobsen EW, Skogestad S (1991) Multiple steady states in ideal two-product distillation. AICHE J 37(4):13

Kaibel G (1987) Distillation columns with vertical partitions. Chem Eng Technol 10(1):92–98

Kim YH (2017) An energy-efficient crude distillation unit with a prefractionator. Chem Eng Technol 40(3):588–597

Li WS, Zhong L, He YC, Meng JH, Yao FL, Guo YS, Xu CJ (2015) Multiple steady-states analysis and unstable operating point stabilization in homogeneous azeotropic distillation with intermediate entrainer. Ind Eng Chem Res 54(31):7668–7686

Li LM, Sun LY, Yang DL, Zhong W, Zhu Y, Tian YY (2016) Reactive dividing wall column for hydrolysis of methyl acetate: design and control. Chin J Chem Eng 24(10):1360–1368

Li LM, Guo LJ, Tu YQ, Yu N, Sun LY, Tian YY, Li QS (2017) Comparison of different extractive distillation processes for 2-methoxyethanol/toluene separation: design and control. Comput Chem Eng 99:117–134

Lin W-J, Seader JD, Wayburn TL (1987) Computing multiple solutions to systems of interlinked separation columns. AICHE J 33(6):12

Lomelí-Rodríguez M, Rivera-Toledo M, López-Sánchez JA (2017) Process intensification of the synthesis of biomass-derived renewable polyesters: reactive distillation and divided wall column polyesterification. Ind Eng Chem Res 56(11):3017–3032

Long H, Clark J, Benyounes H, Shen W, Dong L, Wei S a (2016) Optimal design and economic evaluation of dividing-wall columns. Chem Eng Technol 39(6):1077–1086

Patrascu I, Bildea CS, Kiss AA (2017) Dynamics and control of a heat pump assisted extractive dividing-wall column for bioethanol dehydration. Chem Eng Res Des 119:66–74

Petlyuk FB, Platonov VM, Slavinsk DM (1965) Thermodynamically optimal method for separating multicomponent mixtures. Int Chem Eng 5(3):555

Purohit JL, Mahajani SM, Patwardhan SC (2013) Analysis of steady-state multiplicity in reactive distillation columns. Ind Eng Chem Res 52(14):5191–5206

Qian X, Jia S, Skogestad S, Yuan XG, Luo YQ (2016a) Model predictive control of reactive dividing wall column for the selective hydrogenation and separation of a C3 stream in an ethylene plant. Ind Eng Chem Res 55(36):9738–9748

Qian X, Jia SK, Luo YQ, Yuan XG, Yu KT (2016b) Control of reactive dividing wall column for selective hydrogenation and separation of C3 stream. Chin J Chem Eng 24(9):1213–1228

Rafael CC, Seader JD, Wayburn TL (1986) Multiple steady-state solutions for interlinked separation systems. Ind.eng.chem.fundamen 25(4):566–576

Rodriguez M, Li PZ, Diaz I (2017) A control strategy for extractive and reactive dividing wall columns. Chem Eng Process 113:14–19

Chavez R, Seader JD, Waybur TL (1986) Multiple steady-state solutions for interlinked separation systems. Ind Eng Chem Fundam 25:11

Song E, Li S, Wang E (2019) Dynamic analysis for the multi-steady states in the dividing wall column. Process Integr Optim Sustain. 3(2):179–187

Song E, Wang E (2017) Design of dividing wall column considering its multiple steady state characteristic. Chem Eng Technol 41(3)

Sun L, Bi X (2014) Shortcut method for the design of reactive dividing wall column. Ind Eng Chem Res 53(6):2340–2347

Tututi-Avila S, Dominguez-Diaz LA, Medina-Herrera N, Jimenez-Gutierrez A, Hahn J (2017) Dividing-wall columns: design and control of a kaibel and a satellite distillation column for BTX separation. Chem Eng Process 114(1–15):1–15

Uwitonze H, Han S, Hwang KS (2014a) New design method for fully thermally coupled distillation column using group and approximate methods. Ind Eng Chem Res 53(30):11979–11988

Uwitonze H, Han S, Kim S, Hwang KS (2014b) Structural design of fully thermally coupled distillation column using approximate group methods. Chem Eng Process 85:155–167

Uwitonze H, Goyal A, Kim S, Kim S, Hwang KS (2014c) Fenske and Kremser group methods in the design of fully thermally coupled distillation column. Comput Aided Chem Eng 33:1705–1710

Van Duc Long N, Lee M (2012) Dividing wall column structure design using response surface methodology. Comput Chem Eng 37:119–124

Wang E (2015) Simulation and analysis of multiple steady states in dividing wall column. Asia Pac J Chem Eng 10:9

Xu L, Li M, Yin X, Yuan X (2017) New intensified heat integration of vapor recompression assisted dividing wall column. Ind Eng Chem Res 56(8):2188–2196

Yang BL, Wu J, Zhao GS, Wang HJ, Lu SQ (2006) Multiplicity analysis in reactive distillation column using ASPEN PLUS. Chin J Chem Eng 14(3):301–308

Yildirim Ö, Kiss AA, Kenig EY (2011) Dividing wall columns in chemical process industry_ a review on current activities. Sep Purif Technol 80:15

Yuan Y, Huang KJ, Chen HS, Zhang LA, Wang SF (2017) Asymmetrical temperature control of a BTX dividing-wall distillation column. Chem Eng Res Des 123:84–98

Zhai J, Liu YL, Li LM, Zhu Y, Zhong W, Sun LY (2015) Applications of dividing wall column technology to industrial-scale cumene production. Chem Eng Res Des 102:138–149

Zhu Z, Liu X, Cao Y, Liang S, Wang Y (2017) Controllability of separate heat pump distillation for separating isopropanol-chlorobenzene mixture. Korean J Chem Eng 34(3):866–875

Zong X, Huang KJ, Yuan Y, Chen HS, Yu JP (2015) Design and operation of dividing-wall distillation columns. 2. Process dynamics and operation. Chem Eng Process 91:89–103

Funding

This work is supported by the National Natural Science Foundation of China (No. 21376240).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix. Nomenclature

Appendix. Nomenclature

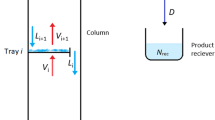

MSS, multiple steady states: OPs, operation parameters: DFs, degrees of freedom: TCDC, thermal-coupled distillation column: DWC, divided wall column: RR, reflux ratio: D, distillate product: S, side stream product: B, bottom product: F, feed stream: R, lthe liquid split ratio: Rv, the vapor split ratio

Rights and permissions

About this article

Cite this article

Erwei, S., Lijuan, Q. & Erqiang, W. Prediction for Multi-Steady-State Solutions in the Thermal-Coupled Distillation. Process Integr Optim Sustain 3, 505–514 (2019). https://doi.org/10.1007/s41660-019-00095-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-019-00095-6