Abstract

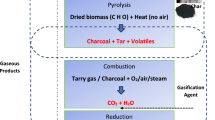

Gasification has been one of the most attractive and common biomass conversion processes for recent years. The existence of an accurate and dynamic model frees us from carrying out time-consuming and expensive tests. In this study, to eliminate the complexity of dynamic models, a hybrid model is used for modeling the process of wood-fixed bed gasification. Firstly, an equilibrium model is developed to obtain the mole fractions of product flow and the equilibrium temperature of the flaming pyrolysis zone. The equilibrium model is applied as the initial condition of the unsteady one-dimensional kinetic model for the reduction zone. The couple of heat and mass equations in the gas phase are solved by considering the kinetic of main reactions in the reduction zone using MATLAB software. Oxygen is considered gasifying agent instead of air. The results indicate a good agreement with previous relevant researches. In the equivalence ratio of 0.35, the maximum mole fraction of hydrogen as the most valuable syngas has obtained. In this optimum ER, the equilibrium temperature of flaming pyrolysis zone has been calculated to be 1012 K, and the gasifier outlet temperature at gas-phase velocity within 0.1–1 m/s is 890–952 K. The final mole fractions of CO and H2 as the main products of the process are 0.46 and 0.36, respectively. The heating value of produced syngas equals 10.8 MJ/m3 that is 120% higher than the average heating value when the air is utilized as the gasifier agent.

Similar content being viewed by others

Abbreviations

- A :

-

Pre-exponential factor

- a :

-

Number of moles of oxygen per mole of biomass

- Ash:

-

Ash content of dry biomass

- C :

-

Molar concentration (mol/m3)

- C p :

-

Molar-specific heats (J/mol K)

- D i :

-

Diffusion coefficient (m2)

- d p :

-

Particle diameter (m)

- E :

-

Activation energy (kJ)

- ER:

-

Equivalence ratio

- FC:

-

Activation energy

- MC:

-

Moisture content in the fuel in mass percentage

- g ° :

-

Gibbs function (J/mol)

- \( {{\overline{h}}_{\mathrm{f}}}^0 \) :

-

Enthalpy of formation (kJ/mol)

- HHV:

-

Higher heating value (MJ/kg)

- k :

-

Equilibrium constant

- k m :

-

Mass transfer coefficient (m/s)

- k ∗ m :

-

Maximum value of the mass transfer coefficient (m/s)

- M:

-

Molecular weight (g/mol)

- P :

-

Gas pressure (kPa)

- Q loss :

-

Heat loss (kJ)

- r :

-

Specific reaction rate (mol/(m3 s))

- R :

-

Universal gas constant (J/(mol K)

- Re :

-

Particle Reynolds number

- Sc:

-

Particle Schmidt number

- T :

-

Temperature (K)

- t :

-

Time (s)

- U g :

-

Gas-phase velocity (m/s)

- w :

-

Number of moles of moisture for per mole of biomass

- x :

-

Number of moles

- Y :

-

Mole fraction

- z :

-

Distance (m)

- ε :

-

Porosity

- ν p :

-

Particle density number (1/m)

- ρ g :

-

Gas-phase density (kg/m3)

- λ g :

-

Gas-phase thermal conductivity (J/(mol K))

- ΔH :

-

Reaction enthalpy (kJ/mol)

- α :

-

Stoichiometric coefficient

- 0:

-

Initial or ambient condition

- a :

-

Air

- in:

-

Inlet

- i :

-

Species

References

Adib R (2016) Renewables 2015 global status report. REN21 Secretariat, Paris, France

Aydin ES, Yucel O, Sadikoglu H (2017) Development of a semi-empirical equilibrium model for downdraft gasification systems. Energy 130:86–98

Babu BV, Sheath PN (2006) Modeling and simulation of reduction zone of downdraft biomass gasifier: effect of char reactivity factor. Energy Convers Manag 47(15):2602–2611

Basu P (2010) Biomass gasification and pyrolysis: practical design and theory. Academic, Cambridge

Di Blasi C (2000) Dynamic behaviour of stratified downdraft gasifiers. Chem Eng Sci 55(15):2931–2944

Di Blasi C (2004) Modeling wood gasification in a countercurrent fixed-bed reactor. AIChE J 50(9):2306–2319

Di Blasi C, Branca C (2013) Modeling a stratified downdraft wood gasifier with primary and secondary air entry. Fuel 104:847–860

Gao N, Li A (2008) Modeling and simulation of combined pyrolysis and reduction zone for a downdraft biomass gasifier. Energy Convers Manag 49(12):3483–3490

Ghassemi H, Shahsavan-Markadeh R (2014) Effects of various operational parameters on biomass gasification process; a modified equilibrium model. Energy Convers Manag 79:18–24

Giltrap DL, McKibbin R, Barnes GRG (2003) A steady state model of gas-char reactions in a downdraft biomass gasifier. Sol Energy 74(1):85–91

Gordillo ED, Belghit A (2011) A downdraft high temperature steam-only solar gasifier of biomass char: a modelling study. Biomass Bioenergy 35(5):2034–2043

Hameed S, Ramzan N, Rahman Z-u, Zafar M, Riaz S (2014) Kinetic modeling of reduction zone in biomass gasification. Energy Convers Manag 78:367–373

Jaojaruek K (2014) Mathematical model to predict temperature profile and air–fuel equivalence ratio of a downdraft gasification process. Energy Convers Manag 83:223–231

Liu H, Gibbs BM (2003) Modeling NH 3 and HCN emissions from biomass circulating fluidized bed gasifiers. Fuel 82(13):1591–1604

Masmoudi MA, Sahraoui M, Grioui N, Halouani K (2014) 2-D modeling of thermo-kinetics coupled with heat and mass transfer in the reduction zone of a fixed bed downdraft biomass gasifier. Renew Energy 66:288–298

McKendry P (2002) Energy production from biomass (part 3): gasification technologies. Bioresour Technol 83(1):55–63

Melgar A, Perez JF, Laget H, Horillo A (2007) Thermochemical equilibrium modelling of a gasifying process. Energy Convers Manag 48(1):59–67

Molino A, Chianese S, Musmarra D (2016) Biomass gasification technology: the state of the art overview. J Energy Chem 25(1):10–25

Patra TK, Sheth PN (2015) Biomass gasification models for downdraft gasifier: a state-of-the-art review. Renew Sust Energ Rev 50:583–593

Patra TK, Nimisha KR, Sheth PN (2016) A comprehensive dynamic model for downdraft gasifier using heat and mass transport coupled with reaction kinetics. Energy 116:1230–1242

Poling BE, Prausnitz JM, O'connell JP (2001) The properties of gases and liquids, vol 5. Mcgraw-Hill, New York

Ratnadhariya JK, Channiwala SA (2009) Three zone equilibrium and kinetic free modeling of biomass gasifier—a novel approach. Renew Energy 34(4):1050–1058

Rosillo-Calle F, Woods J (2012) The biomass assessment handbook: bioenergy for a sustainable environment. Earthscan, London

Roy PC, Datta A, Chakraborty N (2009) Modelling of a downdraft biomass gasifier with finite rate kinetics in the reduction zone. Int J Energy Res 33(9):833–851

Salem AM, Paul MC (2018) An integrated kinetic model for downdraft gasifier based on a novel approach that optimises the reduction zone of gasifier. Biomass Bioenergy 109:172–181

Sansaniwal SK, Pal K, Rosen MA, Tyagi SK (2017) Recent advances in the development of biomass gasification technology: a comprehensive review. Renew Sust Energ Rev 72:363–384

Sharma AK (2008) Equilibrium and kinetic modeling of char reduction reactions in a downdraft biomass gasifier: a comparison. Sol Energy 82(10):918–928

Sheth PN, Babu BV (2009) Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresour Technol 100(12):3127–3133

Simone M, Nicolella C, Tognotti L (2013) Numerical and experimental investigation of downdraft gasification of woody residues. Bioresour Technol 133:92–101

Tinaut FV, Melgar A, Perez JF, Horrillo A (2008) Effect of biomass particle size and air superficial velocity on the gasification process in a downdraft fixed bed gasifier. An experimental and modelling study. Fuel Process Technol 89(11):1076–1089

Vaezi M, Fard MP, Moghiman M (2008) On a numerical model for gasification of biomass materials, an alternative method to combustion. In: Proceeding of 2nd National Combustion Conference, Mashad, Iran

Wang Y, Kinoshita CM (1993) Kinetic model of biomass gasification. Sol Energy 51(1):19–25

Yan W-C, Shen Y, You S, Sim SH, Luo Z-H, Tong YW, Wang C-H (2018) Model-based downdraft biomass gasifier operation and design for synthetic gas production. J Clean Prod 178:476–493

Zainal ZA, Ali R, Lean CH, Seetharamu KN (2001) Prediction of performance of a downdraft gasifier using equilibrium modeling for different biomass materials. Energy Convers Manag 42(12):1499–1515

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fani, M., Haddadzadeh Niri, M. & Joda, F. A Simplified Dynamic Thermokinetic-Based Model of Wood Gasification Process. Process Integr Optim Sustain 2, 269–279 (2018). https://doi.org/10.1007/s41660-018-0042-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41660-018-0042-5