Abstract

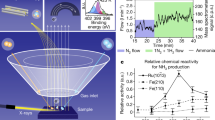

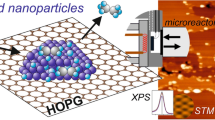

An in-depth understanding of the structure–activity relationship between the surface structure, chemical composition, adsorption and desorption of molecules, and their reaction activity and selectivity is necessary for the rational design of high-performance catalysts. Herein, we present a method for studying catalytic mechanisms using a combination of in situ reaction cells and surface science techniques. The proposed system consists of four parts: preparation chamber, temperature-programmed desorption (TPD) chamber, quick load-lock chamber, and in situ reaction cell. The preparation chamber was equipped with setups based on the surface science techniques used for standard sample preparation and characterization, including an Ar+ sputter gun, Auger electron spectrometer, and a low-energy electron diffractometer. After a well-defined model catalyst was prepared, the sample was transferred to a TPD chamber to investigate the adsorption and desorption of the probe molecule, or to the reaction cell, to measure the catalytic activity. A thermal desorption experiment for methanol on a clean Cu(111) surface was conducted to demonstrate the functionality of the preparation and TPD chambers. Moreover, the repeatability of the in situ reaction cell experiment was verified by CO2 hydrogenation on the Ni(110) surface. At a reaction pressure of 800 Torr at 673 K, turnover frequencies for the methanation reaction and reverse water–gas shift reaction were 0.15 and 7.55 Ni atom−1 s−1, respectively.

Similar content being viewed by others

Data availability

The data that support the findings of this study are openly available in Science Data Bank at https://doi.org/10.57760/sciencedb.j00186.00074 and https://cstr.cn/31253.11.sciencedb.j00186.00074.

References

M. Boudart, B.H. Davis, H. Heinemann, Introduction, in Handbook of Heterogeneous Catalysis. ed. by G. Ertl, H. Knözinger, J. Weitkamp (Wiley, 1997), pp.1–48. https://doi.org/10.1002/9783527619474.ch1

C. Reece, R.J. Madix, Moving from fundamental knowledge of kinetics and mechanisms on surfaces to prediction of catalyst performance in reactors. ACS Catal. 11, 3048–3066 (2021). https://doi.org/10.1021/acscatal.0c05173

IEA (2021) World Energy Outlook 2021, IEA, Paris https://www.IEA.org/Reports/World-Energy-Outlook-2021.

D. Wang, Z. Xie, M.D. Porosoff et al., Recent advances in carbon dioxide hydrogenation to produce olefins and aromatics. Chemistry 7, 2277–2311 (2021). https://doi.org/10.1016/j.chempr.2021.02.024

X. Jiang, X. Nie, X. Guo, C. Song et al., Recent advances in carbon dioxide hydrogenation to methanol via heterogeneous catalysis. Chem. Rev. 120, 7984–8034 (2020). https://doi.org/10.1021/acs.chemrev.9b00723

M. Wang, L. Luo, C. Wang et al., Heterogeneous catalysts toward CO2 hydrogenation for sustainable carbon cycle. Acc. Mater. Res. 3, 565–571 (2022). https://doi.org/10.1021/accountsmr.2c00006

J. Low, J. Ma, J. Wan et al., Identification and design of active sites on photocatalysts for the direct artificial carbon cycle. Acc. Mater. Res. 3, 331–342 (2022). https://doi.org/10.1021/accountsmr.1c00222

D. Gao, R.M. Arán-Ais, H.S. Jeon et al., Rational catalyst and electrolyte design for CO2 electroreduction towards multicarbon products. Nat. Catal. 2, 198–210 (2019). https://doi.org/10.1038/s41929-019-0235-5

G.A. Somorjai, Y. Li, Introduction to Surface Chemistry and Catalysis, 2nd edn. (Wiley, 2010)

Y. Liu, D. Deng, X. Bao, Catalysis for selected C1 chemistry. Chem. 6, 2497–2514 (2020). https://doi.org/10.1016/j.chempr.2020.08.026

G. Ertl, Reactions at surfaces: from atoms to complexity (Nobel Lecture). Angew. Chem. Int. Ed. 47, 3524–3535 (2008). https://doi.org/10.1002/anie.200800480

F. Morfin, L. Piccolo, A versatile elevated-pressure reactor combined with an ultrahigh vacuum surface setup for efficient testing of model and powder catalysts under clean gas-phase conditions. Rev. Sci. Instrum. 84, 094101 (2013). https://doi.org/10.1063/1.4818669

J. Cai, Q. Dong, Y. Han et al., An APXPS endstation for gas–solid and liquid–solid interface studies at SSRF. Nucl. Sci. Tech. 30, 81 (2019). https://doi.org/10.1007/s41365-019-0608-0

R. Chang, R.-Z. Tai, D.E. Starr et al., Synchrotron radiation-based ambient pressure photoelectron spectroscopy and its applications. Nucl. Tech. 35, 481–485 (2012). (in Chinese)

H. Wu, Y. Yang, P.H.L. Jerry et al., A novel apparatus for operando rapid characterization on real reaction: design and application. Nucl. Tech. 39, 100101 (2016). https://doi.org/10.11889/j.0253-3219.2016.hjs.39.100101 (in Chinese)

L. Mayr, R. Rameshan, B. Klotzer et al., Combined UHV/high-pressure catalysis setup for depth-resolved near-surface spectroscopic characterization and catalytic testing of model catalysts. Rev. Sci. Instrum. 85, 055104 (2014). https://doi.org/10.1063/1.4874002

A.L. Cabrera, N.D. Spencer, E. Kozak et al., Improved instrumentation to carry out surface analysis and to monitor chemical surface reactions in situ on small area catalysts over a wide pressure range (10–8 – 105 Torr). Rev. Sci. Instrum. 53, 1888–1893 (1982). https://doi.org/10.1063/1.1136899

J. Rodriguez, D.W. Goodman, High-pressure catalytic reactions over single-crystal metal surfaces. Surf. Sci. Rep. 14, 1–107 (1991). https://doi.org/10.1016/0167-5729(91)90002-F

R. Imbihl, G. Ertl, Oscillatory kinetics in heterogeneous catalysis. Chem. Rev. 95, 697–733 (1995). https://doi.org/10.1021/cr00035a012

J.Y. Park, L.R. Baker, G.A. Somorjai, Role of hot electrons and metal–oxide interfaces in surface chemistry and catalytic reactions. Chem. Rev. 115, 2781–2817 (2015). https://doi.org/10.1021/cr400311p

G.A. Somorjai, R.L. York, D. Butcher et al., The evolution of model catalytic systems; studies of structure, bonding and dynamics from single crystal metal surfaces to nanoparticles, and from low pressure (<10−3 Torr) to high pressure (>10−3 Torr) to liquid interfaces. Phys. Chem. Chem. Phys. 9, 3500–3513 (2007). https://doi.org/10.1039/b618805b

F. Faisal, M. Bertram, C. Stumm et al., Preparation of complex model electrocatalysts in ultra-high vacuum and transfer into the electrolyte for electrochemical IR spectroscopy and other techniques. Rev. Sci. Instrum. 89, 114101 (2018). https://doi.org/10.1063/1.5047056

F. Faisal, C. Stumm, M. Bertram et al., Electrifying model catalysts for understanding electrocatalytic reactions in liquid electrolytes. Nat. Mater. 17, 592–598 (2018). https://doi.org/10.1038/s41563-018-0088-3

C. Li, J. Cai, T. Yang et al., In-situ studies of CO oxidation on Pt(110). Nucl. Tech. 41, 120501 (2018). https://doi.org/10.11889/j.0253-3219.2018.hjs.41.120501 (in Chinese)

T. Yang, T. Gu, Y. Han et al., Surface orientation and pressure dependence of CO2 activation on Cu surfaces. J. Phys. Chem. C 124, 27511–27518 (2020). https://doi.org/10.1021/acs.jpcc.0c08262

T. Koitaya, Y. Shiozawa, Y. Yoshikura et al., Systematic study of adsorption and the reaction of methanol on three model catalysts: Cu(111), Zn–Cu(111), and oxidized Zn–Cu(111). J. Phys. Chem. C 121, 25402–25410 (2017). https://doi.org/10.1021/acs.jpcc.7b09598

T.J. Lawton, J. Carrasco, A.E. Baber et al., Hydrogen-bonded assembly of methanol on Cu(111). Phys. Chem. Chem. Phys. 14, 11846–11852 (2012). https://doi.org/10.1039/C2CP41875D

R.B. David, A.B. Yaacov, B. Eren, Effect of surface orientation on methanol adsorption and thermally induced structural transformations on copper surfaces. J. Phys. Chem. C 125, 6099–6107 (2021). https://doi.org/10.1021/acs.jpcc.0c10278

J. Gong, D.W. Flaherty, R.A. Ojifinni et al., Surface chemistry of methanol on clean and atomic oxygen pre-covered Au(111). J. Phys. Chem. C 112, 5501–5509 (2008). https://doi.org/10.1021/jp0763735

J. Cai, Y. Han, S. Chen et al., CO2 activation on Ni(111) and Ni(100) surfaces in the presence of H2O: an ambient-pressure X-ray photoelectron spectroscopy study. J. Phys. Chem. C 123, 12176–12182 (2019). https://doi.org/10.1021/acs.jpcc.8b11698

C. Vogt, E. Groeneveld, G. Kamsma et al., Unravelling structure sensitivity in CO2 hydrogenation over nickel. Nat. Catal. 1, 127–134 (2018). https://doi.org/10.1038/s41929-017-0016-y

K. Christmann, O. Schober, G. Ertl, Adsorption of CO on a Ni(111) surface. J. Chem. Phys. 60, 4719–4724 (1974). https://doi.org/10.1063/1.1680972

C. Vogt, M. Monai, E.B. Sterk et al., Understanding carbon dioxide activation and carbon–carbon coupling over nickel. Nat. Commun. 10, 5330 (2019). https://doi.org/10.1038/s41467-019-12858-3

E.B. Sterk, A.E. Nieuwelink, M. Monai et al., Structure sensitivity of CO2 conversion over nickel metal nanoparticles explained by micro-kinetics simulations. JACS Au. 2, 2714–2730 (2022). https://doi.org/10.1021/jacsau.2c00430

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Yi-Jing Zang, Shu-Cheng Shi, and Yong Han. Zhi Liu, Hui Zhang, Wei-Jia Wang, Peng Liu, and Mao Ye provided a great help to the study. The first draft of the manuscript was written by Yi-Jing Zang, Shu-Cheng Shi and Yong Han, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

Zhi Liu is an editorial board member for Nuclear Science and Techniques and was not involved in the editorial review, or the decision to publish this article. All authors declare that there are no competing interests.

Additional information

This work was supported by the National Natural Science Foundation of China (Nos. 21802096, 21832004, 21902179, 21991152, and 21991150) and the Shanghai XFEL Beamline Project (SBP) (31011505505885920161A2101001). H.Z. acknowledges the support of the Shanghai Sailing Program (19YF1455600).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zang, YJ., Shi, SC., Han, Y. et al. Combination of a reaction cell and an ultra-high vacuum system for the in situ preparation and characterization of a model catalyst. NUCL SCI TECH 34, 65 (2023). https://doi.org/10.1007/s41365-023-01228-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41365-023-01228-w