Abstract

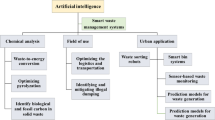

As various environments such as fine dust changing recently, there are many changes in agriculture. In particular, plants that grow in an environment where fine dust contains heavy metals are very dangerous for food. Because eating plants contaminated with heavy metals can be very harmful to human health. In light of this, plant factory is recognized as an important technology to solve this problem. So, this study is about how to design and operate plant factory using artificial intelligence. The results of the study were as follows. Plant factory can produce plants without time and space constraints by artificially controlling the environment. In plant factory, automation using the Internet of Things and artificial intelligence is recognized as a key technology during the Fourth Industrial Revolution. Using these technologies, plants can be automatically controlled and produced on a planned basis. Artificial intelligence collects the results of plant factory and goes through a deep learning process. Through this deep learning process, artificial intelligence analyzes the optimal cultivation conditions of crops. Plant factory targets to automatically provide an optimal environment for each crop. And, plant factory can farm by utilizing city buildings or idle spaces. So, this is the core agricultural technology of the future society. It also suggests how to use artificial intelligence in plant factory. This research result can be used as theoretical basic data in the design and construction of plant factory in urban idle space.

Similar content being viewed by others

References

Uoon CI et al (2017) Optimal cultivar selection of kohlrabi for hydroponics culture in a closed-type plant factory system. Prot Hortic Plant Fact 26(4):297–300

Hwang YH et al (2016) Effects of LED (light emitting diode) photoperiod and light intensity on growth and yield of Taraxacum coreanum Nakai in a plant factory. Prot Hortic Plant Fact 25(4):232–239

Um YC et al (2010) The development of container-type plant factory and growth of leafy vegetables as affected by different light sources. J Bio-Environ Control 19(4):333–342

Hwang SI et al (2015) ICT-based smart farm factory systems through the case of hydroponic ginseng plant factory. J Korean Inst Commun Inf Sci 40(4):780–790

Ko JH et al (2019) PLC automatic control for IOT based hydroponic plant factory. Comput Electron Agric 23(2):487–494

Lim GJ (2015) A design of IT-convergence plant factory system using the renewable energy. Inf Process Agric 40(4):769–779

Lee JE et al (2015) An analysis of the professional’s cognition regarding the plant factory feasibility. J Digit Converg 13(12):89–97

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hyunjin, C., Sainan, H. A study on the design and operation method of plant factory using artificial intelligence. Nanotechnol. Environ. Eng. 6, 41 (2021). https://doi.org/10.1007/s41204-021-00136-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41204-021-00136-x