Abstract

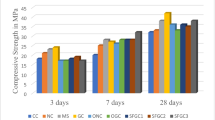

This research aimed to investigate the behavior of bond strength of reinforcing bar in recycled concrete aggregate with and without ground palm oil fuel ash (GPOFA) as a supplementary cementitious material. Recycled concrete aggregate (RCA) was used as a coarse aggregate, and local river sand was used as a fine aggregate. Portland cement type I was replaced by GPOFA at the rates of 0, 15%, 25%, and 35% by weight of the binder to cast concrete. Compressive strength and bond strength of the concrete were determined at the ages of 7, 28, and 90 days. A 16-mm deformed bar was inserted at a center of the 200-mm concrete cube, with the bond length of the steel bar embedded in concrete being four times the bar diameter or 64 mm. Linear variable differential transformer (LVDT) was installed at the bottom and top of the steel bar to investigate the relationship between bond strength and the slip of the steel bar. The results indicated that the compressive and bond strengths of the concrete decreased with an increase in GPOFA replacement. Due to the lower compressive strength, the replacement of ordinary Portland cement (OPC) with a greater amount of GPOFA decreased the bonding strength of concrete containing natural coarse aggregate and recycled coarse aggregate. Moreover, the bond strength between the reinforcing bar and RCA concrete was similar to that of the normal concrete when the compressive strengths of both concretes were similar.

Similar content being viewed by others

References

Department of primary industries and mines (2020) https://www.dpim.go.th/en/dpiminfo.php. Accessed 1 Feb 2020

Saini BS, Singh SP (2022) Estimation of flexural fatigue strength of self-compacting concrete made with coarse recycled concrete aggregates. Innov Infrast Sol 7(22):1–18. https://doi.org/10.1007/s41062-021-00606-w

Hachemi S, Khattab M, Benzetta H (2022) The effects of recycled brick and water/cement ratios on the physical and mechanical performance of recycled aggregates concrete. Innov Infrast Sol 7:332. https://doi.org/10.1007/s41062-022-00913-w

Pedro MPS, Samuel CM, Mercedes DGC, Irina DR, Guillermo RGC (2022) Use of fly ash in the production of geopolymers: a literature review. Innov Infrast Sol 7:236. https://doi.org/10.1007/s41062-022-00835-7

Chindaprasirt P, Homwuttiwong S, Jaturapitakkul C (2007) Strength and water permeability of concrete containing palm oil fuel ash and rice husk-bark ash. Constr Build Mater 21(9):1492–1499. https://doi.org/10.1016/j.conbuildmat.2006.06.015

Tavakoli M, Soroureddin SM (1996) Recycled concrete as a source of aggregate. In: proceedings of the international symposium on recycling of demolished concrete and masonry pp. 61–71

de Oliveira JR, Vazquez E (1999) Influence of recycled aggregates on the mechanical properties of concrete. ACI Mater J 96(2):159–166

Ravindrarajah RS, Tam CT (1985) Properties of concrete made with crushed concrete as coarse aggregate. Mag of Con Res 37(130):29–38. https://doi.org/10.1680/macr.1985.37.130.29

Limbachiya MC, Leelawat T, Dhir RK (2000) Use of recycled concrete aggregates in high strength concrete. Mat Struct 33(9):574–580. https://doi.org/10.1007/BF02480538

Poon CS, Kou SC, Lam L, Fok H (2004) Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr Build Mater 18(5):295–299. https://doi.org/10.1016/j.conbuildmat.2004.07.001

Etxeberria M, Vázquez E, Marí AR, Barra M (2007) Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem Conc Res 37(5):735–742. https://doi.org/10.1016/j.cemconres.2007.02.002

Butler L, West JS, Tighe SL (2011) The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem Conc Res 41:1037–1049. https://doi.org/10.1016/j.cemconres.2011.06.004

Arezoumandi M, Looney TJ, Volz JS (2015) Effect of fly ash replacement level on the bond strength of reinforcing steel in concrete beams. J Clean Prod 87:745–751. https://doi.org/10.1016/j.jclepro.2014.10.078

Office of agricultural economics (2016) Agricultural statistics of Thailand. Forecasting production, marketing and price trends for 2016–2017. http://www.oae.go.th/download/download_journal/2560. Accessed 1 Feb 2016

Tanchirapat W, Tangpagasit J, Waewkum S, Jaturapitakkul C (2003) A new pozzolanic material from palm oil fuel ash. KMUTT Res Dev J 26(4):459–473

Sata V, Jaturapitakkul C, Kiattikomol K (2004) Utilization of palm oil fuel ash in high-strength concrete. J Mater Civ Eng 16(6):623–628. https://doi.org/10.1061/(asce)0899-1561(2004)16:6(623)

Chindaprasirt P, Rukzon S, Sirivivatnanon V (2008) Effect of carbon dioxide on chloride penetration and chloride ion diffusion coefficient of blended Portland cement mortar. Constr Build Mater 22:1701–1707. https://doi.org/10.1016/j.conbuildmat.2007.06.002

Li L, Liu X, Wang X, Sun Z, Gao X (2018) Experimental investigation on compressive and flexural strength, and durability of recycled aggregate concrete containing ground powder of blast furnace slag. Constr Build Mater 162:309–319. https://doi.org/10.1016/j.conbuildmat.2022.128512

Chindaprasirt P, Rukzon S, Ekarin P (2019) Properties and microstructure of recycled aggregate concrete containing ground powder of blast furnace slag. J Clean Prod 208:493–503. https://doi.org/10.1016/j.conbuildmat.2019.02.011

Zheng W, Cao W, Zhang L, Ma X, Wang Y (2018) Microstructure and mechanical properties of recycled aggregate concrete containing ground POFA and GGBFS. Constr Build Mater 170:8–15

Okafor FO, Nwachukwu JN (2019) Environmental and economic benefits of using groundnut shell ash in concrete production. J Clean Prod 227:787–798

Hasan NMS, Sobuz MHR, Shaurdho NMN, Meraz MM, Datta SD, Aditto FS, Kabbo MKI, Miah MJ (2023) Eco-friendly concrete incorporating palm oil fuel ash: Fresh and mechanical properties with machine learning prediction, and sustainability assessment. Heliyon 9(11):e22296. https://doi.org/10.1016/j.heliyon.2023.e22296

TIS: 24-2548 (2005) Steel bars for reinforced concrete: deformed bars. Thai industrial standards institute, Bangkok

ASTM: C494 (2012) Standard specification for chemical admixture for concrete. American society for testing and materials, West Conshohocken

ASTM: C39 (2012) Standard test method for compressive strength of cylindrical concrete specimens. American society for testing and materials, West Conshohocken

ASTM: D7913 (2014) Standard test method for bond strength of fiber-reinforced polymer matrix composite bars to concrete by pullout testing. American society for testing and materials, West Conshohocken

ASTM: C234-91a (1991) Standard test method for comparing concretes on the basis of the bond developed with reinforcing steel. American society for testing and materials, West Conshohocken

Rilem TC (1994) Rc6 bond test for reinforcement steel. 2. Pull out test. In: Rilem TC (ed) RILEM recommendations for the testing and use of constructions materials. Rilem, Paris, pp 218–220

Sanawang W, Cheewaket T, Tanchirapat W, Jaturapitakkul C (2017) Influence of palm oil fuel ash and w/b ratios on compressive strength, water permeability, and chloride resistance of concrete. Adv Mater Sci Eng 3:1–8. https://doi.org/10.1155/2017/4927640

Chindaprasirt P, Chotetanorm C, Rukzon S (2010) Use of palm oil fuel ash to improve chloride and corrosion resistance of high-strength and high-workability concrete. J Mater Civ Eng 23:499–503. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000187

ASTM: C33/C33M-16 (2016) Standard specification for concrete aggregates. American society for testing and materials, West Conshohocken

Chen HJ, Yen T, Chen KH (2003) Use of building rubbles as recycled aggregates. Cem Conc Res 33(1):125–132. https://doi.org/10.1016/S0008-8846(02)00938-9

Hansen TC, Narud H (1983) Strength of recycled concrete made from crushed concrete coarse aggregate. Con Inter 5(1):79–83

Gomez-Soberon MV (2002) Porosity of recycled concrete with substitution of recycled concrete aggregate: an experimental study. Cem Conc Res 32(8):1301–1311. https://doi.org/10.1016/S0008-8846(02)00795-0

Duan ZH, Poon CS (2014) Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater Des 58:19–29. https://doi.org/10.1016/j.matdes.2014.01.044

BS: 812/110 (1990) Methods for determination of aggregate crushing value (ACV). British standard institute, London

Ajdukiewicz A, Kliszczewicz A (2002) Influence of recycled aggregates on mechanical properties of HS/HPC. Cem Concr Compos 24(2):269–279. https://doi.org/10.1016/S0958-9465(01)00012-9

Aslam M, Shafigh P, Jumaat MZ (2016) Drying shrinkage behavior of structural lightweight aggregate concrete containing blended oil palm bio-products. J Clean Prod 127:183–194. https://doi.org/10.1016/j.jclepro.2016.03.165

Chindaprasirt P, Jaturapitakkul C, Sinsiri T (2005) Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem Concr Compos 27(4):425–428. https://doi.org/10.1016/j.cemconcomp.2004.07.003

Kiattikomol K, Jaturapitakkul C, Songpiriyakij S, Chutubtim S (2001) A study of ground coarse fly ashes with different finenesses from various sources as pozzolanic materials. Cem Concr Compos 23(4–5):335–343. https://doi.org/10.1016/S0958-9465(01)00016-6

Erdoğdu K, Türker P (1998) Effects of fly ash particle size on strength of Portland cement fly ash mortars. Cem Conc Res 28(9):1217–1222. https://doi.org/10.1016/S0008-8846(98)00116-1

Slanička Š (1991) The influence of fly ash fineness on the strength of concrete. Cem Conc Res 21(2–3):285–296. https://doi.org/10.1016/0008-8846(91)90010-F

Payá J, Monzó J, Peris-Mora E, Borrachero MV, Tercero R, Pinillos C (1995) Early-strength development of Portland cement mortars containing air classified fly ashes. Cem Conc Res 25(2):449–456. https://doi.org/10.1016/0008-8846(95)00031-3

Sinsiri T, Kroehong W, Jaturapitakkul C, Chindaprasirt P (2012) Assessing the effect of biomass ashes with different finenesses on the compressive strength of blended cement paste. Mater Des 42:424–433. https://doi.org/10.1016/j.matdes.2012.06.030

Lam L, Wong YL, Poon CS (2008) Degree of hydration and gel/space ratio of high volume fly ash/cement systems. Cem Conc Res 30(5):747–756. https://doi.org/10.1016/S0008-8846(00)00213-1

Ezziane K, Bougara A, Kadri A, Khelafi H, Kadri E (2007) Compressive strength of mortar containing natural pozzolan under various curing temperature. Cem Concr Compos 29(8):587–593. https://doi.org/10.1016/j.cemconcomp.2007.03.002

Arezoumandi M, Wolfe MH, Volz JS (2013) A comparative study of the bond strength of reinforcing steel in high-volume fly ash concrete and conventional concrete. Constr Build Mater 40:919–924. https://doi.org/10.1016/j.conbuildmat.2012.11.105

John Robert Prince M, Singh B (2013) Bond behavior of deformed steel bars embedded in recycled aggregate concrete. Constr Build Mater 49:852–862. https://doi.org/10.1016/j.conbuildmat.2013.08.031

Kiran T, Andrushia D, El Hachem C, Kanagaraj BNA, Azab M (2023) Effect of nano cementitious composites on corrosion resistance and residual bond strength of concrete. Rin Eng 18:1–12. https://doi.org/10.1016/j.rineng.2023.101064

Hwangbo D, Son DH, Suh H, Sung J, Bae BI, Bae S, So H, Choi CS (2023) Effect of nanomaterials (carbon nanotubes, nano-silica, graphene oxide) on bond behavior between concrete and reinforcing bars. C Stu Constr Mater 18:1–15. https://doi.org/10.1016/j.cscm.2023.e02206

ACI: 318e08 (2008) Building code requirements for structural concrete and commentary. American Concrete Institute, Indiana

CEB-FIP (1990) CEB-FIP model code for concrete structures. Bulletin Euro international committee for concrete, London

ACI: 408R-03 (2003) Bond and development of straight reinforcing bars in tension. American concrete institute, Indiana

Mo KH, Yeap KW, Alengaram UJ, Jumaat MZ, Bashar II (2018) Bond strength evaluation of palm oil fuel ash-based geopolymer normal weight and lightweight concretes with steel reinforcement. J Ad Sci Tech 32(1):1–17. https://doi.org/10.1080/01694243.2017.1336195

Kim SW, Yun HD, Park WS, Jang YI (2015) Bond strength prediction for deformed steel rebar embedded in recycled coarse aggregate concrete. Mater Des 83:257–269. https://doi.org/10.1016/j.matdes.2015.06.008

Amnadnua K, Tangchirapat W, Jaturapitakkul C (2013) Strength, water permeability, and heat evolution of high strength concrete made from the mixture of calcium carbide residue and fly ash. Mater Des 51:894–901. https://doi.org/10.1016/j.matdes.2013.04.099

Dueramae S, Tangchirapat W, Chindaprasirt P, Jaturapitakkul C (2016) Influence of activation methods on strength and chloride resistance of concrete using calcium carbide residue-fly ash mixture as a new binder. J Mater Civ Eng 29(4):1–8. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001808

Krammart P, Martputhorn S, Jaturapitakkul C, Ngaopisadarn V (1996) A study of compressive strength of mortar made from calcium carbide residue and fly ash. Res Dev J Eng Inst of Thai 7(2):65–75

Sindy S, González-Fonteboa B, Eiras-López J, Herrador MF (2014) Bond behavior between steel reinforcement and recycled concrete. Mat Struc 47(1–2):323–334. https://doi.org/10.1617/s11527-013-0063-z

Ubagaram J, Mahmud H, Jumaat MZ (2010) Comparison of mechanical and bond properties of oil palm kernel shell concrete with normal weight concrete. Int J Phys Sci 5(8):1231–1239

Acknowledgements

This work was supported by the research funding from the Faculty of Engineering and Architecture, Uthenthawai Campus, Rajamangala University of Technology, Tawan-ok, Thailand. The authors also extended their gratitude for the support provided by the Thailand Science Research and Innovation (TSRI) Basic Research Fund: Fiscal year 2024 (Advance and Sustainable Construction toward Thailand 4.0).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

We wish confirm that there are no known conflicts of interest associated with this publication and has been no significant support for this work that could have influenced its outcome.

We confirm that the manuscript has read and approved by all name authors and that there are no other persons who satisfied the criteria for authorship but are no listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sripan, T., Haruehansapong, S., Kroehong, W. et al. Assessment of bonding strength of steel bar in recycled aggregate concrete containing ground palm oil fuel ash. Innov. Infrastruct. Solut. 9, 59 (2024). https://doi.org/10.1007/s41062-023-01360-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01360-x