Abstract

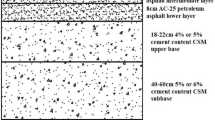

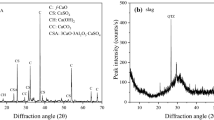

In order to study the growth pattern of compressive strength and adiabatic temperature rise of cement-stabilized macadam (CSM), preparing CSM with different structures and different cement admixtures. Seven grades of CSM were studied experimentally by means of porosity ratio, permeability coefficient, mechanical property and adiabatic temperature rise tests. It was found that the unconfined compressive strength of cement-stabilized macadam of various structures increased with the increase of maintenance time, and the strength of cement-stabilized macadam grew fastest in the first 28 day, and then the growth gradually slowed down. The growth law of unconfined compressive strength and splitting tensile strength of cement-stabilized macadam was investigated, and the growth model of compressive strength of CSM was established. For CSM, the temperature rise rate not only depends on the cement admixture but also is closely related to the aggregate skeleton structure. The adiabatic temperature rise model applicable to CSM was further established, and it was proposed that the fitting of the CSM trend by the CSM temperature rise growth formula is consistent with the actual measurement curve, and the cement-stabilized macadam temperature-growth equation has a good physical meaning and is suitable for the temperature simulation calculation of CSM, and the research results can make more accurate temperature history during the construction of large volume CSM prediction.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are included within the article.

References

Guo Y, Yao C, Shen A et al (2020) Feasibility of rapid-regeneration utilization in situ for waste cement-stabilized macadam. J Clean Prod 263:121452

Song L, Song Z, Wang C et al (2019) Arch expansion characteristics of highway cement-stabilized macadam base in Xinjiang, China. Constr Build Mater 215:264–274

Tang L, Xiao Y, Xie J (2020) Fatigue cracking checking of cement stabilized macadam based on measurement uncertainty and interval analysis. Constr Build Mater 250:118921

Yan K, Li G, You L et al (2020) Performance assessments of open-graded cement stabilized macadam containing recycled aggregate. Constr Build Mater 233:117326

Yan K, Sun H, Gao F et al (2020) Assessment and mechanism analysis of municipal solid waste incineration bottom ash as aggregate in cement stabilized macadam. J Clean Prod 244:118750

Abdellatief M, Elrahman MA, Alanazi H et al (2023) A state-of-the-art review on geopolymer foam concrete with solid waste materials: components, characteristics, and microstructure. Innov Infrastruct Solut 8(9):1–26

Abd Ellatief M, Abadel AA, Federowicz K et al (2023) Mechanical properties, high temperature resistance and microstructure of eco-friendly ultra-high performance geopolymer concrete: role of ceramic waste addition. Constr Build Mater 401:132677

Abdellatief M, Elrahman MA, Elgendy G et al (2023) Response surface methodology-based modelling and optimization of sustainable UHPC containing ultrafine fly ash and metakaolin. Constr Build Mater 388:131696

Deng C, Jiang Y, Yuan K et al (2020) Mechanical properties of vertical vibration compacted lime–fly ash-stabilized macadam material. Constr Build Mater 251:119089

Du S (2019) Mechanical properties and shrinkage characteristics of cement stabilized macadam with asphalt emulsion. Constr Build Mater 203:408–416

Lv S, Xia C, You L et al (2019) Unified fatigue characteristics model for cement-stabilized macadam under various loading modes. Constr Build Mater 223:775–783

Priyadharshini P, Ramamurthy K, Robinson RG (2018) Reuse potential of stabilized excavation soil as fine aggregate in cement mortar. Constr Build Mater 192:141–152

Yan K, Gao F, Sun H et al (2019) Effects of municipal solid waste incineration fly ash on the characterization of cement-stabilized macadam. Constr Build Mater 207:181–189

Zheng Y, Zhang P, Cai Y et al (2019) Cracking resistance and mechanical properties of basalt fibers reinforced cement-stabilized macadam. Compos Part B, Eng 165:312–334

Guotang Z, Wei S, Guotao Y et al (2017) Mechanism of cement on the performance of cement stabilized aggregate for high speed railway roadbed. Constr Build Mater 144:347–356

Zhao Y, Gao Y, Zhang Y et al (2016) Effect of fines on the mechanical properties of composite soil stabilizer-stabilized gravel soil. Constr Build Mater 126:701–710

Du S (2016) Influence of chemical additives on mixing procedures and performance properties of asphalt emulsion recycled mixture with reclaimed cement-stabilized macadam. Constr Build Mater 118:146–154

Liu C, Lv S, Peng X et al (2019) Normalized characterization method for fatigue behavior of cement-treated aggregates based on the yield criterion. Constr Build Mater 228:117099

Setyawan A (2013) Asessing the compressive strength properties of semi-flexible pavements. Procedia Eng 54:863–874

Zheng C, Zhao D, Chen C et al (2013) Quantitative test technology study on the mesoscopic strength parameters of the mineral aggregate contact surface of bituminous-stabilized macadam. Constr Build Mater 40:622–631

Jing P, Song X, Zhang J et al (2022) A review of hydro-mechanical coupling behaviour of cement-treated materials. Constr Build Mater 322:126446

Xuan DX, Houben LJM, Molenaar AAA et al (2012) Mechanical properties of cement-treated aggregate material—a review. Mater Des 33:496–502

Deng C, Jiang Y, Lin H et al (2019) Mechanical-strength-growth law and predictive model for cement-stabilized macadam. Constr Build Mater 215:582–594

Deng C, Jiang Y, Tian T et al (2021) Resilient modulus and influencing factors of vertical vibration compacted cement-stabilized macadam. Int J Pavement Eng 22(11):1435–1445

Jiang Y, Xue J (2019) Investigation into physical and mechanical properties of SRX-stabilised crushed rock using different compaction methods. Int J Pavement Eng 20(7):866–873

Xue J, Jiang Y (2017) Analysis on the fatigue properties of vertical vibration compacted lime–fly ash-stabilized macadam. Constr Build Mater 155:531–541

Yi Y, Jiang Y, Tian T et al (2022) Mechanical-strength-growth law and predictive model for ultra-large size cement-stabilized macadam based on the vertical vibration compaction method. Constr Build Mater 324:126691

General Administration of Quality Supervision, Inspection and Quarantine of the People 's Republic of China. General Portland cement: GB175-2007/XG3-2018. China Communications Press, Beijing (2018) (in Chinese)

Ministry of Transport of the People's Republic of China.Test methods of aggregate for highway engineering. JTG E42—2005. China Communications Press, Beijing (in Chinese)

China Sandstone Association. Construction sand: GBT14684-2011. China Communications Press, Beijing (in Chinese)

Ministry of Transport of the People’s Republic of China, Testing Methods ofMaterial Stabilized with Inorganic Binders for Highway Engineering (JTG E51-2009). China Communications Press, Beijing (in Chinese)

Costa A (2006) Permeability-porosity relationship; a reexamination of the Kozeny–Carman equation based on a fractal pore-space geometry assumption. Geophys Res Lett 33(2):L2318

Whitaker S (1996) The Forchheimer equation; a theoretical development. Transp Porous Media 25(1):27–61

De Schutter G, Taerwe L (1995) General hydration model for portland cement and blast furnace slag cement. Cem Concr Res 25(3):593–604

Di Luzio G, Cusatis G (2009) Hygro-thermo-chemical modeling of high performance concrete. I: theory. Cem Concr Compos 31(5):301–308

Jeong DJ, Kim T, Ryu J et al (2021) Analytical model to parameterize the adiabatic temperature rise of concrete. Constr Build Mater 268:121656

Lee Y, Kim J (2009) Numerical analysis of the early age behavior of concrete structures with a hydration based microplane model. Comput Struct 87(17–18):1085–1101

Pang X, Sun L, Sun F et al (2021) Cement hydration kinetics study in the temperature range from 15 °C to 95 °C. Cem Concr Res 148:106552

Zhou W, Qi T, Liu X et al (2019) A meso-scale analysis of the hygro-thermo-chemical characteristics of early-age concrete. Int J Heat Mass Transf 129:690–706

Acknowledgements

This research is financially supported by the National Nature Science Foundation of China (No.51768016 No.52068005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals perfonmed by any of the authors.

Informed consent

For this type of study formal consent is not required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, T., Liang, J., Rong, H. et al. Modelling of physical and mechanical properties and adiabatic temperature rise of cement-stabilized macadam. Innov. Infrastruct. Solut. 8, 332 (2023). https://doi.org/10.1007/s41062-023-01288-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01288-2