Abstract

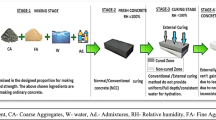

The population growth resulted in a sharp surge in construction work. Water is required for the mixing, curing and monitoring of cement hydration processes in concrete. In self-curing concrete, the availability of additional internal water that was not mixed in, causes the cement to hydrate. Due to the fact that concrete cures from the inside out, self-curing concrete helps to reduce water waste. Concrete that cures on its own totally eliminates the risk of diminished strength and durability from improper curing. In order to produce eco-friendly self-curing concrete, the current study examines the mechanism of self-curing, several techniques for producing self-curing concrete and the impact self-curing agents. Polyethylene glycol, lightweight expanded clay aggregates, lightweight aggregate, superabsorbent polymers, superfine powders, and natural fibres as curing agents used effectively as a self-curing agent in order to achieve effective results. Present study reviews the feasibility of producing low and high-strength self-curing concrete with judicious utilization of various self-curing agents. The discussion also included the utilisation techniques of curing agents in the production of self-curing concrete considering physical, mechanical, and microstructure aspects. Adopting self-curing agents in concrete improves hydration process, mechanical characteristics, durability, crack susceptibility behaviour, and capacity to reduce drying and autogenous shrinkage. Additionally, reduction in permeability observed and the interfacial transition zone between the curing agent and the cement paste matrix has improved.

Similar content being viewed by others

Data availability

Data is contained within the article.

Abbreviations

- LECA:

-

Lightweight expanded clay aggregates

- LWA:

-

Lightweight aggregate

- SAP:

-

Superabsorbent polymers

- LWS:

-

Lightweight sand

- SAP:

-

Super-absorbent polymers

- PEG:

-

Polyethylene glycol

- ITZ:

-

Interfacial transition zone

- NAPCC:

-

Nation action plan for climate change

- PU:

-

Pumice stone

- CH:

-

Calcium hydroxide

- ε:

-

Strain

- K:

-

Bulk modulus

- Ks :

-

Modulus of its solid backbone

- S:

-

Level of saturation

- R:

-

Constant

- T:

-

Absolute temperature

- RH:

-

Relative humidity

- Vm :

-

Molar volume of the pore solution

- HCP:

-

Hardened cement paste

- BC:

-

Brick chips

- RH:

-

Relative humidity

- RA:

-

Recycled aggregates

- PCCA:

-

Porous ceramic coarse aggregates

- NF:

-

Natural fibres

- C-S-H:

-

Calcium silicate hydrates

- HPC:

-

High-performance concrete

- NSC:

-

Normal strength concrete

- HSC:

-

High strength concrete

- SEM:

-

The scanning electron microscopy

- UHPC:

-

Ultra-high-performance concrete

- BSE:

-

Backscattered electron

- SSA:

-

Steel slag aggregate

- CWA:

-

Ceramic waste aggregate

- WBA:

-

Waste brick aggregate

- RCA:

-

Recycled coarse aggregate

- WGA:

-

Waste glass aggregate

- EWA:

-

E-waste aggregate

- CSA:

-

Coconut shell aggregate

- OPSA:

-

Oil palm shell aggregate

- EPSA:

-

Expanded polystyrene aggregate

- LWECA:

-

Lightweight expanded clay aggregate

- WRTA:

-

Waste rubber tire aggregate

- CBFAA:

-

Cold bonded fly ash aggregate

- CBQDA:

-

Cold bonded quarry dust aggregate

- SFAA:

-

Sintered fly ash aggregate

References

Pandve H (2009) India’s national action plan on climate change. Indian J Occup Environ Med 13:17–19. https://doi.org/10.4103/0019-5278.50718

B. 456 (2000) Bureau of Indian Standards, New Delhi

El-Dieb AS (2007) Self-curing concrete: water retention, hydration and moisture transport. Constr Build Mater 21:1282–1287. https://doi.org/10.1016/j.conbuildmat.2006.02.007

Lee HXD, Wong HS, Buenfeld NR (2016) Self-sealing of cracks in concrete using superabsorbent polymers. Cem Concr Res 79:194–208. https://doi.org/10.1016/j.cemconres.2015.09.008

Nie S, Hu S, Wang F, Yuan P, Zhu Y, Ye J, Liu Y (2016) Internal curing—a suitable method for improving the performance of heat-cured concrete. Constr Build Mater 122:294–301. https://doi.org/10.1016/j.conbuildmat.2016.05.159

Mousa MI, Mahdy MG, Abdel-Reheem AH, Yehia AZ (2015) Self-curing concrete types; water retention and durability. Alex Eng J 54:565–575. https://doi.org/10.1016/j.aej.2015.03.027

Kamal MM, Safan MA, Bashandy AA, Khalil AM (2018) Experimental investigation on the behavior of normal strength and high strength self-curing self-compacting concrete. J Build Eng 16:79–93. https://doi.org/10.1016/j.jobe.2017.12.012

Kang SH, Hong SG, Moon J (2018) Importance of drying to control internal curing effects on field casting ultra-high performance concrete. Cem Concr Res 108:20–30. https://doi.org/10.1016/j.cemconres.2018.03.008

Liu J, Shi C, Ma X, Khayat KH, Zhang J, Wang D (2017) An overview on the effect of internal curing on shrinkage of high performance cement-based materials. Constr Build Mater 146:702–712. https://doi.org/10.1016/j.conbuildmat.2017.04.154

Shafigh P, Chai LJ, Bin Mahmud H, Nomeli MA (2018) A comparison study of the fresh and hardened properties of normal weight and lightweight aggregate concretes. J Build Eng 15:252–260. https://doi.org/10.1016/j.jobe.2017.11.025

Geiker MR, Bentz DP, Jensen OM (2004) Mitigating autogenous shrinkage by internal curing. Am Concr Institute ACI Spec Publ SP-218, pp 143–154. https://doi.org/10.14359/13060

Fahim Huseien G, Hussein Joudah Z, Pervez Memon R, Rahman Mohd Sam A (2020) Compressive strength and microstructure properties of modified concrete incorporated effective microorganism and fly ash. Mater Today Proc 46:2036–2044. https://doi.org/10.1016/j.matpr.2021.03.054

Soler JM (2007) Thermodynamic description of the solubility of C-S-H gels in hydrated Portland cement, pp 1–36

Fahim Huseien G, Hussein Joudah Z, Hafizah N, Khalid A, Rahman Mohd Sam A, Tahir MMd, Hasanah Abdul Shukor Lim N, Alyousef R, Mirza J (2021) Durability performance of modified concrete incorporating fly ash and effective microorganism. Constr Build Mater 267:120947. https://doi.org/10.1016/j.conbuildmat.2020.120947

Hamzah N, Saman HM, Baghban MH, Sam ARM, Faridmehr I, Sidek MNM, Benjeddou O, Huseien GF (2022) A review on the use of self-curing agents and its mechanism in high-performance cementitious materials. Buildings 12:1–27. https://doi.org/10.3390/buildings12020152

Gauffinet-Garrault S (2012) The rheology of cement during setting. Woodhead Publishing Limited, Berlin. https://doi.org/10.1533/9780857095282.1.96

Bentz D, Weiss J (2011) Internal Curing: A 2010 State-of-the-Art Review, NIST Interagency/Internal Report (NISTIR), National Institute of Standards and Technology, Gaithersburg, MD, pp 1–82 [online]. https://doi.org/10.6028/NIST.IR.7765. Accessed 26 Oct 2023

Bentz DP (1997) Three-dimensional computer simulation of Portland cement hydration and microstructure development. J Am Ceram Soc 80:3–21. https://doi.org/10.1111/j.1151-2916.1997.tb02785.x

Santosh PH, Arunkumar D, Aniruddha C (2018) Enhancement of plastic stage properties of self compacting concrete using nano composite particles. In: 11th international conference recent innovative science, engineering and management, pp 911–917

Jamali A, Mendes J, Nagaratnam B, Lim M (2022) A new four stage model of capillary pressure in early age concrete: insights from high capacity tensiometers. Cem Concr Res 161:106955. https://doi.org/10.1016/j.cemconres.2022.106955

Rajabipour F, Sant G, Weiss J (2008) Interactions between shrinkage reducing admixtures (SRA) and cement paste’s pore solution. Cem Concr Res 38:606–615. https://doi.org/10.1016/j.cemconres.2007.12.005

Shen D, Wang X, Cheng D, Zhang J, Jiang G (2016) Effect of internal curing with super absorbent polymers on autogenous shrinkage of concrete at early age. Constr Build Mater 106:512–522. https://doi.org/10.1016/j.conbuildmat.2015.12.115

Bentz D (2005) Curing with shrinkage-reducing admixtures: beyond drying shrinkage reduction. Concr Int 27:55–60

Silbey RJ, Alberty RA, Bawendi MG (1980) Physical chemistry, 4th edn. Wiley, Hoboken

Afzal S, Shahzada K, Fahad M, Saeed S, Ashraf M (2014) Assessment of early-age autogenous shrinkage strains in concrete using bentonite clay as internal curing technique. Constr Build Mater 66:403–409. https://doi.org/10.1016/j.conbuildmat.2014.05.051

Shen D, Wang M, Chen Y, Wang W, Zhang J (2017) Prediction of internal relative humidity in concrete modified with super absorbent polymers at early age. Constr Build Mater 149:543–552. https://doi.org/10.1016/j.conbuildmat.2017.05.121

Akcay B, Tasdemir MA (2010) Effects of distribution of lightweight aggregates on internal curing of concrete. Cem Concr Compos 32:611–616. https://doi.org/10.1016/j.cemconcomp.2010.07.003

Liu J, Shi C, Farzadnia N, Ma X (2019) Effects of pretreated fine lightweight aggregate on shrinkage and pore structure of ultra-high strength concrete. Constr Build Mater 204:276–287. https://doi.org/10.1016/j.conbuildmat.2019.01.205

Mousa MI, Mahdy MG, Abdel-Reheem AH, Yehia AZ (2015) Physical properties of self-curing concrete (SCUC). HBRC J 11:167–175. https://doi.org/10.1016/j.hbrcj.2014.05.001

Chaitanya C, Prasad P, Neeraja D, Ravitheja A (2019) Effect of LECA on mechanical properties of self-curing concrete. Mater Today Proc 19:484–488. https://doi.org/10.1016/j.matpr.2019.07.640

Manzur T, Iffat S, Noor MA (2015) Efficiency of sodium polyacrylate to improve durability of concrete under adverse curing condition. Adv Mater Sci Eng 2015:685785. https://doi.org/10.1155/2015/685785

Lura P (2005) Pumice aggregates for internal water curing, pp 137–151. https://doi.org/10.1617/2912143586.013

Meng W, Khayat K (2017) Effects of saturated lightweight sand content on key characteristics of ultra-high-performance concrete. Cem Concr Res 101:46–54. https://doi.org/10.1016/j.cemconres.2017.08.018

Weber S, Reinhardt HW (1997) New generation of high performance concrete: concrete with autogeneous curing. Adv Cem Based Mater 6:59–68. https://doi.org/10.1016/S1065-7355(97)00009-6

Shen D, Wang T, Chen Y, Wang M, Jiang G (2015) Effect of internal curing with super absorbent polymers on the relative humidity of early-age concrete. Constr Build Mater 99:246–253. https://doi.org/10.1016/j.conbuildmat.2015.08.042

Zhutovsky S, Kovler K, Bentur A (2004) Influence of cement paste matrix properties on the autogenous curing of high-performance concrete. Cem Concr Compos 26:499–507. https://doi.org/10.1016/S0958-9465(03)00082-9

Al Saffar DM, Al Saad AJK, Tayeh BA (2019) Effect of internal curing on behavior of high performance concrete: an overview. Case Stud Constr Mater 10:00229. https://doi.org/10.1016/j.cscm.2019.e00229

Ozer B, Ozkul MH (2004) The influence of initial water curing on the strength development of ordinary portland and pozzolanic cement concretes. Cem Concr Res 34:13–18. https://doi.org/10.1016/S0008-8846(03)00185-6

Zhutovsky S, Kovler K (2012) Effect of internal curing on durability-related properties of high performance concrete. Cem Concr Res 42:20–26. https://doi.org/10.1016/j.cemconres.2011.07.012

Wang XF, Fang C, Kuang WQ, Li DW, Han NX, Xing F (2017) Experimental investigation on the compressive strength and shrinkage of concrete with pre-wetted lightweight aggregates. Constr Build Mater 155:867–879. https://doi.org/10.1016/j.conbuildmat.2017.07.224

Sampebulu V (2012) Increase on strengths of hot weather concrete by self-curing of wet porous aggregate. Civ Eng Dimens. https://doi.org/10.9744/ced.14.2.92-99

Nguyen HD, Le HQ (2018) Water movement in Internally Cured Concrete. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/365/3/032029

Bentz DP, Hansen KK, Madsen HD, Vallée F, Griesel EJ (2001) Drying/hydration in cement pastes during curing. Mater Struct 34:557–565. https://doi.org/10.1007/BF02482182

Bentz D, Halleck P, Grader A, Roberts J (2006) Water movement during internal curing: direct observation using X-ray microtomography. Concr Int 28:39–45

Akhnoukh A (2016) Internal curing of concrete using light weight aggregates. Part Sci Technol. https://doi.org/10.1080/02726351.2016.1256360

Paul Á, Lopez M (2011) Assessing lightweight aggregate efficiency for maximizing internal curing performance. ACI Mater J 108:385–393

Zhutovsky S, Kovler K, Bentur A (2002) Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage. Mater Struct 35:97–101. https://doi.org/10.1007/BF02482108

Kim HK, Ha KA, Lee HK (2016) Internal-curing efficiency of cold-bonded coal bottom ash aggregate for high-strength mortar. Constr Build Mater 126:1–8. https://doi.org/10.1016/j.conbuildmat.2016.08.125

Han Y, Zhang J, Luosun Y, Hao T (2014) Effect of internal curing on internal relative humidity and shrinkage of high strength concrete slabs. Constr Build Mater 61:41–49. https://doi.org/10.1016/j.conbuildmat.2014.02.060

Zou D, Li K, Li W, Li H, Cao T (2018) Effects of pore structure and water absorption on internal curing efficiency of porous aggregates. Constr Build Mater 163:949–959. https://doi.org/10.1016/j.conbuildmat.2017.12.170

Castro J, Keiser L, Golias M, Weiss J (2011) Absorption and desorption properties of fine lightweight aggregate for application to internally cured concrete mixtures. Cem Concr Compos 33:1001–1008. https://doi.org/10.1016/j.cemconcomp.2011.07.006

Lura P, Wyrzykowski M, Tang C, Lehmann E (2014) Internal curing with lightweight aggregate produced from biomass-derived waste. Cem Concr Res 59:24–33. https://doi.org/10.1016/j.cemconres.2014.01.025

S.S. for L.A. for I.C. of Concrete, ASTM C1761 (2017)

Yang S, Wang L (2017) Effect of internal curing on characteristics of self-compacting concrete by using fine and coarse lightweight aggregates. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002044

Zou D, Weiss W (2014) Early age cracking behavior of internally cured mortar restrained by dual rings with different thickness. Constr Build Mater 66:146–153. https://doi.org/10.1016/j.conbuildmat.2014.05.032

Zhutovsky S, Kovler K, Bentur A (2002) Autogenous curing of High-Strength Concrete using pre-soaked pumice and perlite sand. In: Persson B, Fagerlund G (eds) Self-desiccation and its importance in concrete technology: proceedings of the third International Research Seminar in Lund, June 14–15, 2002, pp. 161–173

Şahmaran M, Lachemi M, Hossain KMA, Li VC (2009) Internal curing of engineered cementitious composites for prevention of early age autogenous shrinkage cracking. Cem Concr Res 39:893–901. https://doi.org/10.1016/j.cemconres.2009.07.006

Buchholz FL, Graham AT (1998) Modern superabsorbent polymer technology. Wiley, Hoboken, pp 1–304

Jensen OM (2011) Water absorption of superabsorbent polymers in a cementitious environment, pp 22–35

Wyrzykowski M, Lura P, Pesavento F, Gawin D (2011) Modeling of internal curing in maturing mortar. Cem Concr Res 41:1349–1356. https://doi.org/10.1016/j.cemconres.2011.04.013

Mechtcherine V, Wyrzykowski M, Schröfl C, Snoeck D, Lura P, De Belie N, Mignon A, Van Vlierberghe S, Klemm AJ, Almeida FCR, Tenório Filho JR, Boshoff WP, Reinhardt H-W, Igarashi S-I (2021) Application of super absorbent polymers (SAP) in concrete construction—update of RILEM state-of-the-art report. Mater Struct 54:80. https://doi.org/10.1617/s11527-021-01668-z

Zheng X, Han M, Liu L (2021) Effect of superabsorbent polymer on the mechanical performance and microstructure of concrete. Materials (Basel). https://doi.org/10.3390/ma14123232

Snoeck D, Pel L, De Belie N (2017) The water kinetics of superabsorbent polymers during cement hydration and internal curing visualized and studied by NMR. Sci Rep 7:9514. https://doi.org/10.1038/s41598-017-10306-0

Erk KA, Bose B (2018) Using polymer science to improve concrete: superabsorbent polymer hydrogels in highly alkaline environments. Am Chem Soc (ACS), Washington, pp 333–356. https://doi.org/10.1021/bk-2018-1296.ch017

Zhang J, Wang J, Ding X (2018) Calculation of shrinkage stress in concrete structures with impact of internal curing. Eng Fract Mech 192:54–76. https://doi.org/10.1016/j.engfracmech.2018.02.002

Kim YJ, Choi YW, Lachemi M (2010) Characteristics of self-consolidating concrete using two types of lightweight coarse aggregates. Constr Build Mater 24:11–16. https://doi.org/10.1016/j.conbuildmat.2009.08.004

Iffat S, Manzur T, Noor MA (2017) Durability performance of internally cured concrete using locally available low cost LWA. KSCE J Civ Eng 21:1256–1263. https://doi.org/10.1007/s12205-016-0793-x

Craeye B, Geirnaert M, De Schutter G (2011) Super absorbing polymers as an internal curing agent for mitigation of early-age cracking of high-performance concrete bridge decks. Constr Build Mater 25:1–13. https://doi.org/10.1016/j.conbuildmat.2010.06.063

Wehbe Y, Ghahremaninezhad A (2017) Combined effect of shrinkage reducing admixtures (SRA) and superabsorbent polymers (SAP) on the autogenous shrinkage, hydration and properties of cementitious materials. Constr Build Mater 138:151–162. https://doi.org/10.1016/j.conbuildmat.2016.12.206

Snoeck D, Schroefl C, Mechtcherine V (2018) Recommendation of RILEM TC 260-RSC: testing sorption by superabsorbent polymers (SAP) prior to implementation in cement-based materials. Mater Struct. https://doi.org/10.1617/s11527-018-1242-8

Schröfl C, Snoeck D, Mechtcherine V (2017) A review of characterisation methods for superabsorbent polymer (SAP) samples to be used in cement-based construction materials: report of the RILEM TC 260-RSC. Mater Struct Constr. https://doi.org/10.1617/s11527-017-1060-4

Mechtcherine V, Snoeck D, Schroefl C, De Belie N, Klemm A, Ichimiya K, Moon J, Wyrzykowski M, Lura P, Toropovs N, Assmann A, Igarashi S, la Varga I, Almeida F, Erk K, Ribeiro B, Custódio J, Reinhardt H, Falikman V (2018) Testing superabsorbent polymer (SAP) sorption properties prior to implementation in concrete: results of a RILEM Round-Robin Test. Mater Struct. https://doi.org/10.1617/s11527-018-1149-4

Ferfera-Harrar H, Nacera Aiouaz ND, Hadj-Hamou AS (2014) Preparation of chitosan-g-poly(acrylamide)/montmorillonite superabsorbent polymer composites: studies on swelling, thermal, and antibacterial properties. J Appl Polym Sci. https://doi.org/10.1002/app.39747

Lee HXD, Wong HS, Buenfeld NR (2018) Effect of alkalinity and calcium concentration of pore solution on the swelling and ionic exchange of superabsorbent polymers in cement paste. Cem Concr Compos 88:150–164. https://doi.org/10.1016/j.cemconcomp.2018.02.005

Kong X, Zhang Z, Lu Z (2014) Effect of pre-soaked superabsorbent polymer on shrinkage of high-strength concrete. Mater Struct. https://doi.org/10.1617/s11527-014-0351-2

Liu R, Sun Z, Ding Q, Chen P, Chen K (2017) Mitigation of early-age cracking of concrete based on a new gel-type superabsorbent polymer. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0001994

Bian X, Zeng L, Deng Y, Li X (2018) The role of superabsorbent polymer on strength and microstructure development in cemented dredged clay with highwater content. Polymers (Basel) 10:1–16. https://doi.org/10.3390/polym10101069

Riyazi S, Kevern J, Mulheron M (2017) Super absorbent polymers (SAPs) as physical air entrainment in cement mortars. Constr Build Mater 147:669–676. https://doi.org/10.1016/j.conbuildmat.2017.05.001

AzariJafari H, Kazemian A, Rahimi M, Yahia A (2016) Effects of pre-soaked super absorbent polymers on fresh and hardened properties of self-consolidating lightweight concrete. Constr Build Mater 113:215–220. https://doi.org/10.1016/j.conbuildmat.2016.03.010

Secrieru E, Mechtcherine V, Schroefl C, Borin D (2016) Rheological characterisation and prediction of pumpability of strain-hardening cement-based-composites (SHCC) with and without addition of superabsorbent polymers (SAP) at various temperatures. Constr Build Mater 112:581–594. https://doi.org/10.1016/j.conbuildmat.2016.02.161

Liu H, Bu Y, Sanjayan J, Nazari A, Shen Z (2016) The application of coated superabsorbent polymer in well cement for plugging the microcrack. Constr Build Mater 104:72–84. https://doi.org/10.1016/j.conbuildmat.2015.12.058

Dhir RK, Hewlett PC, Lota JS, Dyer TD (1994) An investigation into the feasibility of formulating “self-cure” concrete. Mater Struct 27:606–615. https://doi.org/10.1007/BF02473130

Dhir RK, Hewlett PC, Dyer TD (1998) Mechanisms of water retention in cement pastes containing a self-curing agent. Mag Concr Res 50:85–90. https://doi.org/10.1680/macr.1998.50.1.85

Chand MS, Giri PS, Kumar PR, Kumar GR, Raveena C (2012) Effect of self curing chemicals in self compacting mortars. J Immunol 188:753–764. https://doi.org/10.1016/j.conbuildmat.2016.01.018

Gencel O (2015) Characteristics of fired clay bricks with pumice additive. Energy Build 102:217–224. https://doi.org/10.1016/j.enbuild.2015.05.031

Akcay B, Tasdemir MA (2008) Internal curing of mortars by lightweight aggregates and its effects on hydration. Can J Civ Eng 35:1276–1284. https://doi.org/10.1139/L08-078

Karthika RB, Vidyapriya V, Nandhini Sri KV, Merlin Grace Beaula K, Harini R, Sriram M (2020) Experimental study on lightweight concrete using pumice aggregate. Mater Today Proc 43:1606–1613. https://doi.org/10.1016/j.matpr.2020.09.762

Rashad AM (2019) A short manual on natural pumice as a lightweight aggregate. J Build Eng 25:100802. https://doi.org/10.1016/j.jobe.2019.100802

Lura P, Bentz DP, Lange DA, Kovler K, Bentur A, Van Breugel K (2006) Measurement of water transport from saturated pumice aggregates to hardening cement paste. Mater Struct Constr 39:861–868. https://doi.org/10.1617/s11527-006-9137-5

Bhaskar Desai V, Sathyam A, Mallikarjunappa K (2014) An experimental investigation on some strength properties of light weight blended aggregate concrete. Int J Earth Sci Eng 7:349–355

Pravallika BD, Rao KV (2016) The Study on strength properties of light weight concrete using light weight aggregate. Int J Sci Res 5:1735–1739. https://doi.org/10.21275/v5i6.nov164521

Minapu LK, Ratnam MKMV, Rangaraju U (2014) Experimental study on light weight aggregate concrete with pumice stone, silica fume and fly ash as a partial replacement of coarse aggregate. Int J Innov Res Sci Eng Technol 3:18130–18138. https://doi.org/10.15680/IJIRSET.2014.0312051

Tamai H (2015) Enhancing the performance of porous concrete by utilizing the pumice aggregate. Procedia Eng 125:732–738. https://doi.org/10.1016/j.proeng.2015.11.116

Kabay N, Ahmet BK, Mansur TM (2016) Effect of prewetted pumice aggregate addition on concrete properties under different curing conditions. Period Polytech Eng 60:89–95

Anwar Hossain KM (2008) Bond characteristics of plain and deformed bars in lightweight pumice concrete. Constr Build Mater 22:1491–1499. https://doi.org/10.1016/j.conbuildmat.2007.03.025

Campione G, Miraglia N, Papia M (2001) Mechanical properties of steel fibre reinforced lightweight concrete with pumice stone or expanded clay aggregates. Mater Struct Constr 34:201–210. https://doi.org/10.1007/bf02480589

Rajeswari S, Sunilaa G (2016) Experimental study of light weight concrete by partial replacement of coarse aggregate using pumice aggregate. Int J Sci Eng Res 4:50–53

Ji T, Zheng DD, Chen XF, Lin XJ, Wu HC (2015) Effect of prewetting degree of ceramsite on the early-age autogenous shrinkage of lightweight aggregate concrete. Constr Build Mater 98:102–111. https://doi.org/10.1016/j.conbuildmat.2015.08.102

Shigeta A, Ogawa Y, Kawai K (2018) Microscopic investigation on concrete cured internally by using porous ceramic roof-tile waste aggregate. MATEC Web Conf. https://doi.org/10.1051/matecconf/201819501004

Suzuki M, Seddik Meddah M, Sato R (2009) Use of porous ceramic waste aggregates for internal curing of high-performance concrete. Cem Concr Res 39:373–381. https://doi.org/10.1016/j.cemconres.2009.01.007

Sato R, Shigematsu A, Nukushina T, Kimura M (2011) Improvement of properties of portland blast furnace cement type B concrete by internal curing using ceramic roof material waste. J Mater Civ Eng 23:777–782. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000232

Lee NK, Abate SY, Kim HK (2018) Use of recycled aggregates as internal curing agent for alkali-activated slag system. Constr Build Mater 159:286–296. https://doi.org/10.1016/j.conbuildmat.2017.10.110

Yildirim ST, Meyer C, Herfellner S (2015) Effects of internal curing on the strength, drying shrinkage and freeze-thaw resistance of concrete containing recycled concrete aggregates. Constr Build Mater 91:288–296. https://doi.org/10.1016/j.conbuildmat.2015.05.045

Jongvisuttisun P, Leisen J, Kurtis KE (2018) Key mechanisms controlling internal curing performance of natural fibers. Cem Concr Res 107:206–220. https://doi.org/10.1016/j.cemconres.2018.02.007

Kawashima S, Shah S (2011) Early-age autogenous and drying shrinkage behavior of cellulose fiber-reinforced cementitious materials. Cem Concr Compos 33:201–208. https://doi.org/10.1016/j.cemconcomp.2010.10.018

Zanjani V, Bobko C (2014) Nano-mechanical properties of internally cured kenaf fiber reinforced concrete using nanoindentation. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2014.04.002

Mohr B, Premenko L, Nanko H, Kurtis K (2005) Examination of wood-derived powders and fibers for internal curing of cement-based materials. Reference 229–244

Elsaid A, Dawood M, Seracino R, Bobko C (2011) Mechanical properties of kenaf fiber reinforced concrete. Constr Build Mater 25:1991–2001. https://doi.org/10.1016/j.conbuildmat.2010.11.052

Mezencevova A, Garas V, Nanko H, Kurtis K (2012) Influence of thermomechanical pulp fiber compositions on internal curing of cementitious materials. J Mater Civ Eng 24:970–975. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000446

Ning W, Hubbe M, Rojas O, Sunkyu P (2019) Permeation of polyelectrolytes and other solutes into the pore spaces of water-swollen cellulose: a review. BioResources. https://doi.org/10.15376/biores.4.3.1222-1262

Lindstroem T, Carlsson G (1983) The effect of carboxyl groups and their ionic form during drying on the hornification of cellulose fibers. Sven Papperstidning 85:r146–r151

Tu W, Zhu Y, Fang G, Wang X, Zhang M (2019) Internal curing of alkali-activated fly ash-slag pastes using superabsorbent polymer. Cem Concr Res 116:179–190. https://doi.org/10.1016/j.cemconres.2018.11.018

Joudah ZH, Huseien GF, Samadi M, Shukor Lim NHA (2020) Sustainability evaluation of alkali-activated mortars incorporating industrial wastes. Mater Today Proc 46:1971–1977. https://doi.org/10.1016/j.matpr.2021.02.454

Mohammed TA, Kadhim HM (2023) Sustainable high-strength lightweight concrete with pumice stone and sugar molasses. J Mech Behav Mater 32:20220231. https://doi.org/10.1515/jmbm-2022-0231

Mo KH, Ling TC, Alengaram UJ, Yap SP, Yuen CW (2017) Overview of supplementary cementitious materials usage in lightweight aggregate concrete. Constr Build Mater 139:403–418. https://doi.org/10.1016/j.conbuildmat.2017.02.081

Oh S, Choi YC (2018) Superabsorbent polymers as internal curing agents in alkali activated slag mortars. Constr Build Mater 159:1–8. https://doi.org/10.1016/j.conbuildmat.2017.10.121

Choi YC (2022) Hydration and internal curing properties of plant-based natural fiber-reinforced cement composites. Case Stud Constr Mater 17:e01690. https://doi.org/10.1016/j.cscm.2022.e01690

Kim HK, Jang JG, Choi YC, Lee HK (2014) Improved chloride resistance of high-strength concrete amended with coal bottom ash for internal curing. Comput Chem Eng 71:334–343. https://doi.org/10.1016/j.conbuildmat.2014.08.069

Rumšys D, Bačinskas D, Spudulis E, Meškenas A (2017) Comparison of material properties of lightweight concrete with recycled polyethylene and expanded clay aggregates. Procedia Eng 172:937–944. https://doi.org/10.1016/j.proeng.2017.02.105

Ma X, Liu J, Shi C (2019) A review on the use of LWA as an internal curing agent of high performance cement-based materials. Constr Build Mater 218:385–393. https://doi.org/10.1016/j.conbuildmat.2019.05.126

Castro J, la Varga I, Weiss W (2012) Using isothermal calorimetry to assess the water absorbed by fine LWA during mixing. J Mater Civ Eng 24:996–1005. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000496

Hossain KMA, Ahmed S, Lachemi M (2011) Lightweight concrete incorporating pumice based blended cement and aggregate: mechanical and durability characteristics. Constr Build Mater 25:1186–1195. https://doi.org/10.1016/j.conbuildmat.2010.09.036

Balapour M, Zhao W, Garboczi E, Oo NY, Spatari S, Hsuan Y, Billen P, Farnam Y (2019) Potential use of lightweight aggregate (LWA) produced from bottom coal ash for internal curing of concrete systems. Cem Concr Compos 105:103428. https://doi.org/10.1016/j.cemconcomp.2019.103428

Matias D, De Brito J, Rosa A, Pedro D (2013) Mechanical properties of concrete produced with recycled coarse aggregates—influence of the use of superplasticizers. Constr Build Mater 44:101–109. https://doi.org/10.1016/j.conbuildmat.2013.03.011

Dang J, Zhao J, Du Z (2017) Effect of superabsorbent polymer on the properties of concrete. Polymers (Basel) 9:1–17. https://doi.org/10.3390/polym9120672

Piérard J (2006) Mitigating autogenous shrinkage in HPC by internal curing using superabsorbent polymers. pp 97–106. https://doi.org/10.1617/2351580052.011

El-Dieb AS, El-Maaddawy TA, Mahmoud AAM (2012) Water-soluble polymers as selfcuring agents in cement mixes. Adv Cem Res 24:291–299. https://doi.org/10.1680/adcr.11.00030

Kim H-K, Lee H (2016) Autogenous shrinkage reduction with untreated coal bottom ash for high-strength concrete. ACI Mater J. https://doi.org/10.14359/51688700

Yong PC, Teo DCL (2009) Utilisation of recycled aggregate as coarse aggregate in concrete. J Civ Eng Sci Technol 1:1–6. https://doi.org/10.33736/jcest.60.2009

Raoufi K, Schlitter J, Bentz D, Weiss J (2011) Parametric assessment of stress development and cracking in internally cured restrained mortars experiencing autogenous deformations and thermal loading. Adv Civ Eng. https://doi.org/10.1155/2011/870128

Costa H, Júlio E, Lourenço J (2012) New approach for shrinkage prediction of high-strength lightweight aggregate concrete. Constr Build Mater 35:84–91. https://doi.org/10.1016/j.conbuildmat.2012.02.052

Zhutovsky S, Kovler K (2017) Influence of water to cement ratio on the efficiency of internal curing of high-performance concrete. Constr Build Mater 144:311–316. https://doi.org/10.1016/j.conbuildmat.2017.03.203

Hossain T, Salam A, Kader MA (2012) Pervious concrete using brick chips as coarse aggregate: an experimental study. J Civ Eng 40:125–137

Liu F, Wang J, Qian X, Hollingsworth J (2017) Internal curing of high performance concrete using cenospheres. Cem Concr Res 95:39–46. https://doi.org/10.1016/j.cemconres.2017.02.023

Gupta S, Kua HW (2018) Effect of water entrainment by pre-soaked biochar particles on strength and permeability of cement mortar. Constr Build Mater 159:107–125. https://doi.org/10.1016/j.conbuildmat.2017.10.095

Zhang J (2017) Shrinkage of internal cured high strength engineered cementitious composite with pre-wetted sand-like zeolite. Constr Build Mater 134:664–672

Suwan T, Wattanachai P (2017) Properties and internal curing of concrete containing recycled autoclaved aerated lightweight concrete as aggregate. Adv Mater Sci Eng. https://doi.org/10.1155/2017/2394641

Akhnoukh AK (2018) Internal curing of concrete using lightweight aggregates. Part Sci Technol 36:362–367. https://doi.org/10.1080/02726351.2016.1256360

Chen F, Wu K, Ren L, Xu J, Zheng H (2019) Internal curing effect and compressive strength calculation of recycled clay brick aggregate concrete. Materials (Basel). https://doi.org/10.3390/ma12111815

Agostini F, Davy CA, Skoczylas F, Dubois T (2010) Effect of microstructure and curing conditions upon the performance of a mortar added with Treated Sediment Aggregates (TSA). Cem Concr Res 40:1609–1619. https://doi.org/10.1016/j.cemconres.2010.07.003

Memon RP, Sam ARM, Awang AZ, Tahir MM, Mohamed A, Kassim KA, Ismail A (2020) Introducing effective microorganism as self-curing agent in self-cured concrete. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/849/1/012081

Mousa MI, Mahdy MG, Abdel-Reheem AH, Yehia AZ (2015) Mechanical properties of self-curing concrete (SCUC). HBRC J 11:311–320. https://doi.org/10.1016/j.hbrcj.2014.06.004

Ghourchian S, Wyrzykowski M, Lura P, Shekarchi M, Ahmadi B (2013) An investigation on the use of zeolite aggregates for internal curing of concrete. Constr Build Mater 40:135–144. https://doi.org/10.1016/j.conbuildmat.2012.10.009

Jensen OM, Hansen PF (2001) Water-entrained cement-based materials—I. Principles and theoretical background. Cem Concr Res 31:647–654. https://doi.org/10.1016/S0008-8846(01)00463-X

Jensen OM, Hansen PF (2002) Water-entrained cement-based materials: II. Experimental observations. Cem Concr Res 32:973–978. https://doi.org/10.1016/S0008-8846(02)00737-8

Woyciechowski PP, Kalinowski M (2018) The influence of dosing method and material characteristics of superabsorbent polymers (SAP) on the effectiveness of the concrete internal curing. Materials (Basel). https://doi.org/10.3390/ma11091600

Song C, Choi YC, Choi S (2016) Effect of internal curing by superabsorbent polymers—internal relative humidity and autogenous shrinkage of alkali-activated slag mortars. Constr Build Mater 123:198–206. https://doi.org/10.1016/j.conbuildmat.2016.07.007

Liu J, Farzadnia N, Khayat KH, Shi C (2021) Effects of SAP characteristics on internal curing of UHPC matrix. Constr Build Mater 280:122530. https://doi.org/10.1016/j.conbuildmat.2021.122530

Shen D, Liu C, Jiang J, Kang J, Li M (2020) Influence of super absorbent polymers on early-age behavior and tensile creep of internal curing high strength concrete. Constr Build Mater 258:120068. https://doi.org/10.1016/j.conbuildmat.2020.120068

Lei X, Wang R, Jiang H, Xie F, Bao Y (2020) Effect of internal curing with superabsorbent polymers on bond behavior of high-strength concrete. Adv Mater Sci Eng. https://doi.org/10.1155/2020/6651452

Zhutovsky S, Kovler K, Bentur A (2011) Revisiting the protected paste volume concept for internal curing of high-strength concretes. Cem Concr Res 41:981–986. https://doi.org/10.1016/j.cemconres.2011.05.007

Lura P (2003) Autogenous Deformation and Internal Curing of Concrete. DUP Science, pp 1–208

Ding H, Zhang L, Zhang P (2017) factors influencing strength of super absorbent polymer (SAP) concrete. Trans Tianjin Univ 23:245–257. https://doi.org/10.1007/s12209-017-0049-y

Bentur A, Igarashi SI, Kovler K (2001) Prevention of autogenous shrinkage in high-strength concrete by internal curing using wet lightweight aggregates. Cem Concr Res 31:1587–1591. https://doi.org/10.1016/S0008-8846(01)00608-1

Zhuang YZ, Zheng DD, Ng Z, Ji T, Chen XF (2016) Effect of lightweight aggregate type on early-age autogenous shrinkage of concrete. Constr Build Mater 120:373–381. https://doi.org/10.1016/j.conbuildmat.2016.05.105

Sarbapalli D, Dhabalia Y, Sarkar K, Bhattacharjee B (2017) Application of SAP and PEG as curing agents for ordinary cement-based systems: impact on the early age properties of paste and mortar with water-to-cement ratio of 0.4 and above. Eur J Environ Civ Eng 21:1237–1252. https://doi.org/10.1080/19648189.2016.1160843

Kumar M (2013) Preliminary studies of self curing concrete with the addition of polyethylene glycol 1. Assistant Professor, Department of Civil Engineering, vol 2, pp 313–323. www.ijert.org

Amin M, Zeyad AM, Tayeh BA, Saad Agwa I (2021) Engineering properties of self-cured normal and high strength concrete produced using polyethylene glycol and porous ceramic waste as coarse aggregate. Constr Build Mater 299:124243. https://doi.org/10.1016/j.conbuildmat.2021.124243

Zhang Y, Zhu X (2023) Effect of nano-silica on the mechanical performance and microstructure of silicon-aluminum-based internal-cured concrete. J Build Eng 65:105735. https://doi.org/10.1016/j.jobe.2022.105735

Younis MO, Amin M, Tahwia AM (2022) Durability and mechanical characteristics of sustainable self-curing concrete utilizing crushed ceramic and brick wastes. Case Stud Constr Mater 17:e01251. https://doi.org/10.1016/j.cscm.2022.e01251

Alanazi H (2022) Study of the interfacial transition zone characteristics of geopolymer and conventional concretes. Gels. https://doi.org/10.3390/gels8020105

Sun X, Zhang B, Dai Q, Yu X (2015) Investigation of internal curing effects on microstructure and permeability of interface transition zones in cement mortar with SEM imaging, transport simulation and hydration modeling techniques. Constr Build Mater 76:366–379. https://doi.org/10.1016/j.conbuildmat.2014.12.014

Wang F, Yang J, Hu S, Li X, Cheng H (2016) Influence of superabsorbent polymers on the surrounding cement paste. Cem Concr Res 81:112–121. https://doi.org/10.1016/j.cemconres.2015.12.004

Yang J, Wang F, He X, Su Y (2019) Pore structure of affected zone around saturated and large superabsorbent polymers in cement paste. Cem Concr Compos 97:54–67. https://doi.org/10.1016/j.cemconcomp.2018.12.020

Liu J, Farzadnia N, Shi C (2020) Effects of superabsorbent polymer on interfacial transition zone and mechanical properties of ultra-high performance concrete. Constr Build Mater 231:117142. https://doi.org/10.1016/j.conbuildmat.2019.117142

Nie S, Zhang W, Hu S, Liu Z, Wang F (2018) Improving the fluid transport properties of heat-cured concrete by internal curing. Constr Build Mater 168:522–531. https://doi.org/10.1016/j.conbuildmat.2018.02.068

ACI Committee, ACI (308-213) (2015) Report on internally cured concrete using prewetted absorptive lightweight aggregate. Am Concr Inst 28:0–15

Ali JS, Bagchi S, Gupta S (2013) International conference on organised by. Int Conf Innov Civ Eng 4:229–232

Mohanta NR, Murmu M (2022) Alternative coarse aggregate for sustainable and eco-friendly concrete—a review. J Build Eng 59:105079. https://doi.org/10.1016/j.jobe.2022.105079

Safiuddin M, Alengaram UJ, Rahman MM, Salam MA, Jumaat MZ (2013) Use of recycled concrete aggregate in concrete: a review. J Civ Eng Manag 19:796–810. https://doi.org/10.3846/13923730.2013.799093

Xiao J, Li W, Fan Y, Huang X (2012) An overview of study on recycled aggregate concrete in China (1996–2011). Constr Build Mater 31:364–383. https://doi.org/10.1016/j.conbuildmat.2011.12.074

Tabsh SW, Abdelfatah AS (2009) Influence of recycled concrete aggregates on strength properties of concrete. Constr Build Mater 23:1163–1167. https://doi.org/10.1016/j.conbuildmat.2008.06.007

Wyrzykowski M, Ghourchian S, Sinthupinyo S, Chitvoranund N, Chintana T, Lura P (2016) Internal curing of high performance mortars with bottom ash. Cem Concr Compos 71:1–9. https://doi.org/10.1016/j.cemconcomp.2016.04.009

He J, Kawasaki S, Achal V (2020) The utilization of agricultural waste as agro-cement in concrete: a review. Sustainability. https://doi.org/10.3390/SU12176971

Shafigh P, Bin Mahmud H, Jumaat MZ, Zargar M (2014) Agricultural wastes as aggregate in concrete mixtures—a review. Constr Build Mater 53:110–117. https://doi.org/10.1016/j.conbuildmat.2013.11.074

Sudharson G, Kalpana M, Anburaja D, Prathap MG (2021) PEG 400 effect on properties of self curing concrete. IOP Conf Ser Mater Sci Eng 1026:012014. https://doi.org/10.1088/1757-899x/1026/1/012014

Chand MSR, Kumar PR, Giri PSNR, Kumar GR (2018) Performance and microstructure characteristics of self-curing self-compacting concrete. Adv Cem Res 30:451–468. https://doi.org/10.1680/jadcr.17.00154

Shivanshi S, Chakraborti G, Sandesh Upadhyaya K, Kannan N (2023) A study on bacterial self-healing concrete encapsulated in lightweight expanded clay aggregates. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.03.541

Taffese WZ, Nigussie E (2023) Automated concrete curing and assessment of strength and durability using IoT system. Mater Today Proc. https://doi.org/10.1016/j.matpr.2023.07.107

Nilimaa J (2023) Smart materials and technologies for sustainable concrete construction. Dev Built Environ 15:100177. https://doi.org/10.1016/j.dibe.2023.100177

Bashandy AA (2015) Performance of self-curing concrete at elevated temperatures. Indian J Eng Mater Sci 22:93–104

Cortés A, Romate XFS, Jiménez-Suárez A, Campo M, Prolongo MG, Ureña A, Prolongo SG (2020) 3D printed anti-icing and de-icing system based on CNT/GNP doped epoxy composites with self-curing and structural health monitoring capabilities. Smart Mater Struct 30:25016. https://doi.org/10.1088/1361-665X/abd343

Feng D-C, Liu Z-T, Wang X-D, Chen Y, Chang J-Q, Wei D-F, Jiang Z-M (2020) Machine learning-based compressive strength prediction for concrete: an adaptive boosting approach. Constr Build Mater 230:117000. https://doi.org/10.1016/j.conbuildmat.2019.117000

Josserand L, de Larrard F (2004) A method for concrete bleeding measurement. Mater Struct 37:666–670. https://doi.org/10.1007/BF02480511

Kumar EK, Patel SS, Kumar V, Panda SK, Mahmoud SR, Balubaid M (2023) State of art review on applications and mechanism of self-healing materials and structure. Arch Comput Methods Eng 30:1041–1055. https://doi.org/10.1007/s11831-022-09827-3

Dávila-Pompermayer R, Lopez-Yepez LG, Valdez-Tamez P, Juárez CA, Durán-Herrera A (2020) Lechugilla natural fiber as internal curing agent in self compacting concrete (SCC): mechanical properties, shrinkage and durability. Cem Concr Compos 112:103686. https://doi.org/10.1016/j.cemconcomp.2020.103686

Acknowledgements

The authors would like to thank the Research Lab SSVPS BSD COE, Department of Civil Engineering, Kavayitri Bahinabai Chaudhari North Maharashtra University Jalgaon, Maharashtra, India. staff for their support while completing this paper.

Author information

Authors and Affiliations

Contributions

Conceptualization: MNP and Dr. SDD conceived the idea and scope of the review article. They identified the research questions and defined the inclusion and exclusion criteria for selecting relevant literature. Literature Search: MNP conducted the initial literature search, identified appropriate databases, and developed the search strategy. Dr. SDD reviewed the search strategy and made suggestions for additional sources. Article Selection: MNP and Dr. SDD independently screened the articles based on the predefined inclusion and exclusion criteria. Discrepancies were resolved through discussion and consensus. Data Extraction and Analysis: MNP and Dr. SDD extracted relevant data from the selected articles, including study characteristics, methodologies, and key findings. They conducted a qualitative synthesis and identified common themes and patterns in the literature. Writing and Drafting: MNP drafted the initial version of the review article, while Dr. SDD and Dr. HSP contributed to the revision and refinement of the manuscript. Both authors contributed equally to structuring the content, ensuring coherence, and incorporating their respective expertise. Review and Editing: Dr. SDD and Dr. HSP critically reviewed the manuscript, provided feedback on the clarity and organization of the content, and suggested revisions to improve the overall quality. They both contributed to the final editing process. Supervision: Dr. HSP supervised the overall review process, provided guidance on the methodology, and ensured adherence to the research objectives. Dr. SDD provided mentorship and guidance throughout the writing and revision stages. All three authors read and approved the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

Not applicable.

Informed consent

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patil, M.N., Dubey, S.D. & Patil, H.S. Self-curing concrete: a state-of-the-art review. Innov. Infrastruct. Solut. 8, 313 (2023). https://doi.org/10.1007/s41062-023-01282-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01282-8