Abstract

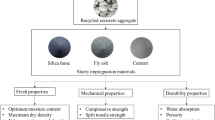

Roller compacted concrete (RCC) is a zero-slump concrete designed for dams and low traffic pavements like parking lots, yards, storage areas etc. The constituents of RCC are similar to conventional concrete but aggregate content is higher, about 10% by volume. Due to the scarcity of natural aggregates, recycled asphalt pavement aggregates (RAP) are used to replace partially or fully the natural aggregates. Literature suggests that RAP inclusion in concrete leads to reduced mechanical properties due to weak interfacial transition zone (ITZ) but also hints about using measures like supplementary cementitious materials to improve these properties. Most of the studies follow one or the other aggregate gradation and aggregate size which definitely alters the properties from one study to the other. So, in this study, a mix design methodology was developed for roller compacted concrete (RCC) by altering the mix design composition of pavement quality concrete (PQC) conforming to IRC: 44, followed by natural aggregate substitution with 50% RAP aggregates by volume, and addition of fly ash (30%) and silica fume (15%) to improve the interphase of paste-aggregate For suitability of the developed mix proportions for pavement applications, its mechanical properties, abrasion and durability were evaluated. Results showed that addition of RAP reduced the compressive and flexural strength in RCC mixes by 24% and 14%, in comparison to the control RCC due to inferior bonding between asphalt coated RAP aggregates and cement paste. Addition of silica fume improved the compressive and flexural strength of RCC–RAP mix values by 9% (32.8 MPa) and 5.5% (3.9 MPa) but the strength values still remain poorer than control RCC. Durability on the other hand improves with the addition of RAP aggregates and it improves further with the addition of SCMs. Porosity and sorptivity decreased by 5.5% and 36.11% respectively, whereas water absorption increased by 3.36% by incorporation of 50% RAP in RCC. Subsequent SCMs addition to RAP–RCC decreased the porosity, sorptivity and water absorption by 28.92%, 55.55% and 20.5%, respectively with respect to control RCC. Considering a minor decrease in strength (< 10%) and a high improvement in durability and abrasion resistance, it is recommended that such concrete pavements can be used for rural roads. In addition, this article proves that RCC could yield a better correlation between destructive and non-destructive tests, and thus is reliable for casting at site.

Similar content being viewed by others

References

Harrington D, Abdo F, Adaska W, Hazaree C, Ceylan H (2010) Ceylan, Guide for roller-compacted concrete pavements

Deghfel M, Meddah A, Beddar M, Chikouche MA (2019) Experimental study on the effect of hot climate on the performance of roller-compacted concrete pavement, innovative Infrastructure. Solutions 4:1–12. https://doi.org/10.1007/s41062-019-0246-8

Harrington D, Abdo F, Adaska W, Hazaree C (2010) Guide for roller-compacted concrete pavements, In: Trans project reports institute for transportation. http://lib.dr.iastate.edu/intrans_reports

TIFAC, Technology Information, Forecasting and Assessment Council (2001). www.tifac.org.in

Dong Q, Huang B (2014) Laboratory evaluation on resilient modulus and rate dependencies of RAP used as unbound base material. J Mater Civ Eng 26:379–383. https://doi.org/10.1061/(asce)mt.1943-5533.0000820

Devulapalli L, Kothandaraman S, Sarang G (2021) Fracture characterization of stone matrix asphalt mixtures incorporating reclaimed asphalt pavement and rejuvenator. J Mater Civ Eng 33:1–13. https://doi.org/10.1061/(asce)mt.1943-5533.0003945

Debbarma S, Ransinchung GD (2021) Achieving sustainability in roller compacted concrete pavement mixes using reclaimed asphalt pavement aggregates: state of the art review. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.125078

Debbarma S, Ransinchung GDRN, Singh S (2019) Feasibility of roller compacted concrete pavement containing different fractions of reclaimed asphalt pavement. Constr Build Mater 199:508–525

Settari C, Debieb F, Hadj E, Boukendakdji O (2015) Assessing the effects of recycled asphalt pavement materials on the performance of roller compacted concrete. Constr Build Mater 101:617–621. https://doi.org/10.1016/j.conbuildmat.2015.10.039

Modarres A, Hosseini Z (2014) Mechanical properties of roller compacted concrete containing rice husk ash with original and recycled asphalt pavement material. Mater Des 64:227–236. https://doi.org/10.1016/j.matdes.2014.07.072

Debbarma S, Ransinchung GD, Singh S, Sahdeo S (2020) Utilization of industrial and agricultural wastes for productions of sustainable roller compacted concrete pavement mixes containing reclaimed asphalt pavement aggregates. Resour Conserv Recycl 152:104504. https://doi.org/10.1016/j.resconrec.2019.104504

Bilodeau C, Sauzeat K, Di Benedetto H, Olard F (2012) Roller compacted concrete for road base layer with RAP and steel fibers: viscous properties and description of experimental sites. In: 10th international conference on concrete pavements: Québec City, pp 435–448

Bilodeau H, Sauzeat C, Di Benedetto H, Olard F, Bonneau D (2011) Laboratory and in situ investigations of steel fiber-reinforced compacted concrete containing reclaimed asphalt pavement. In: Transportation research board 90th annual meeting, Washington DC

Fakhri M, Amoosoltani E (2017) The effect of reclaimed asphalt pavement and crumb rubber on mechanical properties of roller compacted concrete pavement. Constr Build Mater 137:470–484. https://doi.org/10.1016/j.conbuildmat.2017.01.136

Singh S, Ransinchung GDRN, Debbarma S, Kumar P (2017) Utilization of reclaimed asphalt pavement aggregates containing waste from sugarcane mill for production of concrete mixes. J Clean Prod. https://doi.org/10.1016/j.jclepro.2017.10.179

Debbarma S, Singh S, Ransinchung GDRN (2019) Laboratory investigation on the fresh, mechanical, and durability properties of roller compacted concrete pavement containing reclaimed asphalt pavement aggregates. Transp Res Record. https://doi.org/10.1177/0361198119849585

Brand AS, Roesler JR (2017) Bonding in cementitious materials with asphalt-coated particles: part II—cement-asphalt chemical interactions. Constr Build Mater 130:182–192. https://doi.org/10.1016/j.conbuildmat.2016.10.013

Brand AS, Roesler JR (2017) Bonding in cementitious materials with asphalt-coated particles: part I—the interfacial transition zone. Constr Build Mater 130:171–181. https://doi.org/10.1016/j.conbuildmat.2016.10.019

Debbarma S, Ransinchung GDRN, Singh S, Kant S (2020) Utilization of industrial and agricultural wastes for productions of sustainable roller compacted concrete pavement mixes containing reclaimed asphalt pavement aggregates. Resour Conserv Recycl 152:104504

Singh S, Ransinchung GD, Kumar P (2017) Feasibility study of RAP aggregates in cement concrete pavements. Road Mater Pavement Des 20(1):151–170. https://doi.org/10.1080/14680629.2017.1380071

Aladegboye OJ, Oguntayo OD, Al-Ihekwaba E, Daniel TE, Chiadighikaobi PC, Ngandu P (2022) Evaluation of volumetric properties of cassava peel ash modified asphalt mixtures. Civil Eng J (Iran) 8:2110–2124. https://doi.org/10.28991/CEJ-2022-08-10-07

Balamuralikrishnan R, Saravanan J (2021) Effect of addition of alccofine on the compressive strength of cement mortar cubes. Emerg Sci J 5(2):155–170

Siddique R (2011) Utilization of silica fume in concrete: review of hardened properties. Resour Conserv Recycl 55:923–932. https://doi.org/10.1016/j.resconrec.2011.06.012

Siddique R, Chahal N (2011) Use of silicon and ferrosilicon industry by-products (silica fume) in cement paste and mortar. Resour Conserv Recycl 55:739–744. https://doi.org/10.1016/j.resconrec.2011.03.004

Singh S, Ransinchung GD, Kumar P (2017) Effect of mineral admixtures on fresh, mechanical and durability properties of RAP inclusive concrete. Constr Build Mater 156:19–27. https://doi.org/10.1016/j.conbuildmat.2017.08.144

Abolfazl Hassani MA (2010) Enhancement of concrete properties for pavement slabs using waste metal drillings and silica fume. Waste Manag Res 28:56–63. https://doi.org/10.1177/0734242x09104143

Debbarma S, Ransinchung GD, Dhaka M (2020) Effects of a Portland cement additive rich in SiO2 and Al2O3 in microstructure densification of RAP incorporated RCCP mixes. Constr Build Mater 258:7–14. https://doi.org/10.1016/j.conbuildmat.2020.119626

Atiş CD, Sevim UK, Özcan F, Bilim C, Karahan O, Tanrikulu AH, Ekşi A (2004) Strength properties of roller compacted concrete containing a non-standard high calcium fly ash. Mater Lett 58:1446–1450. https://doi.org/10.1016/j.matlet.2003.10.007

Debbarma S, Ransinchung GD, Singh S (2021) Suitability of various supplementary cementitious admixtures for RAP inclusive RCCP mixes. Int J Pavement Eng 22:1568–1581. https://doi.org/10.1080/10298436.2019.1703981

Ahmadi M, Shafabakhsh GA, Di Mascio P, Hassani A (2021) Failure behavior of functionally graded roller compacted concrete pavement under mode I and III fracture. Constr Build Mater 307:124942. https://doi.org/10.1016/j.conbuildmat.2021.124942

IS: 8112 (2013) Ordinary Portland Cement, 43 Grade: Specification

IS: 383 (2016) Indian standard specification for coarse and fine aggregate from natural sources for concrete

IRC: 44-2017 (2017) Guidelines for cement concrete mix design for pavements indian roads congress, Bureau of Indian Standards, New Dehli, pp 44–2017

Junaid M, Shah MZA, Yaseen G, Awan HH, Khan D, Jawad M (2022) Investigating the effect of gradation, temperature and loading duration on the resilient modulus of asphalt concrete. Civil Eng J (Iran) 8:278–289. https://doi.org/10.28991/CEJ-2022-08-02-07

IS 2720-7 (1980) Methods of tests for soils,Part 7:Determination of water content -dry density relation using light compaction

Debbarma S, Ransinchung GDRN, Singh S, Debbarma S (2019) Suitability of various supplementary cementitious admixtures for RAP inclusive RCCP mixes mixes. Int J Pavement Eng ISSN 22:1568–1581. https://doi.org/10.1080/10298436.2019.1703981

Nanni A (1988) curing of roller compacted concrete: strength development. J Transp Eng 114:684–694

IS:516 (2014) Methods of tests for strength of concrete

A. C1747/C1747M, (American Society for Testing and Materials) (2013) Standard test method for determining potential resistance to degradation of pervious concrete by impact and abrasion

A. C642 (2013) Standard Test method for density, absorption and voids in hardened concrete

A. C 1585, ASTM (American Society for Testing and Materials) (2013) Standard test method for measurement of rate of absorption of water by hydraulic-cement concretes

AASHTO TP 95 (2014) Standard test method for surface resistivity of concrete’s ability to resist chloride ion penetration

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

This research was performed in accordance with the ethical standards of the institutional and/or research committee and with the 1964 Helsinki declaration and its later amendments or com- parable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, P., Sharma, S.K., Rambabu, D. et al. A detailed laboratory investigation on evolving the mix design of roller compacted concrete containing RAP aggregates and SCMs. Innov. Infrastruct. Solut. 8, 284 (2023). https://doi.org/10.1007/s41062-023-01248-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01248-w