Abstract

This paper aimed to study the effect of coir fibres and cement inclusion on the physico–mechanical, durability and strength properties of hollow interlocking compressed earth blocks (ICEBs). The effect of moisture content on block strength at the time of testing was also considered. In total twenty different types of blocks were prepared with cement contents (0% and 10%), fibre contents (0%, 0.3%, 0.6% and 0.9% by dry weight of soil) and lengths (30 mm, 50 mm and 70 mm). The blocks were tested in air-dry as well as in wet states. Scanning electron microscopy (SEM) analysis was made to know the microstructure of coir fibres and blocks. Also, correlations between mechanical properties were established. Furthermore, empirical models were derived for estimating the strength properties. Test results show that addition of 10% cement slightly increases the bulk density (ρ), substantially improves strength properties and remarkably decreases linear drying shrinkage (LDS). The inclusion of coir fibres to both ICEBs (unstabilized) and ICSEBs (stabilized) significantly reduces the bulk density (ρ), ultrasonic pulse velocity (UPV), and LDS, and increases the water absorption (WA). Addition of coir fibres significantly improves the mechanical strength of both types of blocks. Blocks reinforced with 0.6% fibre and 50 mm length possesses higher compressive, flexural and splitting tensile strength. The optimum fibre content and length were found to be 0.6% and 50 mm, respectively. On the other hand, higher fibre content (0.9%) and length (70 mm) adversely affected the strength and increases water absorption for all types of blocks. UPV test appeared to be ineffective in estimating the strength of ICSEBs when the reinforcing fibre content increases due to the presence of larger amount of air voids. A good linear relationship was obtained between the mechanical properties for the block types. The proposed models can be adopted to estimate the block strengths with reasonable accuracy.

Similar content being viewed by others

Abbreviations

- CEB:

-

Compressed earth block

- CSEB:

-

Compressed stabilized earth block

- C :

-

Cement content

- F c :

-

Fibre content

- F l :

-

Fibre length

- F :

-

Fibre reinforced

- FICEB:

-

Fibre-reinforced hollow interlocking compressed earth block

- FICSEB:

-

Fibre-reinforced hollow interlocking compressed cement stabilized earth block

- f cs :

-

Compressive strength

- f cs- air dry :

-

Air-dry compressive strength

- f cs-wet :

-

Wet compressive strength

- f b :

-

Flexural strength

- f b-air dry :

-

Air-dry flexural strength

- f b-wet :

-

Wet flexural strength

- f t :

-

Splitting tensile strength

- f t-air dry :

-

Air-dry splitting tensile strength

- f t-wet :

-

Wet splitting tensile strength

- GSD:

-

Grain size distribution

- ICEB:

-

Hollow interlocking compressed earth block

- ICSEB:

-

Hollow interlocking compressed stabilized earth block

- l :

-

Length of ultrasonic pulse through the block

- L 1 :

-

Length of block after 24 h of production

- L 2 :

-

Length of block after completion of curing and oven drying

- LDS:

-

Linear drying shrinkage

- MDD:

-

Maximum dry density

- MLRA:

-

Multi-linear regression analysis

- OMC:

-

Optimum moisture content

- RE:

-

Rammed earth

- SEM:

-

Scanning electron microscopy

- t :

-

Pulse transition time

- UPV:

-

Ultrasonic pulse velocity

- UPVx :

-

Ultrasonic pulse velocity parallel to wall bed joint

- UPVy :

-

Ultrasonic pulse velocity perpendicular to wall bed joint

- UPVz :

-

Ultrasonic pulse velocity parallel to wall thickness

- UTM:

-

Universal testing machine

- W:

-

Water content

- WA:

-

Water absorption

- W wet :

-

Weight of block after immersed in water

- W oven :

-

Weight of block before immersion

- ρ :

-

Bulk density

- ρ d :

-

Dry density

References

Walker P (2002) HB 195-2002 The Australian earth building handbook. Stand. Aust. Int., Sydney, pp 1–163

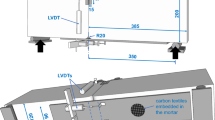

Kasinikota P, Tripura DD (2021) Prediction of physical-mechanical properties of hollow interlocking compressed unstabilized and stabilized earth blocks at different moisture conditions using ultrasonic pulse velocity. J Build Eng 48:103961. https://doi.org/10.1016/j.jobe.2021.103961

Reddy BVV, Gupta A (2005) Characteristics of soil-cement blocks using highly sandy soils. Mater Constr 38:651. https://doi.org/10.1617/14265

Reddy BVV, Lal R, Nanjunda Rao KS (2007) Optimum soil grading for the soil-cement blocks. J Mater Civ Eng 19:139–148. https://doi.org/10.1061/(asce)0899-1561(2007)19:2(139)

Nagaraj HB, Rajesh A, Sravan MV (2016) Influence of soil gradation, proportion and combination of admixtures on the properties and durability of CSEBs. Constr Build Mater 110:135–144. https://doi.org/10.1016/j.conbuildmat.2016.02.023

Zak P, Ashour T, Korjenic A et al (2016) The influence of natural reinforcement fibers, gypsum and cement on compressive strength of earth bricks materials. Constr Build Mater 106:179–188. https://doi.org/10.1016/j.conbuildmat.2015.12.031

Zare P, Sheikhi Narani S, Abbaspour M et al (2020) Experimental investigation of non-stabilized and cement-stabilized rammed earth reinforcement by waste tire textile fibers (WTTFs). Constr Build Mater 260:120432. https://doi.org/10.1016/j.conbuildmat.2020.120432

Sore O, Messan S, Prud’homme A, et al (2018) Stabilization of compressed earth blocks (CEBs) by geopolymer binder based on local materials from Burkina Faso. Constr Build Mater 165:333–345. https://doi.org/10.1016/j.conbuildmat.2018.01.051

Dabakuyo I, Mutuku RNN, Onchiri RO (2022) Mechanical properties of compressed earth block stabilized with sugarcane molasses and metakaolin-based geopolymer. Civ Eng J 8:780–795

Narayanaswamy AH, Walker P, Venkatarama Reddy BV et al (2020) Mechanical and thermal properties, and comparative life-cycle impacts, of stabilised earth building products. Constr Build Mater 243:118096. https://doi.org/10.1016/j.conbuildmat.2020.118096

Rao KVM, Reddy BVV, Jagadish KS (1996) Flexural bond strength of masonry using various blocks and mortars. Mater Struct 29:119–124. https://doi.org/10.1007/bf02486202

Weed DA, Tennant AG, Motamedi MH et al (2020) Finite element model application to flexural behavior of cement stabilized soil block masonry. Mater Struct 53:1–20. https://doi.org/10.1617/s11527-020-01490-z

Reddy BVV, Latha MS (2018) Mortar shrinkage and flexure bond strength of stabilized soil brick masonry. J Mater Civ Eng. https://doi.org/10.1061/(asce)mt.1943-5533.0002280

Taallah B, Guettala A, Guettala S, Kriker A (2014) Mechanical properties and hygroscopicity behavior of compressed earth block filled by date palm fibers. Constr Build Mater 59:161–168. https://doi.org/10.1016/j.conbuildmat.2014.02.058

Taallah B, Guettala A (2016) The mechanical and physical properties of compressed earth block stabilized with lime and filled with untreated and alkali-treated date palm fibers. Constr Build Mater 104:52–62. https://doi.org/10.1016/j.conbuildmat.2015.12.007

Khedari J, Watsanasathaporn P, Hirunlabh J (2005) Development of fibre-based soil-cement block with low thermal conductivity. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2004.02.042

Danso H, Martinson DB, Ali M, Williams J (2015) Effect of fibre aspect ratio on mechanical properties of soil building blocks. Constr Build Mater 83:314–319. https://doi.org/10.1016/j.conbuildmat.2015.03.039

Millogo Y, Morel JC, Aubert JE, Ghavami K (2014) Experimental analysis of pressed adobe blocks reinforced with hibiscus cannabinus fibers. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2013.10.094

Rathod RSB, Reddy BVV (2021) Strength and stress–strain characteristics of fibre reinforced cement stabilised rammed earth. Mater Struct 54:6–10. https://doi.org/10.1617/s11527-021-01640-x

Donkor P, Obonyo E (2015) Earthen construction materials: assessing the feasibility of improving strength and deformability of compressed earth blocks using polypropylene fibers. Mater Des. https://doi.org/10.1016/j.matdes.2015.06.017

Hejazi SM, Sheikhzadeh M, Abtahi SM, Zadhoush A (2012) A simple review of soil reinforcement by using natural and synthetic fibers. Constr Build Mater 30:100–116. https://doi.org/10.1016/j.conbuildmat.2011.11.045

Ghavami K, Toledo Filho RD, Barbosa NP (1999) Behaviour of composite soil reinforced with natural fibres. Cem Concr Compos. https://doi.org/10.1016/S0958-9465(98)00033-X

Toledo Filho R, Scrivener K, England GL, Ghavami K (2000) Durability of alkali-sensitive sisal and coconut fibres in cement. Cem Concr Compos 22:127–143

Munawar SS, Umemura K, Kawai S (2007) Characterization of the morphological, physical, and mechanical properties of seven nonwood plant fiber bundles. J Wood Sci 53:108–113. https://doi.org/10.1007/s10086-006-0836-x

Ramakrishna G, Sundararajan T (2005) Studies on the durability of natural fibres and the effect of corroded fibres on the strength of mortar. Cem Concr Compos 27:575–582. https://doi.org/10.1016/j.cemconcomp.2004.09.008

Ali M, Liu A, Sou H, Chouw N (2012) Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr Build Mater 30:814–825. https://doi.org/10.1016/j.conbuildmat.2011.12.068

Danso H, Martinson DB, Ali M, Williams JB (2015) Physical, mechanical and durability properties of soil building blocks reinforced with natural fibres. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2015.10.069

Thanushan K, Yogananth Y, Sangeeth P (2019) Strength and durability characteristics of coconut fibre reinforced earth cement blocks. J Nat Fibers. https://doi.org/10.1080/15440478.2019.1652220

Sai S, Raavi D, Tripura DD (2020) Predicting and evaluating the engineering properties of unstabilized and cement stabilized fibre reinforced rammed earth blocks. Constr Build Mater 262:120845. https://doi.org/10.1016/j.conbuildmat.2020.120845

Heathcote K, Jankulovski E (1993) Relationship between moisture content and strength of soilcrete blocks: results of experimental investigation into relationship between moisture content and compressive strength of cement-stabilized soilcrete blocks. Build Res Inf 21:103–108. https://doi.org/10.1080/09613219308727269

Sangma S, Pohti L, Tripura DD (2019) Size effect of fiber on mechanical properties of mud earth blocks. Springer Singapore

Indian Standard (1980) Methods of test for soils: determination of specific gravity. IS 2720 (part 3), New Delhi, India

Indian Standard (1983) Determination of water content-dry density relation using heavy compaction. IS 2720 (Part 8), New Delhi, India

Indian Standard (1985) Methods of test for soils: grain size analysis. IS 2720 (Part 4), New Delhi, India

Indian Standard (1985) Methods of test for soils: determination of liquid limit and plastic limit. IS 2720 (Part 5), New Delhi, India

Indian Standard (2013) Specification for 43 grade ordinary portland cement. IS 8112, New Delhi, India

Balamuralikrishnan R, Saravanan J (2021) Effect of addition of alccofine on the compressive strength of cement mortar cubes. Emerg Sci J 5:155–170

Kasinikota P, Tripura DD (2022) Flexural behavior of hollow interlocking compressed stabilized earth-block masonry walls under out-of-plane loading. J Build Eng 57:104895. https://doi.org/10.1016/j.jobe.2022.104895

Jannat N, Hussien A, Abdullah B, Cotgrave A (2020) Application of agro and non-agro waste materials for unfired earth blocks construction: a review. Constr Build Mater 254:119346. https://doi.org/10.1016/j.conbuildmat.2020.119346

Walker PJ (2004) Strength and erosion characteristics of earth blocks and earth block masonry. J Mater Civ Eng 16:497–506. https://doi.org/10.1061/0899-1561(2004)16:5(497)

Cottrell JA, Ali M, Tatari A, Martinson DB (2021) An investigation into the influence of geometry on compressed earth building blocks using finite element analysis. Constr Build Mater 273:121997. https://doi.org/10.1016/j.conbuildmat.2020.121997

Islam MS, Tausif-E-Elahi SAR et al (2020) Strength and durability characteristics of cement-sand stabilized earth blocks. J Mater Civ Eng 32:04020087. https://doi.org/10.1061/(asce)mt.1943-5533.0003176

Elahi TE, Shahriar AR, Islam MS et al (2020) Suitability of fly ash and cement for fabrication of compressed stabilized earth blocks. Constr Build Mater 263:120935. https://doi.org/10.1016/j.conbuildmat.2020.120935

Latha MS, Venkatarama Reddy BV (2017) Swell–shrink properties of stabilised earth products. Proc Instit Civ Eng Constr Mater 170(1):3–15

Lanzón M, Martínez E, Mestre M, Madrid JA (2017) Use of zinc stearate to produce highly-hydrophobic adobe materials with extended durability to water and acid-rain. Constr Build Mater 139:114–122. https://doi.org/10.1016/j.conbuildmat.2017.02.055

Indian Standard. (1992) IS 13311-1 (1992): method of non-destructive testing of concret, Part 1: ultrasonic pulse velocity. IS 13311 (Part 1), New Delhi, India 1–7

Kadhim NR, Hussain WAM, Abdulrasool AT, Azeez MA (2022) The Influence of nanoclay and powdered ceramic on the mechanical properties of mortar. Civ Eng J 8:1435–1446

Indian Standard (1974) Methods of test for stabilized soils. Determination of unconfined compressive strength of stabilized soils. IS 4332 (Part 4), New Delhi, India 11:76

Indian Standard. (1999) Indian standard Splitting tensile strength of concrete- method of test (first revision). IS 5816, New Delhi, India 1–14

Masuka S, Gwenzi W, Rukuni T (2018) Development, engineering properties and potential applications of unfired earth bricks reinforced by coal fly ash, lime and wood aggregates. J Build Eng 18:312–320. https://doi.org/10.1016/j.jobe.2018.03.010

Bruno AW, Gallipoli D, Perlot C, Kallel H (2020) Thermal performance of fired and unfired earth bricks walls. J Build Eng. https://doi.org/10.1016/j.jobe.2019.101017

Khoudja D, Taallah B, Izemmouren O et al (2021) Mechanical and thermophysical properties of raw earth bricks incorporating date palm waste. Constr Build Mater 270:121824. https://doi.org/10.1016/j.conbuildmat.2020.121824

Bouhicha M, Aouissi F, Kenai S (2005) Performance of composite soil reinforced with barley straw. Cem Concr Compos 27(5):617–621

Wang L, He T, Zhou Y et al (2021) The influence of fiber type and length on the cracking resistance, durability and pore structure of face slab concrete. Constr Build Mater 282:122706. https://doi.org/10.1016/j.conbuildmat.2021.122706

Indian Standard (2013) Stabilized soil blocks used in general building construction-specification. IS 1725, New Delhi, India

Araya-Letelier G, Antico FC, Burbano-Garcia C et al (2021) Experimental evaluation of adobe mixtures reinforced with jute fibers. Constr Build Mater 276:122127. https://doi.org/10.1016/j.conbuildmat.2020.122127

Aldaood A, Khalil A, Bouasker M, AL-Mukhtar M (2021) Experimental study on the mechanical behavior of cemented soil reinforced with straw fiber. Geotech Geol Eng 39:2985–3001. https://doi.org/10.1007/s10706-020-01673-z

Carrasco EVM, Silva SR, Mantilla JNR (2014) Assessment of mechanical properties and the influence of the addition of sawdust in soil-cement bricks using the technique of ultrasonic anisotropic inspection. J Mater Civ Eng 26:219–225. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000723

Araya-Letelier G, Concha-Riedel J, Antico FC et al (2018) Influence of natural fiber dosage and length on adobe mixes damage-mechanical behavior. Constr Build Mater 174:645–655. https://doi.org/10.1016/j.conbuildmat.2018.04.151

Bahar R, Benazzoug M, Kenai S (2004) Performance of compacted cement-stabilised soil. Cem Concr Compos 26:811–820. https://doi.org/10.1016/j.cemconcomp.2004.01.003

Tang C, Shi B, Gao W et al (2007) Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext Geomembr 25:194–202. https://doi.org/10.1016/j.geotexmem.2006.11.002

Namango S (2016) Development of cost-effective earthen building material for housing wall construction development of cost-effective earthen building material for housing wall construction: investigations into the properties of compressed earth blocks stabilized with sis

Kasinikota P, Tripura DD (2021) Predicting the effect of crushed brick particle size on anisotropy, physical and mechanical properties of compressed stabilized earth blocks using ultrasonic pulse velocity. Mater Struct. https://doi.org/10.1617/s11527-021-01712-y

Walker PJ (1995) Strength, durability and shrinkage characteristics of cement stabilised soil blocks. Cem Concr Compos 17:301–310. https://doi.org/10.1016/0958-9465(95)00019-9

Heathcote KA (1995) Durability of earthwall buildings. Constr Build Mater 9:185–189

Al-hadithi AI, Hilal NN (2016) The possibility of enhancing some properties of self-compacting concrete by adding waste plastic fi bers. J Build Eng 8:20–28. https://doi.org/10.1016/j.jobe.2016.06.011

Villamizar MCN, Araque VS, Reyes CAR, Silva RS (2012) Effect of the addition of coal-ash and cassava peels on the engineering properties of compressed earth blocks. Constr Build Mater 36:276–286. https://doi.org/10.1016/j.conbuildmat.2012.04.056

NZS 4298 (1998) Materials and workmanship for earth buildings. Stand New Zeal

Tran KQ, Satomi T, Takahashi H (2018) Improvement of mechanical behavior of cemented soil reinforced with waste cornsilk fibers. Constr Build Mater 178:204–210. https://doi.org/10.1016/j.conbuildmat.2018.05.104

Hallal MM, Sadek S, Najjar SS (2018) Evaluation of engineering characteristics of stabilized rammed-earth material sourced from natural fines-rich soil. J Mater Civ Eng 30:04018273. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002481

Raavi SSD, Tripura DD (2020) Predicting and evaluating the engineering properties of unstabilized and cement stabilized fibre reinforced rammed earth blocks. Constr Build Mater 262:120845. https://doi.org/10.1016/j.conbuildmat.2020.120845

Yadav JS, Tiwari SK (2017) Effect of waste rubber fibres on the geotechnical properties of clay stabilized with cement. Appl Clay Sci 149:97–110. https://doi.org/10.1016/j.clay.2017.07.037

Salih MM, Osofero AI, Imbabi MS (2020) Constitutive models for fibre reinforced soil bricks. Constr Build Mater 240:117806. https://doi.org/10.1016/j.conbuildmat.2019.117806

NZS 4297 (2004) Engineering design of earth buildings. Stand, New Zealand

Silveira D, Varum H, Costa A (2013) Influence of the testing procedures in the mechanical characterization of adobe bricks. Constr Build Mater 40:719–728. https://doi.org/10.1016/j.conbuildmat.2012.11.058

Abdellatief M, Abd M, Elgendy G et al (2023) Response surface methodology-based modelling and optimization of sustainable UHPC containing ultrafine fly ash and metakaolin. Constr Build Mater 388:131696. https://doi.org/10.1016/j.conbuildmat.2023.131696

Abdellatief M, Al-tam SM, Elemam WE, Alanazi H (2023) Case studies in construction materials development of ultra-high-performance concrete with low environmental impact integrated with metakaolin and industrial wastes. Case Stud Constr Mater 18:e01724. https://doi.org/10.1016/j.cscm.2022.e01724

Nematzadeh M, Naghipour M (2012) Compressive strength and modulus of elasticity of freshly compressed concrete. Constr Build Mater 34:476–485

Sinsiri T, Teeramit P, Kiattikomol K (2006) Effect of finenesses of fly ash on expansion of mortars in magnesium sulfate T1. Sci Asia 32:63–69. https://doi.org/10.2306/scienceasia1513-1874.2006.32.63

Wang X, Yuan J, Wei P, Zhu M (2019) Effects of fly ash microspheres on sulfate erosion resistance and chlorion penetration resistance in concrete. J Therm Anal Calorim. https://doi.org/10.1007/s10973-019-08705-8

Haustein E, Kuryłowicz-Cudowska A (2020) The effect of fly ash microspheres on the pore structure of concrete. Minerals 10(1):58

Nayak CB, Taware PP, Jagadale UT et al (2021) Effect ofSiO2 and ZnO Nano—composites on mechanical and chemical properties of modified concrete. Iran J Sci Technol Trans Civ Eng. https://doi.org/10.1007/s40996-021-00694-9

Kate GK, Nayak CB, Thakare SB (2021) Optimization of sustainable high–strength–high–volume fly ash concrete with and without steel fiber using Taguchi method and multi-regression analysis. Innov Infrastruct Solut 6:1–18. https://doi.org/10.1007/s41062-021-00472-6

Zanjad N, Pawar S, Nayak C (2022) Use of fly ash cenosphere in the construction industry: a review materials today: proceedings use of fly ash cenosphere in the construction industry: a review. Mater Today Proc. https://doi.org/10.1016/j.matpr.2022.03.362

Kumar A, Supriya R (2022) State of the art review on physiochemical and engineering characteristics of fly ash and its applications. Int J Coal Sci Technol. https://doi.org/10.1007/s40789-022-00472-6

Bengal SN, Pammar LS, Nayak CB (2022) Engineering application of organic materials with concrete: a review materials today: proceedings engineering application of organic materials with concrete: a review. Mater Today Proc. https://doi.org/10.1016/j.matpr.2022.02.390

Funding

This work was supported by Science and Engineering Research Board (SERB), Grant no. EEQ/2017/000001, Department of Science and Technology, Government of India.

Author information

Authors and Affiliations

Contributions

KP contributed to conceptualization, formal analysis, investigation, methodology, validation, and writing – original draft. DDT contributed to supervision, visualization, resources, and writing – review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

The study reported in this article is part of the first author’s published Doctoral Thesis, at the National Institute of Technology Agartala. The content of this work has not been published or submitted to any other journal for consideration.

Informed consent

Not applicable

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kasinikota, P., Tripura, D.D. Effects of coir fibres and cement addition on properties of hollow interlocking compressed earth blocks. Innov. Infrastruct. Solut. 8, 273 (2023). https://doi.org/10.1007/s41062-023-01240-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01240-4