Abstract

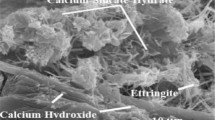

The concept of self-curing for improving the resistance of concrete to shrinkage cracks and strength in concrete is used from last many years. But a systematic review of material used as self-curing agents was lacking. This study presents a review on various self-curing agents used over ages for application in concrete. A comparison of mechanisms of external curing with internal curing, supported by sketches and microscopic images has been made. This paper reviews different self-curing agents considering properties such as particle size, water absorption, water desorption, and relative density. Thereby classifying different self-curing agents on the basis of nature into three categories, viz physical, chemical, and biological. This study also presents the characteristics of self-curing agents and their effects on concrete as determined by the nature of the agents. On the basis of review, it was found that use of internal curing agents led to reduction in autogenous shrinkage and improvement in mechanical and durability behavior of concrete in addition to relevant environmental and economic benefits.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study if any are available from the corresponding author on reasonable request.

Abbreviations

- IC:

-

Internal curing

- LWA:

-

Lightweight aggregates

- PFLWA:

-

Pre-wetted fine lightweight aggregates

- ICC:

-

Internally cured concrete

- FA:

-

Fine aggregate

- RH:

-

Relative humidity

- C:

-

Cement

- CA:

-

Coarse aggregates

- W:

-

Water

- Ad.:

-

Admixtures

- HPC:

-

High-performance concrete

- GGBFS:

-

Ground-granulated blast-furnace slag

- LECA:

-

Light expanded clay aggregate

- UHPC:

-

Ultrahigh-performance concrete

- SEM:

-

Scanning electron microscope

- LWD:

-

Air-dried lightweight aggregates

- SAP:

-

Super absorbent polymer

- LWW:

-

Lightweight wet aggregates

- XRD:

-

X-ray diffraction

- TGA:

-

Thermogravimetric analyzer

- MIP:

-

Mercury intrusion porosimetry

- XCT:

-

X-ray-computed micro-tomography

References

ACI 308.1-98 (1998) Standard specification for curing concrete. ACI Committee 308, pp 1–9

Bentz, D. P. and Weiss, W. J. (2011) ‘Internal Curing : A 2010 State-of-the- Art Review’, Civil Engineering.

Bremner TW, Ries J (2009) Stephen J. Hayde: father of the lightweight concrete industry. Concr Int 31(8):35–38

Klieger P (1957) Long-time study of cement performance in concrete Chapter 10-progress report on strength and elastic properties of concrete. J Proc 54(12):481–504. https://doi.org/10.14359/11452

Philleo R (1991) Concrete science and reality. Mater Sci Concr pp1–8

Igarashi S, Bentur A, Kovler K (1999) Stresses and creep relaxation induced in restrained autogenous shrinkage of high-strength pastes and concretes. Adv Cem Res 11(4):169–177. https://doi.org/10.1680/adcr.1999.11.4.169

Neville A (2011) Properties of concrete, 5th edn. Trans-Atlantic Publications, Philadelphia, p 846

Byard BE, Schindler AK, Barnes RW (2012) Early-age cracking tendency and ultimate degree of hydration of internally cured concrete. J Mater Civ Eng 24(8):1025–1033. https://doi.org/10.1061/(asce)mt.1943-5533.0000469

Weber S, Reinhardt HW (1997) New generation of high-performance concrete: concrete with autogenous curing. Adv Cem Based Mater 6(2):59–68. https://doi.org/10.1016/s1065-7355(97)00009-6

Lyu Z et al (2020) Life-cycle crack resistance and micro characteristics of internally cured concrete with superabsorbent polymers. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119794

Trtik P, Münch B, Weiss WJ, Kaestner A, Jerjen I, Josic L, Lura PJNI (2011) Release of internal curing water from lightweight aggregates in cement paste investigated by neutron and X-ray tomography. Nucl Instrum Methods Phys Res Sect A: Accel Spectrom Detec Assoc Equip 651(1):244–249. https://doi.org/10.1016/j.nima.2011.02.012

Ma X, Liu J, Shi C (2019) A review on the use of LWA as an internal curing agent of high-performance cement-based materials. Constr Build Mater 218:385–393

Bentz DP, Weiss WJ (2011) Internal curing: a 2010 state-of-the-art review (pp 1–82). Gaithersburg: US Department of Commerce, National Institute of Standards and Technology. https://doi.org/10.6028/nist.ir.7765.

Alberty RA, Daniels F (1980) Physical chemistry: SI version.-solutions Manual.-325 S. Wiley

Abdellatief M, Alanazi H, Radwan MK, Tahwia AM (2022) Multiscale characterization at early ages of ultra-high performance geopolymer concrete. Polymers 14(24):5504. https://doi.org/10.3390/polym14245504

Niranjan Reddy BL, Vinod Kumar M (2020) Comparative review on mechanical properties of concrete with replacing curing water by self-curing compounds. IOP Conf Ser: Mater Sci Eng. https://doi.org/10.1088/1757-899x/925/1/012008

Abdellatief M, AL-Tam SM, Elemam WE, Alanazi H, Elgendy GM, Tahwia AM (2023) Development of ultra-high-performance concrete with low environmental impact integrated with metakaolin and industrial wastes. Case Stud Constr Mater 18:e01724. https://doi.org/10.1016/j.cscm.2022.e01724

Lopez M, Kahn LF, Kurtis KE (2010) High-strength self-curing low-shrinkage concrete for pavement applications. Int J Pavement Eng 11(5):333–342. https://doi.org/10.1080/10298436.2010.488731

Powers TC (1948) A discussion of cement hydration in relation to the curing of concrete. Chicago, [Portland Cement Association]

Yang J et al (2019) Research on drying shrinkage deformation and cracking risk of pavement concrete internally cured by SAPs. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.116705

Paul A et al (2021) The role of moisture transport mechanisms on the performance of lightweight aggregates in internal curing. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.121191

Abdellatief M, Elemam WE, Alanazi H, Tahwia AM (2023) Production and optimization of sustainable cement brick incorporating clay brick wastes using response surface method. Ceram Int 49(6):9395–9411. https://doi.org/10.1016/j.ceramint.2022.11.144

Wash R (2002) Water security. Water Well J 56:58

Mekonnen MM, Hoekstra AY (2016) Four billion people facing severe water scarcity. Sci Adv 2(2):e1500323. https://doi.org/10.1126/sciadv.1500323

El-Dieb AS (2007) Self-curing concrete: water retention, hydration and moisture transport. Constr Build Mater 21(6):1282–1287. https://doi.org/10.1016/j.conbuildmat.2006.02.007

Lokeshwari M, Bandakli BP, Tarun SR, Sachin P, Kumar V (2021) A review on self-curing concrete. Mater Today: Proc 43:2259–2264. https://doi.org/10.1016/j.matpr.2020.12.859

Bentz DP, Snyder KA (1999) Protected paste volume in concrete: extension to internal curing using saturated lightweight fine aggregate. Cem Concr Res 29(11):1863–1867. https://doi.org/10.1016/s0008-8846(99)00178-7

Zhutovsky S, Kovler K, Bentur A (2002) Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage. Mater Struct 35:97–101. https://doi.org/10.1007/bf02482108

Jensen OM, Lura P (2006) Techniques and materials for internal water curing of concrete. Mater Struct 39(9):817–825. https://doi.org/10.1617/s11527-006-9136-6

Henkensiefken R, Castro J, Kim H, Bentz D, Weiss J (2009) Internal curing improves concrete performance throughout its life. Concrete InFocus 8(5):22–30

Golias M, Weiss J, Bentz D (2013) Influence of exposure conditions on the efficiency of internal curing in concrete. Adv Civ Eng Mater 2(1):20120023. https://doi.org/10.1520/acem20120023

Liu F et al (2017) Internal curing of high-performance concrete using cenospheres. Cem Concr Res 95:39–46. https://doi.org/10.1016/j.cemconres.2017.02.023

Kim K, Chun S (2015) Evaluation of internally cured concrete pavement using environmental responses and critical stress analysis. Int J Concr Struct Mater 9(4):463–473. https://doi.org/10.1007/s40069-015-0115-6

Wei Y, Wang Y, Gao X (2015) “Effect of internal curing on moisture gradient distribution and deformation of a concrete pavement slab containing pre-wetted lightweight fine aggregates. Dry Technol 33(3):355–364. https://doi.org/10.1080/07373937.2014.952740

Al Saffar DM, Al Saad AJK, Tayeh BA (2019) Effect of internal curing on behavior of high-performance concrete: an overview. Case Stud Constr Mater. https://doi.org/10.1016/j.cscm.2019.e00229

Chen F et al (2019) Internal curing effect and compressive strength calculation of recycled clay brick aggregate concrete. Materials. https://doi.org/10.3390/ma12111815

Chaitanya C et al (2019) Effect of LECA on mechanical properties of self-curing concrete. MaterToday: Proc 19:484–488. https://doi.org/10.1016/j.matpr.2019.07.640

Balapour M et al (2020) Potential use of lightweight aggregate (LWA) produced from bottom coal ash for internal curing of concrete systems. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2019.103428

Ali Khan R, Gupta C, Alam S (2021) Strength and durability of self-curing concrete developed using calcium lignosulfonate. J King Saud Univ—Eng Sci. https://doi.org/10.1016/j.jksues.2021.02.002

Bandara MMHW, Mampearachchi WK (2021) Mitigate the curing problems of concrete pavements by using heated non-expansive clay particles as internal curing agent. Road Mater Pavement Des 22(4):969–982. https://doi.org/10.1080/14680629.2019.1700824

Gawad MA, Fawzi NM (2021) Use of thermostone waste aggregates for internal curing of reactive powder concrete. IOP Conf Ser: Earth Environ Sci 877(1):012043. https://doi.org/10.1088/1755-1315/877/1/012043

Dhir RK et al (1994) An investigation into the feasibility of formulating “self-cure” concrete. Mater Struct 27(10):606–615. https://doi.org/10.1007/bf02473130

Justs J et al (2015) Internal curing by superabsorbent polymers in ultra-high-performance concrete. Cem Concr Res 76:82–90. https://doi.org/10.1016/j.cemconres.2015.05.005

Bashandy AA (2016) Self-curing concrete under sulfate attack. Arch Civ Eng 62(2):3–18. https://doi.org/10.1515/ace-2015-0061

Song C, Choi YC, Choi S (2016) Effect of internal curing by superabsorbent polymers—internal relative humidity and autogenous shrinkage of alkali-activated slag mortars. Constr Build Mater 123:198–206. https://doi.org/10.1016/j.conbuildmat.2016.07.007

Almeida FCR, Klemm AJ (2018) Efficiency of internal curing by superabsorbent polymers (SAP) in PC-GGBS mortars. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2018.01.002

Lyu Z et al (2019) Research on shrinkage development and fracture properties of internal curing pavement concrete based on humidity compensation. Constr Build Mater 203:417–431. https://doi.org/10.1016/j.conbuildmat.2019.01.115

Guo L et al (2021) Texture analysis of the microstructure of concrete with different concentrations of superabsorbent polymer after internal curing. Mater Today Commun 27:102361. https://doi.org/10.1016/j.mtcomm.2021.102361

Qin X et al (2020) Research on water transport behaviors and hydration characteristics of internal curing pavement concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.118714

Rizzuto JP et al (2020) Effect of self-curing admixture on concrete properties in hot climate conditions. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.119933

Shen D et al (2020) Influence of super absorbent polymers on early-age behavior and tensile creep of internal curing high strength concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.120068

Singh K (2021) Mechanical properties of self-curing concrete studied using polyethylene glycol-400: a-review. Mater Today: Proc 37:2864–2871. https://doi.org/10.1016/j.matpr.2020.08.662

Vijayan DS et al (2020) An experimental study on mechanical and durable properties of self-curing concrete by adding admixture. Mater Today: Proc 33:496–501. https://doi.org/10.1016/j.matpr.2020.05.071.10.1016/j.matpr.2020.05.071

Kastro Kiran V et al (2021) A novel approach on properties of internal curing concrete and impact of salts. IOP Conf Ser: Mater Sci Eng 1057:012078. https://doi.org/10.1088/1757-899x/1057/1/012078

Rodríguez-Álvaro R et al (2021) “Waste-based porous materials as water reservoirs for the internal curing of concrete: a review. Constr Build Mater 299:124244. https://doi.org/10.1016/j.conbuildmat.2021.124244

Shen A et al (2018) Relationship between flexural strength and pore structure of pavement concrete under fatigue loads and Freeze-thaw interaction in seasonal frozen regions. Constr Build Mater 174:684–692. https://doi.org/10.1016/j.conbuildmat.2018.04.165

Chidiac SE et al (2021) Efficiency measure of SAP as internal curing for cement using NMR & MRI. Constr Build Mater 278:122365. https://doi.org/10.1016/j.conbuildmat.2021.122365

Shravan Kumar A, Gopi R, Murali K (2021) Comparative studies on conventional concrete and self-curing concrete. Mater Today: Proc 46:8790–8794. https://doi.org/10.1016/j.matpr.2021.04.149

Yang L et al (2021) Factors affecting the effectiveness of internal curing: a review. Constr Build Mater 267:121017. https://doi.org/10.1016/j.conbuildmat.2020.121017

Zhang S et al (2021) A method for internal curing water calculation of concrete with super absorbent polymer. Adv Civ Eng 2021:1–14. https://doi.org/10.1155/2021/6645976

Zheng X et al (2021) Frost resistance of internal curing concrete with calcined natural zeolite particles. Constr Build Mater 288:123062. https://doi.org/10.1016/j.conbuildmat.2021.123062

Mihaljevic SN, Chidiac SE (2022) Effective free water diffusion coefficient of cement pastes internally cured with superabsorbent polymers. J Build Eng 45:103600. https://doi.org/10.1016/j.jobe.2021.103600

Malathy R, Chung IM, Prabakaran M (2020) Characteristics of fly ash-based concrete prepared with bio admixtures as internal curing agents. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.120596

Memon RP et al (2020) ‘Introducing effective microorganism as self-curing agent in self-cured concrete. IOP Conf Ser: Mater Sci Eng. https://doi.org/10.1088/1757-899x/849/1/012081

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Each of the authors confirms that this manuscript has not been previously published and is not currently considered by any other journal. Additionally, the authors have approved the contents of this paper and have agreed to the Journal of Innovative Infrastructure Solutions submission policies. Each named author has substantially contributed to conducting the underlying review and drafting this manuscript. Additionally, to the best of our knowledge, the named authors have no conflict of interest, financial, or otherwise.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Ethical approval

Human subjects are not involved in the study and hence it is not applicable.

Informed consent

For this type of study, formal consent is not required.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Panwar, S., Jindal, A. A review on self-curing agents. Innov. Infrastruct. Solut. 8, 282 (2023). https://doi.org/10.1007/s41062-023-01237-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-023-01237-z