Abstract

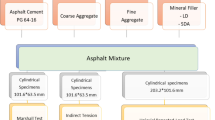

Cement manufacturing is a major responsible source for environmental degradation, contributing around 8% of greenhouse gas emissions. This research aims to promote consciousness of the importance of supplementary cementitious materials (SCMs) in the construction industry for long-term sustainability. Multiple binary mixes were developed in this study by replacing slag-based mineral admixtures such as cinder and processed ground granulated blast furnace slag (GGBS) with ordinary portland cement (OPC) as an additional cementitious material (SCM). The reactivity of cinder and processed GGBS with cement yielded encouraging findings, motivating the authors to investigate the behavior of these materials in concrete. The experiment aimed to determine the influence of cinder and processed GGBS on the fresh and hardened characteristics of binary blended concrete. Moreover, cinder and processed GGBS provided positive outcomes in concrete. However, the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) and analytical hierarchy process (AHP) methodologies are used for optimization in the current study. Compared to the control mix, AHP and TOPSIS demonstrate that effective cinder utilization is 30% and 20% of processed GGBS, respectively, increasing split tensile strength by 16–20%, flexural strength by 28–30%, and shear strength by 35–38%. The thermogravimetric analysis demonstrates a substantial weight loss while using cinder at a higher temperature than processed GGBS or control mix. In addition, this research also presents the impact assessment, which emphasizes the benefits of slag against OPC. Furthermore, from an economic point of view, the performed cost analysis indicates savings of 10–13% for optimal dosages of respective replacements.

Similar content being viewed by others

References

Keeble BR (1988) Report of the world commission on environment and development: Our Common Future

Jiang Y, Ling T-C, Shi C, Pan S-Y (2018) Characteristics of steel slag and their use in cement and concrete - a review. Resour Conserv Recycl 136:187–197

Flower DJM, Sanjayan JG (2007) Green house gas emissions due to concrete manufacture. Int J Life Cycle Assess 12:282–288. https://doi.org/10.1007/s11367-007-0327-3

Sharma AK, Sivapullaiah PV (2016) Ground granulated blast furnace slag amended fly ash as an expansive soil stabilizer. Soils Found 56:205–212. https://doi.org/10.1016/j.sandf.2016.02.004

Babu UR, Ramana NV, Babu SV, Pavithra P (2020) Effect of pond ash on black stone waste aggregate concrete. Emerging trends in civil engineering. Springer, Singapore, pp 345–353

Nicolae M, Vîlciu I, Zǎman F (2007) X-ray diffraction analysis of steel slag and blast furnace slag viewing their use for road construction. UPB Sci Bull Ser B Chem Mater Sci 69:99–108

Yildirim IZ, Prezzi M (2011) Chemical, mineralogical, and morphological properties of steel slag. Adv Civ Eng. https://doi.org/10.1155/2011/463638

Tsakiridis PE, Papadimitriou GD, Tsivilis S, Koroneos C (2008) Utilization of steel slag for Portland cement clinker production. J Hazard Mater 152:805–811. https://doi.org/10.1016/j.jhazmat.2007.07.093

Yi H, Xu G, Cheng H, et al (2012) An Overview of Utilization of Steel Slag. In: Procedia environmental sciences. pp 791–801

Rashad AM (2018) An overview on rheology, mechanical properties and durability of high-volume slag used as a cement replacement in paste, mortar and concrete. Constr Build Mater 187:89–117. https://doi.org/10.1016/j.conbuildmat.2018.07.150

Yu C, Sun W, Scrivener K (2015) Degradation mechanism of slag blended mortars immersed in sodium sulfate solution. Cem Concr Res 72:37–47. https://doi.org/10.1016/j.cemconres.2015.02.015

De Belie N, Soutsos M, Gruyaert E (2018) Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials: State-of-the-Art Report of the RILEM Technical Committee 238-SCM, Working Group 4

Rashad AM (2018) An overview on rheology, mechanical properties and durability of high volume slag used as cement replacement in paste, mortar and concrete. Constr Build Mater 187:89–117

Pfingsten J, Rickert J, Lipus K (2018) Estimation of the content of ground granulated blast furnace slag and different pozzolanas in hardened concrete. Constr Build Mater 165:931–938. https://doi.org/10.1016/j.conbuildmat.2018.01.065

Gencel O, Karadag O, Oren OH, Bilir T (2021) Steel slag and its applications in cement and concrete technology: a review. Constr Build Mater 283:122783. https://doi.org/10.1016/j.conbuildmat.2021.122783

Martins ACP, Franco de Carvalho JM, Costa LCB et al (2021) Steel slags in cement-based composites: An ultimate review on characterization, applications and performance. Constr Build Mater 291:123265. https://doi.org/10.1016/j.conbuildmat.2021.123265

Salla SR, Modhera CD, Babu UR (2021) An experimental study on various industrial wastes in concrete for sustainable construction. J Adv Concrete Technol 19:133–148. https://doi.org/10.3151/jact.19.133

Standard B of I (2016) IS 383-2016 Coarse and fine aggregate for concrete — specification

Salla SR, Babu UR, Kannuzia AK et al (2022) The analytical framework by AHP and TOPSIS for the incorporation of manufactured sand in concrete : Fresh and Hardened properties. Neuroquantology 20:7102–7116. https://doi.org/10.14704/nq.2022.20.8.NQ44734

Bureau of Indian Standard (2018) IS 9103 - 1999 concrete admixtures - specification

Bureau of Indian Standard (2019) IS 10262 - 2019 concrete mix proportioning - guidelines

Bureau of Indian Standard (2018) IS 1199 - 1959 Methods of sampling and analysis of concrete

ASTM C1585–13 (2013) Standard test method for measurement of rate of absorption of water by hydraulic cement concretes. ASTM Int 41:1–6. https://doi.org/10.1520/C1585-20.2

Standard B of I (2018) IS 516 (Part 2/Sec 1)-2018 Hardened Concrete — Methods of Test

Standard B of I (2018) IS 516-1959 Methods of tests for strength of concrete

Standard B of I (2013) IS 5816-1999 Splitting tensile strength of concrete - Method of test

N.K. B, Modhera C.D (2001) Shear Strength reinforced concrete. ICI J 47–52

Dossche C, Boel V, De Corte W (2017) Use of life cycle assessments in the construction sector: critical review. Proc Eng 171:302–311. https://doi.org/10.1016/j.proeng.2017.01.338

Rama Jyosyula SK, Surana S, Raju S (2020) Role of lightweight materials of construction on carbon dioxide emission of a reinforced concrete building. Mater Today Proc 27:984–990. https://doi.org/10.1016/j.matpr.2020.01.294

Manjunatha M, Preethi S, Mounika HG, Niveditha KN et al (2021) Life cycle assessment (LCA) of concrete prepared with sustainable cement-based materials. Mater Today Proc 47:3637–3644. https://doi.org/10.1016/j.matpr.2021.01.248

Lemay L (2011) Life cycle assessment of concrete buildings, Dissertation, University of California

Lvel J, Watson R, Abbassi B, Abu-Hamatteh ZS (2020) Life cycle analysis of concrete and asphalt used in road pavements. Environ Eng Res 25:52–61. https://doi.org/10.4491/eer.2018.399

Hammond GP, Jones CI (2008) Embodied energy and carbon in construction materials. Proc Inst Civ Eng Energy 161:87–98. https://doi.org/10.1680/ener.2008.161.2.87

Asadollahfardi G, Katebi A, Taherian P, Panahandeh A (2021) Environmental life cycle assessment of concrete with different mixed designs. Int J Constr Manag 21:665–676. https://doi.org/10.1080/15623599.2019.1579015

Fan D, Yu R, Shui Z et al (2021) A new development of eco-friendly Ultra-High performance concrete (UHPC): towards efficient steel slag application and multi-objective optimization. Constr Build Mater 306:124913. https://doi.org/10.1016/j.conbuildmat.2021.124913

Rashid K, Hameed R, Ahmad HA et al (2018) Analytical framework for value added utilization of glass in concrete: mechanical and environmental performance. Waste Manag. https://doi.org/10.1016/j.wasman.2018.07.052

Venkata Rao R (2007) Decision making in the manufacturing environment: using graph theory and fuzzy multiple attribute decision making methods. Springer Science and Business Media, Berlin

Kupwade-Patil K, Al-Aibani AF, Abdulsalam MF et al (2016) Microstructure of cement paste with natural pozzolanic volcanic ash and Portland cement at different stages of curing. Constr Build Mater 113:423–441. https://doi.org/10.1016/j.conbuildmat.2016.03.084

Kosmatka SH, Wilson ML (2011) Design and control of concrete mixtures – the guide to applications, Methods and Materials, EB001, 15th edn. Portland Cement Association, Skokie, Illinois, USA

Mamlouk MS, Zaniewski JP (2011) Materials for Civil and Construction Engineers, 3rd edn. Pearson Education, Inc., Upper Saddle River, New Jersey

Pansu M, Gautheyrou J (2006) Handbook of Soil Analysis - Mineralogical, Organic and Inorganic Methods. Springer-Verlag, Berlin, Heidelberg

Horgnies M, Chen JJ, Bouillon C (2013) Overview about the use of fourier transform infrared spectroscopy to study cementitious materials. WIT Trans Eng Sci 77:251–262. https://doi.org/10.2495/MC130221

Hôpital EL, Lothenbach B, Kulik DA, Scrivener K (2016) Cement and concrete research influence of calcium to silica ratio on aluminium uptake in calcium silicate hydrate. Cem Concr Res 85:111–121. https://doi.org/10.1016/j.cemconres.2016.01.014

Alarcon-ruiz L, Platret G, Massieu E, Ehrlacher A (2005) The use of thermal analysis in assessing the effect of temperature on a cement paste. Cement Concrete Res 35:609–613. https://doi.org/10.1016/j.cemconres.2004.06.015

Gallucci E, Zhang X, Scrivener KL (2013) Cement and Concrete Research Effect of temperature on the microstructure of calcium silicate hydrate ( C-S-H ). Cem Concr Res 53:185–195. https://doi.org/10.1016/j.cemconres.2013.06.008

Phung QT, Maes N, Seetharam S (2019) Pitfalls in the use and interpretation of TGA and MIP techniques for Ca-leached cementitious materials. Mater Des 182:108041. https://doi.org/10.1016/j.matdes.2019.108041

El-Jazairi B, Illston JM (1977) A simultaneous semi-isothermal method of thermogravimetry and derivative thermogravimetry, and its application to cement pastes. Cem Concr Res 7:247–257. https://doi.org/10.1016/0008-8846(77)90086-2

Kim T, Olek J (2012) Effects of sample preparation and interpretation of thermogravimetric curves on calcium hydroxide in hydrated pastes and mortars. Transp Res Rec. https://doi.org/10.3141/2290-02

Patel S, Orlov A, Ariyachandra E, Peethamparan S (2021) Effect of flue gas temperature on NO 2 adsorption by aged recycled concrete Waste : DRIFTS, TGA and BET study. Chem Eng J 420:130413. https://doi.org/10.1016/j.cej.2021.130413

De Weerdt K, Ben HM, Le Saout G et al (2011) Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem Concr Res 41:279–291. https://doi.org/10.1016/j.cemconres.2010.11.014

Rosado LP, Vitale P, Penteado CSG, Arena U (2017) Life cycle assessment of natural and mixed recycled aggregate production in Brazil. J Clean Prod 151:634–642. https://doi.org/10.1016/j.jclepro.2017.03.068

Martinez-Arguelles G, Acosta MP, Dugarte M, Fuentes L (2019) Life cycle assessment of natural and recycled concrete aggregate production for road pavements applications in the northern region of colombia: case study. Transp Res Rec 2673:397–406. https://doi.org/10.1177/0361198119839955

Gursel P (2014) Life-cycle assessment of concrete: decision-support tool and case study application. UC Berkeley 513

Acknowledgements

The authors are thankful to Civil Tech. Laboratory – Surat, JEMS Multi Testing Laboratory – Surat, Chandrika Traders – Surat, and Suyog Element India Pvt. Ltd. for their cooperation. The authors acknowledge the Material Research Centre (MRC) – Malaviya National Institute of Technology – Jaipur for TG analysis and S V National Institute of Technology – Surat for XRD and FTIR analysis. The authors would also like to thank the anonymous reviewers who contributed constructive advice to the prominent theme of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests that could have appeared to influence the work reported in this paper. Also, the authors declare that there is no conflict of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Salla, S.R., Uppara, R.B., Kannazia, A.K. et al. An experimental and environmental impact assessment of slag-based mineral admixture for sustainable development. Innov. Infrastruct. Solut. 8, 29 (2023). https://doi.org/10.1007/s41062-022-00998-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00998-3