Abstract

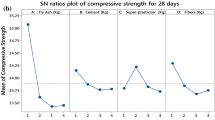

The tremendous growth in the construction industry has led to a shortage of natural water and aggregates for concrete. It is an acute problem faced by the construction industry in recent years. To overcome this problem, attention is focused on finding alternatives to provide an amicable solution to this problem. Using industrial waste as coarse aggregate and treated wastewater for mixing is a great opportunity. In the present research, the microbiologically induced calcium carbonate precipitation technique is adopted by using steel slag as coarse aggregate, different types of wastewaters for mixing, and isolated bacteria to develop bio-concrete with maximum strength and durability. Optimum conditions of the parameters are determined using the Taguchi approach L9 (33) orthogonal array layout. Analysis of means indicates that optimum conditions for maximum compressive strength and durability of bio-concrete are reported as 50% steel slag aggregate replacement with natural aggregate, 75 ml bacterial solution with treated wastewater through construction wetland. Analysis of variance indicates that steel slag aggregate has made the greatest impact on the compressive strength and durability of bio-concrete followed by mixing water and bacterial solution. Furthermore, SEM and XRD results show the compact microstructure of concrete due to the microbiological precipitation of calcium carbonate by bacteria.

Similar content being viewed by others

Data availability

All data and materials support the published claims and comply with field standards.

Code availability

Not applicable.

References

Aggregate Business International (2013) Booming Indian aggregates market. Available at: http://www.aggbusiness.com/sections/market-reports/features/booming-indian-aggregatesmarket/

Palankar N, Shankar AR, Mithun BM (2016) Durability studies on eco-friendly concrete mixes incorporating steel slag as coarse aggregates. J Clean Prod 129:437–448

Anastasiou E, Filikas KG, Stefanidou M (2014) Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr Build Mater 50:154–161

Sezer Gİ, Gülderen M (2015) Usage of steel slag in concrete as fine and/or coarse aggregate. Indian J Eng Mater Sci 22:339–344

Papayianni I, Anastasiou E (2010) Production of high-strength concrete using high volume of industrial by-products. Constr Build Mater 24:1412–1417

Maslehuddin M, Sharif AM, Shameem M, Ibrahim M, Barry MS (2003) Comparison of properties of steel slag and crushed limestone aggregates concrete. Constr Build Mater 17(2):105–112

Abu-Eishah SI, El-Dieb AS, Bedir MS (2012) Performance of concrete mixtures made with electric erc furnace (EAF) steel slag aggregate produced in the Arabian Gulf region. Constr Build Mater 34:249–256

Noruzman AH, Muhammad B, Ismail M, Abdul-Majid Z (2012) Characteristics of treated effluents and their potential applications for producing concrete. J Environ Manag 110:27–32

Achal V (2010) Microbial remediation of defects in building materials and structures. PhD Thesis, Thapar University, Patiala, India

Achal V, Mukherjee A, Basu PC, Reddy MS (2009) Lactose mother liquor as an alternative nutrient source for microbial concrete production by Sporosarcina Pasteurii. J Ind Microbiol Biotechnol 36(3):433–438

Sarkar M, Alam N, Chaudhuri B, Chattopadhyay B, Mandal S (2015) Development of an improved E. Coli bacterial strain for green and sustainable concrete technology. RSC Adv 5:32175–32182

Tanyildizi H, Şahin M (2015) Application of Taguchi method for optimization of concrete strengthened with polymer after high temperature. Constr Build Mater 79:97–103

Türkmen İ, Gül R, Çelik C, Demirboğa R (2003) Determination by the Taguchi method of optimum conditions for mechanical properties of high strength concrete with admixtures of silica fume and blast furnace slag. Civ Eng Environ Syst 20(2):105–118

BIS 269 (2015) Ordinary Portland Cement—specification. Bureau of Indian Standards, New Delhi, India

BIS 2386 (1963) Methods of test for aggregates for concrete, (Part I–IV). Bureau of Indian Standards, New Delhi, India

Kumar AP, Akila D (2015) An experimental work on concrete by adding Bacillus subtilis. Int J Emerg Technol Eng 2:69–73

ParvezAlam A, Anwar K, Ansari M (2016) Bacterial concrete-A remedy for micro cracks. Thesis, Anjuman-I-Islam’s Kalsekar Technical Campus, Navi Mumbai, India

Ravindranatha KN, Likhit ML (2014) Self-healing material bacterial concrete. Int J Res Eng Technol 3:656–659

BIS 10262 (2009) Concrete mix proportioning-guidelines. Bureau of Indian Standards, New Delhi, India

BIS 456 (2000) Plain and reinforced concrete-code of practice. Bureau of Indian Standards, New Delhi, India

BIS 516 (1959) Methods of tests for strength of concrete. Bureau of Indian Standards, New Delhi, India

ASTM C1202 (2012) Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration. American Society for Testing and Materials, Philadelphia

ASTM C1723 (2010) Standard guide for examination of hardened concrete using scanning electron microscopy. American Society for Testing and Materials, Philadelphia.

Cimbala JM (2014) Taguchi orthogonal arrays. Pennsylvania State University, pp 1–3

Mauthoor S, Mohee R, Kowlesser P (2016) Characterisation of electric arc furnace slags as concrete aggregate in a small island developing state: a preliminary study. Constr Build Mater 105:459–464

Li M, Zhu X, Mukherjee A, Huang M, Achal V (2017) Biomineralization in metakaolin modified cement mortar to improve its strength with lowered cement content. J Hazard Mater 329:178–184

Khaliq W, Ehsan MB (2016) Crack healing in concrete using various bio influenced self-healing techniques. Constr Build Mater 102:349–357

Wong LS (2015) Microbial cementation of ureolytic bacteria from the genus Bacillus: a review of the bacterial application on cement-based materials for cleaner production. J Clean Prod 93:5–17

Al-ghusain I, Terro MJ (2003) Use of treated wastewater for concrete mixing in Kuwait. Kuwait J Sci Eng 30(1):213–228

Siddique R, Chahal NK (2011) Effect of ureolytic bacteria on concrete properties. Constr Build Mater 25:3791–3801

Pacheco-Torgal F, Labrincha JA (2013) Biotech cementitious materials: some aspects of an innovative approach for concrete with enhanced durability. Constr Build Mater 40:1136–1141

Chahal N, Siddique R, Rajor A (2012) Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr Build Mater 28:351–356

Nosouhian F, Mostofinejad D, Hasheminejad H (2015) Influence of biodeposition treatment on concrete durability in a sulphate environment. Biosys Eng 133:141–152

Gambhir ML (2013) Concrete technology: theory and practice. Tata McGraw-Hill Education

Neville AM (2012) Properties of concrete, 5th edn. Pearson Education Limited, England

Balam NH, Mostofinejad D, Eftekhar M (2017) Use of carbonate precipitating bacteria to reduce water absorption of aggregates. Constr Build Mater 141:565–577

Chaulia PK, Das R (2008) Process parameter optimization for fly ash brick by Taguchi method. Mater Res 11:159–164

Das D, Chatterjee A (2013) Taguchi and ANOVA approach for optimization of flow characteristics of self-compacting concrete. Emerg Mater Res 3:37–45

Lafifi B, Rouaiguia A, Boumazza N (2019) Optimization of geotechnical parameters using Taguchi’s design of experiment (DOE), RSM and desirability function. Innov Infrastruct Solut 4:1–12

Yan S, Sagoe-crentsil K, Shapiro G (2012) Properties of cement mortar incorporating de-inking wastewater from waste paper recycling. Constr Build Mater 29:51–55

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Saxena, S., Tembhurkar, A.R. Optimization of process parameters by Taguchi method for maximizing strength and durability of bio concrete. Innov. Infrastruct. Solut. 7, 258 (2022). https://doi.org/10.1007/s41062-022-00850-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-022-00850-8