Abstract

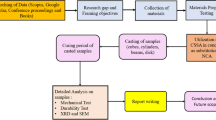

The aim of this research is to investigate the engineering properties and geochemical analysis of sandstone that is available in the Injana Formation to show its tentative quality assessment of the possibility of using sandstone as a construction material. Two sections of the laboratory experiment were discussed. The first part has discussed the physical and mechanical properties of sandstone aggregate which includes: porosity, moisture content, water absorption, dry density, uniaxial compressive strength, Schmidt Hammer Rebound, Los Angeles abrasion, weathering behavior and chemical composition. The second part has discussed the effect of sandstone powders as partial replacement of cement on the compressive strength of mortar. According to results obtained, the average values of Los Angeles abrasion values (33.36%), uniaxial compressive strength (57.43 MPa), and Schmidt's hardness (30) indicated that sandstone aggregate was strong and durable, making it suitable for use in concrete and road construction. On the other hand, the compressive strength of mortar-containing sandstone powders (SSP) up to 20% instead of cement there was no significant reduction in the compressive strength. So, it has been found that sandstone contributes to the decrease of cement consumption and can be considered a local economical material for non-structural concrete applications. The results indicate that there is a strong correlation relationship between the physical and strength properties of sandstone using regression models with statistical equations; it was found out that the sandstone aggregate has good engineering properties.

Similar content being viewed by others

References

Dixit MK, Fernández-Solís JL, Lavy S, Culp CH (2012) Need for an embodied energy measurement protocol for buildings: a review paper. Renew Sustain Energy Rev 16(6):3730–3743. https://doi.org/10.1016/j.rser.2012.03.021

Eljufout T, Alhomaidat F (2021) Evaluation of natural building stones’ characterizations using ultrasonic testing technique. Arab J Sci Eng. https://doi.org/10.1007/s13369-021-05825-y

Juenger M, Provis JL, Elsen J, Matthes W, Hooton RD, Duchesne J, Belie ND (2012) Supplementary cementitious materials for concrete: characterization needs. MRS Proc. https://doi.org/10.1557/opl.2012.1536

Nicoara AI, Stoica AE, Vrabec M, Šmuc Rogan N, Sturm S, Ow-Yang C, Vasile BS (2020) End-of-life materials used as supplementary cementitious materials in the concrete industry. Materials 13(8):1954. https://doi.org/10.3390/ma13081954

Ghobadi MH, Babazadeh R, Khodabakhsh S (2014) Petrophysical and durability tests on sandstones for the evaluation of their quality as building stones using analytical hierarchy process (AHP). Geopersia 4(1):25–43

Zorlu K, Gokceoglu C, Ocakoglu F, Nefeslioglu HA, Acikalin S (2008) Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng Geol 96(3–4):141–158. https://doi.org/10.1016/j.enggeo.2007.10.009

Cultrone G, Luque A, Sebastián E (2012) Petrophysical and durability tests on sedimentary stones to evaluate their quality as building materials. Q J Eng GeolHydrogeol 45(4):415–422. https://doi.org/10.1144/qjegh2012-007

Petrounias P, Giannakopoulou PP, Rogkala A, Kalpogiannaki M, Koutsovitis P, Damoulianou M-E, Koukouzas N (2020) Petrographic characteristics of sandstones as a basis to evaluate their suitability in construction and energy storage applications. A case study from klepa Nafpaktias (Central Western Greece). Energies 13(5):1119. https://doi.org/10.3390/en13051119

Kumar S, Gupta RC, Shrivastava S (2016) Strength, abrasion and permeability studies on cement concrete containing quartz sandstone coarse aggregates. Constr Build Mater 125:884–891. https://doi.org/10.1016/j.conbuildmat.2016.08.106

Ruedrich J, Bartelsen T, Dohrmann R, Siegesmund S (2010) Building sandstone integrity affected by the process of hygric expansion. Environ Earth Sci, p 10

Al-Juboury AIA (2009) The upper Miocene Injana (Upper Fars) formation of Iraq: insights on provenance history. Arab J Geosci 2(4):337–364. https://doi.org/10.1007/s12517-009-0045-1

Tamar-Agha MY, Salman NA (2015) Facies and depositional environments of Injana formation in Zawita, Amadia and Zakho Areas, Northern Iraq. Iraqi Bull Geol Mining 11(3):39–59

Petrography and Provenance of the Sandstone of Injana and Mukdadiya Formations (Upper Miocene/Pliocene) at Duhok Governorate, Northern Iraq (2018). Iraqi J Sci, vol 59, no 4. https://doi.org/10.24996/ijs.2018.59.4b.10

Rathore K, Agrwal V, Nagar R (2020) Green concrete: using quarry waste of sandstone as fine aggregate with high levels of microfines. Mater Today Proc 32:728–733. https://doi.org/10.1016/j.matpr.2020.03.463

He Z, Hu L, Li Y, Hu J, Shao Y (2018) Use of sandstone powder as a mineral additive for concrete. Constr Build Mater 186:276–286. https://doi.org/10.1016/j.conbuildmat.2018.06.228

Sissakian VK, Mahdi AI, Amin RM, Salman BM (1997) The Nfayil formation: a new middle miocene lithostratigraphic unit in west Iraq. Iraqi Geol J 30(1):61–65

Jassim HM, Saad SA, Ghafour BD (2013) Slope stability assessment along the Haibat Sultan main road, Koya, Kurdistan. In: First international symposium on urban development: Koya as a Case Study. https://doi.org/10.2495/isud130051

Al Naqib KM (1960) Geology of the southern area of Kirkuk Liwa, Iraq: 2d Arab Petroleum Congress Proceeding, Cairo, pp 1–50

Jassim SZ, Karim SA, Basi MA, Al-Mubarak MA, Munir J (1984) Final report on the regional geological survey of Iraq, vol. 3, Stratigraphy. GEOSURV, Int Rep No. 1147, p 498

Bolton CMG (1954) Geological map of kurdistan series, scale 1: 100 000, sheet K6, Halabcha. GEOSURV, Int. Rep. No. 278

New Zea Land Geotechnical Society (NZGS) (2005) Field description of soil and rock. Publication of NZ Geotechnical Society, New Zealand

ASTM C131 (2008) Standard test method for resistance to degradation of small-size coarse aggregate by abrasion and impact in the Los Angeles MAchine; ASTM: West Conshohocken, PA, USA

ASTM C566–13 (2013). Standard test method for total evaporable moisture content of aggregate by drying. ASTM Standards

ASTM A (2015) Standard test method for relative density (specific gravity) and absorption of coarse aggregate. ASTM C 128

ASTM C 29/C 29M—Standard Test Method for Bulk Density ("Unit Weight") and Voids in Aggregate

ASTM D5731–08 (2013) Standard test method for determination of the point load strength index of rock and application to rock strength classifications

Isrm BE (1981) Suggested methods: rock characterization, testing and monitoring. In: ISRM commission on testing methods. Pergamon, Oxford

Iraqi Standard Specification (IQS), ‘No.5/1984, Portland Cement’, Central Organization for Standardization & Quality Control (COSQC), Baghdad, Iraq

Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. https://doi.org/10.1520/c0305-99

Specification for Flow Table for Use in Tests of Hydraulic Cement. https://doi.org/10.1520/c0230_c0230m-13

Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). https://doi.org/10.1520/c0109_c0109m-12

Dragovich D, Egan M (2011) Salt weathering and experimental desalination treatment of building sandstone, Sydney (Australia). Environ Earth Sci 62:277–288

Siegesmund S, Snethlage R (2011) Stone in architecture, 4th edn. Springer, Berlin. https://doi.org/10.1007/978-3-642-14475-2

Pinho A, Rodrigues JA, Gomes C, Duarte IM (2006) Overview of the evaluation of the state of rock weathering by visual inspection. Geological Society of London, IAEG2006 Paper number 260, pp 1–7

Palchick V, Hatzor YH (2004) The influence of porosity on tensile and compressive strength of porous chalks. Rock Mech Rock Eng 37(4):331–341

Tuǧrul A (2004) The effect of weathering on pore geometry and compressive strength of selected rock types from Turkey. Eng Geol 75(3–4):215–227. https://doi.org/10.1016/j.enggeo.2004.05.008

Tuğrul A, Zarif İH (2002) Aggregate production in İstanbul, Turkey. In: Proceedings of international symposium on industrial minerals and building stones. Vol 15, p 18

Mosch S, Siegesmund S (2007) Statistische bewertung gesteintechnischer Kenndaten von Natursteinen. Z dtsch Ges Geowiss 158(4):821–868

Mosch S (2009) Optimierung der exploration, gewinnung und materialcharakterisierung von naturwerksteinen. Diss Univ Göttingen, Göttingen.

ASTM- C97 (1977) Test for specific gravity of natural building stone

Mirwald P (1997) Physikalische Eigenschaften der Gesteine. In: Berufsbildungswerk des Steinmetz- und Bildhauerhandwerks e.V. (ed) Ebner, Ulm

Khudhur ME (2021) The suitability of Tigris river sediments from Tikrit, Northern Iraq, for concrete production and road construction purposes. Iraqi J Sci. https://doi.org/10.24996/ijs.2021.62.4.14

Widiarti N, Lailun Ni’mah Y, Bahruji H, Prasetyoko D (2019) Development of CaO from natural calcite as a heterogeneous base catalyst in the formation of biodiesel: review. J Renew Mater 7(10):915–939. https://doi.org/10.32604/jrm.2019.07183

Hewlett PC (2004) Lea’s Chemistry of Cement and Concrete, 4th edn. Elsevier, Hoboken, p 1066

Bhatty JI, Miller FM, Kosmatka SH, Bohan RB (2011) Innovations in Portland Cement Industry, 2nd edn. Portland Cement Association (PCA), Illinois, p 1734

ASTM C 618 (1991) Standard specification for fly ash and raw or calcined natural pozzolan for use as a mineral admixture in Portland cement concrete, annual book of ASTM Standards, Philadelphia, USA

Farny JA, Kosmatka SH (1997) Diagnosis and control of alkali-aggregate reactions in concrete. Portland Cement Association, Skokie, pp 1–15

Liska M, Lea FM, Hewlett PC (2019) Lea’s chemistry of cement and concrete. Butterworth-Heinemann

Saidi T, Hasan M (2020) The effect of partial replacement of cement with diatomaceous earth (DE) on the compressive strength and absorption of mortar. J King Saud Univ Eng Sci. https://doi.org/10.1016/j.jksues.2020.10.003

Acknowledgements

The author would like to express the deepest appreciation of the University of Koya for collaboration in accomplishing the experiments in this study.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors state that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ismail, N.R., Abdulwahid, M.Y. & Omar, H.M. Using Sandstone as a Construction Material from Injana Formation, Koya Area, Kurdistan Region; an Evaluation. Innov. Infrastruct. Solut. 7, 48 (2022). https://doi.org/10.1007/s41062-021-00655-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s41062-021-00655-1