Abstract

Within mechanized tunneling, slurry shields are used for excavations in soils with unstable tunnel face due to the possibility to support the tunnel face with pressurized slurry (bentonite suspension). Two key conditions have to be fulfilled to stabilize a tunnel face. These two conditions are sufficient face support pressure in the excavation chamber and the pressure transfer of slurry excess pressure, exceeding the pore pressure, onto the soil skeleton. In practice, the German standard DIN 4126 [Nachweis der Standsicherheit von Schlitzwänden (Stability analysis of diaphragm walls), Deutsche Institut für Normung, 2013] is usually used to predict this transfer. However, DIN 4126 (2013) cannot explain increased pore water pressures measured in practice close to the slurry supported tunnel face during excavation. The increased pore water pressures reduce the efficiency of slurry face support. These pressures are explained by on-going disturbance of the pressure transfer mechanism by periodic rotating cutting tools. The characteristics of disturbance are designated as excavation scale. Another factor of influence is the timespan during which the pressure transfer mechanism can achieve a significant decrease in its own permeability, and thereby to decrease considerably the flow through the tunnel face. By scale comparison of these two processes, a prognosis about occurrence of increased pore water pressures in saturated sands can be derived. It turns out that the different combinations of penetration rate and revolutions per minute of the cutting wheel, while keeping the advance rate constant, would result in different chance for causing increased pore pressures. Consequently, an excavation strategy for reducing the chance for increased pore pressures is suggested with respect to three reference slurry shields.

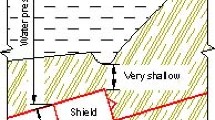

(modified from [12]), Δp represents the slurry excess pressure

Similar content being viewed by others

References

Maidl B et al (2012) Mechanised shield tunnelling. Wilhelm Ernst & Sohn Verlag, Berlin

DAUB (2011) Recommendations for selecting tunnel boring machines/Empfehlungen zur Auswahl von Tunnelvortriebsmaschinen, Taschenbuch für den Tunnelbau. VGE Verlag GmbH, Essen

Figures adapted from https://www.herrenknecht.de

Morgenstern N, Amir-Tahmasseb I (1965) The stability of a slurry trench in cohesionless soils. Geotechnique 15(4):387–395

Weiss F (1967) Die Standfestigkeit flüssigkeitsgestützter Erdwände, PhD thesis, Technische Universität, Berlin

Müller-Kirchenbauer H (1972) Stability of slurry trenches. Proceedings of 5th European conference on soil mechanics and foundation engineering, Madrid, pp 543–553

Talmon AM, Mastbergen DR, Huisman M (2013) Invasion of pressurized clay suspensions into granular soil. J Porous Media 16:351–365

Xu T, Bezuijen A, Dias T (2017) Slurry infiltration ahead of slurry TBM’s in saturated sand: laboratory tests and consequences for practice. 9th international symposium on geotechnical aspects of underground construction in soft ground, Sao Paulo

Thienert C, Pulsfort M (2013) Neue Erkenntnisse zur Stützdruckübertragung beim beim Tunnelvortrieb mit flüssigkeitsgestützter Ortsbrust. Tagungs-Bd. zur STUVA-Tagung Forschung + Praxis Stuttgart, vol 45, pp 151–157

Kilchert M, Karstedt J (1984) Standsicherheitsberechnungen von Schlitzwänden nach DIN 4126. Bd. 2. DIN Deutsches I. Normung EV (ed) Beuth Verlag GmbH Köln, Berlin

König D, Schröder T (2015) Zusammensetzung des Filterkuchens an Schlitzwandlamellen mit kurzer und langer Standzeit. Bauingenieur 90:63–70

Thienert C (2011) Zementfreie Mörtel für die Ringspaltverpressung beim Schildvortrieb mit flüssigkeitsgestützer Ortsbrust, PhD thesis Bergische Universität, Wuppertal

Jacob E (1975) Der Bentonitschild, Technologie und erste Anwendung in Deutschland. Tagungs-Bd. zur STUVA-Tagung Forschung + Praxis Stuttgart, vol 19, pp 30–38

Krause T (1987) Schildvortrieb mit flüssigkeits-und erdgestützter Ortsbrust, Dissertation, Technische Universität Carolo-Wilhelmina, Braunschweig

Anheuser L (1987) Tunnelvortriebsanlagen mit flüssigkeitsgestützter Ortsbrust. Bautechnik 64(11):361–370

Anheuser L (1989) Beispiele zur Bewältigung schwieriger Vortriebsphasen bei Schilden mit flüssigkeitsgestützter Ortsbrust. Tagungs-Bd. zur STUVA-Tagung Forschung + Praxis, vol 32, pp 43–47

Babendererde S (1991) Tunneling machines in soft ground: a comparison of slurry and EPB shield systems. Tunn Undergr Space Technol 6(2):169–174

Jancsecz S, Steiner W (1994) Face support for a large mix-shield in heterogenous ground conditions. In: Proc tunnelling ‘94. Chapman and Hall, London, pp 531–550

Maidl B, Herrenknecht M, Anheuser L (1995) Maschineller Tunnelbau im Schildvortrieb. Wilhelm Ernst & Sohn Verlag, Berlin

Broere W, van Tol A (2000) Influence of infiltration and groundwater flow on tunnel face stability. In: Kusakabe O, Fujita K, Miyazaki Y (eds) Geotechnical aspects of underground construction in soft ground, Tokyo, pp 339–344

Zizka Z, Schoesser B, Popovic I, Thewes M (2017) Excess pore pressures in front of the tunnel face during slurry shield excavations due to different time scales for excavation sequence of cutting tools and penetration time of support fluid. In proceeding of the ECONAS conference EURO: TUN, Innsbruck

DIN 4126 (2013) Nachweis der Standsicherheit von Schlitzwänden (Stability analysis of diaphragm walls), Deutsche Institut für Normung. Berlin

Bezuijen A, Pruiksma JP, van Meerten HH (2001) Pore pressures in front of tunnel, measurements, calculations and consequences for stability of tunnel face. In: Adachi T, Tateyama K, Kimura M (eds) Modern tunneling science and technology. Balkema, Rotterdam, pp 1799–1804

Aime R, Aristaghes P, Autuori P, Minec S (2004) 15 m diameter tunneling under Netherlands polders. Proc. WTC Singapore—under-ground space for sustainable urban development, Elsevier, pp 1–8

Wendl K, Thuro K (2011) “Influence of slurry shield drives on the groundwater exemplary shown at two drives in Tyrol”, 18. Tagung für Ingenieurgeologie und Forum “Junge Ingenieurgeologen”, Berlin

Klitzen J, Herdina J (2016) Hydroshield drive with a diameter of 13 m in the lower inn valley—project design and experience from construction of contract H3-4. Geomech Tunn 9(5):534–546. https://doi.org/10.1002/geot.201600036

Bezuijen A et al (2016) Monitoring pressures and deformations around a TBM. In: 13th international conference underground construction Prague, Prague, Czech Republic

Zizka Z, Schoesser B, Thewes M (2017) Excavation cycle dependent changes of hydraulic properties of granular soil at the tunnel face during slurry shield excavations. In: 9th international symposium on geotechnical aspects of underground construction in soft ground, Sao Paulo

Fattah MY, Mustafa FS (2017) Development of excess pore water pressure around piles excited by pure vertical vibration. Int J Civ Eng 15:907–920

Burger W (2006) Cutterheads for soft ground—principles and design aspects. Tunnel 2:8–19

Köppl F, Thuro K, Thewes M (2015) Factors with an influence on the wear to excavation tools in hydroshield tunnelling in soft ground. Geomech Tunn 8(3):248–257

Thewes M, Schoesser B, Zizka Z (2016) Transient face support in slurry shield tunneling due to different time scales for excavation sequence of cutting tools and penetration time of support fluid. Proceedings of the ITA world tunnel congress

Köppl F (2014) Abbauwerkzeugverschleiß und empirische Verschleißprognose beim Vortrieb mit Hydroschild TVM in Lockergesteinen, Dissertation, Technische Universität München

Köhler M, Maidl U, Martak L (2011) Abrasiveness and tool wear in shield tunnelling in soil. Geomech Tunn 4(1):36–54

Bear J (1988) Dynamics of fluids in porous media. Dover Publications Inc., New York

Häfner F et al (2009) Durchlässigkeitsmessung—Praktikum Geoströmungstechnik. Institut für Bohrtechnik und Fluidbergbau, Technische Universität Bergakademie Freiberg, Freiberg

Coussy O (2004) Poromechanics. Wiley, West Sussex

Herzig JP et al (1970) Flow of suspensions through porous media—application to deep bed filtration. ACS Ind Eng Chem Res 62(5):8–35

DIN 18130-1 (1998) Bestimmung des Wasserdurchlässigkeitsbeiwerts, Teil 1: Laborversuche (determination of permeability coefficient, part 1: laboratory experiments). Deutsches Institut für Normung, Berlin

AFTES Recommendations—Longchamp P (2005) AFTES recommendations concerning slurry for use in slurry shield TBM. Tunnels et Ouvrages Souterrains 1:164–183

Balhoff M (2000) Modeling the flow of non-Newtonian fluids in packed beds at the pore scale. Dissertation, Louisiana State University

Barr DW (2001) Coefficient of permeability determined by measurable parameters. Groundwater 39(3):356–361

DIN 4127 (2014) Erd-und Grundbau—Prüfverfahren für Stützflüssigkeiten im Schlitzwandbau und für deren Ausgangsstoffe (earthworks and foundation engineering—test methods for supporting fluids used in the construction of diaphragm walls and their constituent products). Deutsches Institut für Normung, Berlin

API 13B-1 (1997) Recommended practice standard procedure for field testing water-based drilling fluids, American Petroleum Institute, Washington

Xu T, Bezuijen A (2016) Slurry infiltration tests for slurry shield tunnelling in saturated sands. In: 13th international conference underground construction Prague, Prague, Czech Republic

Acknowledgements

In this paper, the results from the subproject A6 “Locally transient face support within hydro-shields” are presented. The subproject A6 is a part of the “Collaborative Research Centre—SFB 837” at Ruhr-University Bochum in Germany founded by DFG (Deutsche Forschungsgemeinschaft).

Author information

Authors and Affiliations

Corresponding author

Additional information

Deceased (12 Oct 2017): Tom Schanz.

Rights and permissions

About this article

Cite this article

Zizka, Z., Schoesser, B., Thewes, M. et al. Slurry Shield Tunneling: New Methodology for Simplified Prediction of Increased Pore Pressures Resulting from Slurry Infiltration at the Tunnel Face Under Cyclic Excavation Processes. Int J Civ Eng 17, 113–130 (2019). https://doi.org/10.1007/s40999-018-0303-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-018-0303-2