Abstract

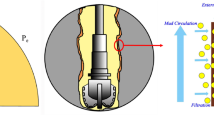

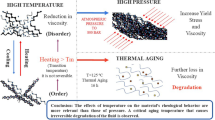

Drilling fluids have rheological and filtration properties, and controlling these properties is essential for the effectiveness of the drilling process. Polymers are developing as one of the most significant additions to drilling fluids among the common additives for controlling these properties. The impact of bentonite treated with natural polymer (P) on the rheological characteristics and fluid loss of WBM was studied. Hence, 208 data of water-based drilling muds were collected from the published articles, and 64 data were obtained experimentally in this investigation considering the concentration of bentonite, polymer, and temperature range of 0–14 wt%, 0–3 wt%, and 25–150 °C, respectively. Temperature effects the rheological properties and fluid loss; while the temperature increased from 25 to 85 °C of 2% bentonite, the initial shear stress decreased by 34%, fluid loss increased by 54%, and mud cake thickness increased by 67% of WBMs. The shear stress and shear strain rate relationships for water-based drilling muds (WBMs) were simulated using Weibull and Vipulanandan rheological models. The modeling results were compared with the Herschel–Bulkley model. Furthermore, the fluid loss relationships for water-based drilling muds (WBMs) were simulated using LSM and Vipulanandan fluid loss models. The modeling results were compared with the API fluid loss model. The results show that the nonlinear model is stronger than the linear model in predicting the shear stress of WBMs as a function of bentonite, polymer, and temperature. Meanwhile, according to several statistical tests, the Weibull and LSM models were more effective in predicting the initial shear stress and fluid loss than other rheological models.

Similar content being viewed by others

Availability of Data and Materials

The data supporting the conclusions of this article are included in the article.

References

Abdo J, Haneef M (2012) Nano-enhanced drilling fluids: pioneering approach to overcome uncompromising drilling problems. J Energy Resour Technol. https://doi.org/10.1115/1.4005244

Abdou MI, El-Sayed Ahmed H (2011) Effect of particle size of bentonite on rheological behavior of the drilling mud. Pet Sci Technol 29(21):2220–2233

Akpan EU, Enyi GC, Nasr GG (2020) Enhancing the performance of xanthan gum in water-based mud systems using an environmentally friendly biopolymer. J Pet Explor Product Technol 10(5):1933–1948

Armaghani DJ, Asteris PG (2021) A comparative study of ANN and ANFIS models for the prediction of cement-based mortar materials compressive strength. Neural Comput Appl 33(9):4501–4532

Armaghani DJ, Mohamad ET, Narayanasamy MS, Narita N, Yagiz S (2017) Development of hybrid intelligent models for predicting TBM penetration rate in hard rock condition. Tunn Undergr Space Technol 63:29–43

Armaghani DJ, Harandizadeh H, Momeni E, Maizir H, Zhou J (2021) An optimized system of GMDH-ANFIS predictive model by ICA for estimating pile bearing capacity. Artif Intell Rev. https://doi.org/10.1007/s10462-021-10065-5

Aybar HS, Sharifpur M, Azizian MR, Mehrabi M, Meyer JP (2015) A review of thermal conductivity models for nanofluids. Heat Transf Eng 36(13):1085–1110

Bayat AE, Shams R (2019) Appraising the impacts of SiO2, ZnO and TiO2 nanoparticles on rheological properties and shale inhibition of water-based drilling muds. Colloids Surf A Physicochem Eng Asp 581:123792

Bol GM (1986) Bentonite quality and quality-evaluation methods. SPE Drill Eng 1(04):288–296

Bourgoyne AT, Millheim KK, Chenevert ME, Young FS (1986) Applied drilling engineering, vol 2. Society of Petroleum Engineers, Richardson, p 514

Cai J, Wu X, Gu S (2011) Successful practices of environmental LG vegetable gum in horizontal directional drilling. In: ICPTT 2011: sustainable solutions for water, sewer, gas, and oil pipelines, pp 2088–2098

Chen H, Asteris PG, Jahed Armaghani D, Gordan B, Pham BT (2019) Assessing dynamic conditions of the retaining wall: developing two hybrid intelligent models. Appl Sci 9(6):1042

Davoodi S, Ahmad Ramazani SA, Soleimanian A, Jahromi AF (2019) Application of a novel acrylamide copolymer containing highly hydrophobic comonomer as filtration control and rheology modifier additive in water-based drilling mud. J Pet Sci Eng 180:747–755

Dias FTG, Souza RR, Lucas EF (2015) Influence of modified starches composition on their performance as fluid loss additives in invert-emulsion drilling fluids. Fuel 140:711–716

Falode OA, Ehinola OA, Nebeife PC (2008) Evaluation of local bentonitic clay as oil well drilling fluids in Nigeria. Appl Clay Sci 39(1–2):19–27

Galindo KA, Zha W, Zhou H, Deville JP (2015a) High temperature, high performance water-based drilling fluid for extreme high temperature wells. In: SPE international symposium on oilfield chemistry

Galindo KA, Zha W, Zhou H, Deville JP (2015b) High temperature, high performance water-based drilling fluid for extreme high temperature wells. In: SPE international symposium on oilfield chemistry. OnePetro

Gerogiorgis DI, Clark C, Vryzas Z, Kelessidis VC (2015) Development and parameter estimation for a multivariate Herschel-Bulkley rheological model of a nanoparticle-based smart drilling fluid. In: Computer aided chemical engineering, vol 37. Elsevier, Amsterdam, pp 2405–2410

Guven N, Panfil DJ, Carney LL (1988) Comparative rheology of water-based drilling fluids with various clays. In: International meeting on petroleum engineering. Society of Petroleum Engineers

Hamad BA, He M, Xu M, Liu W, Mpelwa M, Tang S, Jin L, Song J (2020) A novel amphoteric polymer as a rheology enhancer and fluid-loss control agent for water-based drilling muds at elevated temperatures. ACS Omega 5(15):8483–8495

Hasanipanah M, Monjezi M, Shahnazar A, Armaghani DJ, Farazmand A (2015) Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 75:289–297

Hassani SS, Amrollahi A, Rashidi A, Soleymani M, Rayatdoost S (2016) The effect of nanoparticles on the heat transfer properties of drilling fluids. J Pet Sci Eng 146:183–190

Kelessidis VC, Tsamantaki C, Dalamarinis P (2007) Effect of pH and electrolyte on the rheology of aqueous Wyoming bentonite dispersions. Appl Clay Sci 38(1–2):86–96

Kelessidis VC, Zografou M, Chatzistamou V (2013) Optimization of drilling fluid rheological and fluid loss properties utilizing PHPA polymer. In: SPE middle east oil and gas show and conference. OnePetro

Kosynkin DV, Ceriotti G, Wilson KC, Lomeda JR, Scorsone JT, Patel AD, Friedheim JE, Tour JM (2012) Graphene oxide as a high-performance fluid-loss-control additive in water-based drilling fluids. ACS Appl Mater Interfaces 4(1):222–227

Li C, Zhou J, Armaghani DJ, Li X (2021) Stability analysis of underground mine hard rock pillars via combination of finite difference methods, neural networks, and Monte Carlo simulation techniques. Undergr Space 6(4):379–395

Mahasneh MA, Saleh SK (2012) Evaluation of Jordanian bentonite performance for drilling fluid applications. Contemp Eng Sci 5(3):149–170

Mahmood W, Mohammed A, Ghafor K (2019) Viscosity, initial shear stress and compressive strength of cement-based grout modified with polymers. Results Mater 4:100043

Mahto V, Sharma VP (2004) Rheological study of a water-based oil well drilling fluid. J Pet Sci Eng 45(1–2):123–128

Mahto V, Sharma VP (2005) Tragacanth gum: an effective oil well drilling fluid additive. Energy Sources 27(3):299–308

Mihalakis TS, Makri P, Kelessidis VC, Christidis G, Foscolos A, Papanikolaou K (2004) Improving rheological and filtration properties of drilling muds with addition of greek lignite. In: 7th National congress on soil mechanics, pp 24–26

Mohammed A, Vipulanandan C (2018) Smart cement compressive piezoresistive, stress-strain, and strength behavior with nanosilica modification. J Test Eval 47(2):1479–1501

Momeni E, Nazir R, Armaghani DJ, Maizir H (2014) Prediction of pile bearing capacity using a hybrid genetic algorithm-based ANN. Measurement 57:122–131

Mostafa BA, Assaad FF, Attia M (2007) Rheological and electrical properties of Egyptian bentonite as a drilling mud. J Appl Polym Sci 104(3):1496–1503

Murtaza M, Tariq Z, Zhou X, Al-Shehri D, Mahmoud M, Kamal MS (2021) Okra as an environment-friendly fluid loss control additive for drilling fluids: experimental and modeling studies. J Pet Sci Eng 204:108743

Omole O, Malomo S, Akande S (1989) The suitability of Nigerian black soil clays as drilling mud clays, I. Nature and technical properties. Appl Clay Sci 4(4):357–372

Parsajoo M, Armaghani DJ, Mohammed AS, Khari M, Jahandari S (2021) Tensile strength prediction of rock material using non-destructive tests: a comparative intelligent study. Transp Geotech 31:100652

Peers RA, Holme KR, Tung MA, Williamson WT (1987) Drilling fluid shear stress overshoot behavior. Rheol Acta 26(5):447–452

Pham BT, Nguyen MD, Nguyen-Thoi T, Ho LS, Koopialipoor M, Quoc NK, Van Le H (2021) A novel approach for classification of soils based on laboratory tests using Adaboost, tree and ANN modeling. Transp Geotech 27:100508

Quan H, Li H, Huang Z, Zhang T, Dai S (2014) Copolymer SJ-1 as a fluid loss additive for drilling fluid with high content of salt and calcium. Int J Polym Sci 2014:1–7

Reilly SI, Vryzas Z, Kelessidis VC, Gerogiorgis DI (2016) First-principles rheological modelling and parameter estimation for nanoparticle-based smart drilling fluids. In: Computer aided chemical engineering, vol 38. Elsevier, Amsterdam, pp 1039–1044

Salih A (2022) Multiscale approaches including ANN and M5P-tree with SI and OBJ assessment tools to predict the shear thinning of bentonite drilling muds modified with clay nanosize at various elevated temperatures. International J Geomech 22(1):04021246

Salih A, Rafiq S, Mahmood W, Hind AD, Noaman R, Ghafor K, Qadir W (2020) Systemic multiscale approaches to predict the flowability at various temperature and mechanical properties of cement paste modified with nano-calcium carbonate. Constr Build Mater 262:120777

Sharma MM, Zhang R, Chenevert ME, Ji L, Guo Q, Friedheim J (2012) A new family of nanoparticle based drilling fluids. In: SPE annual technical conference and exhibition. OnePetro

Singh PK, Sharma VP (1991) Effect of additives and aging on the rheological properties of water-based drilling fluid. Energy Sources 13(3):369–387

Srivatsa JT, Ziaja MB (2011) An experimental investigation on use of nanoparticles as fluid loss additives in a surfactant-polymer based drilling fluids. In: International petroleum technology conference. OnePetro

Tahr Z, Mohammed A, Ali JA (2022a) Surrogate models to predict initial shear stress of clay bentonite drilling fluids incorporated with polymer under various temperature conditions. Arab J Geosci 15(17):1–20

Tahr Z, Mohammed A, Ali JA (2022b) Surrogate models to predict initial shear stress of clay bentonite drilling fluids incorporated with polymer under various temperature conditions. Arab J Geosci 15:1449. https://doi.org/10.1007/s12517-022-10720-3

Tehrani MA, Popplestone A, Swaco MI, Guarneri A, Carminati S (2007) Water-based drilling fluid for HT/HP applications. In: Presented at the international symposium on oilfield chemistry, pp 1–10

Temraz MG, Hassanien I (2012) Evaluation of some egyptian shales as a drilling fluid additive. Energy Sources Part A Recovery Util Environ Effects 34(6):549–558

Tong H, Wu X (2009) Laboratory study of disaccharide organic compound drilling fluid for trenchless technology. In: ICPTT 2009: advances and experiences with pipelines and trenchless technology for water, sewer, gas, and oil applications, pp 1910–1917

Versan Kok M, Alikaya T (2003) Rheological evaluation of polymers as drilling fluids. Pet Sci Technol 21(1–2):113–123

Vipulanandan C, Mohammed A (2015a) Effect of nanoclay on the electrical resistivity and rheological properties of smart and sensing bentonite drilling muds. J Pet Sci Eng 130:86–95

Vipulanandan C, Mohammed A (2015b) Smart cement modified with iron oxide nanoparticles to enhance the piezoresistive behavior and compressive strength for oil well applications. Smart Mater Struct 24(12):125020

Vipulanandan C, Mohammed A (2015c) Smart cement rheological and piezoresistive behavior for oil well applications. J Pet Sci Eng 135:50–58

Vipulanandan C, Mohammed A (2020a) Effect of drilling mud bentonite contents on the fluid loss and filter cake formation on a field clay soil formation compared to the API fluid loss method and characterized using Vipulanandan models. J Pet Sci Eng 189:107029

Vipulanandan C, Mohammed A (2020b) Magnetic field strength and temperature effects on the behavior of oil well cement slurry modified with iron oxide nanoparticles and quantified with vipulanandan models. J Test Eval 48(6):4516–4537

Vipulanandan C, Mohammed A (2020c) Zero fluid loss, sensitivity and rheological properties of clay bentonite (WBM) modified with nanoclay quantified using Vipulanandan models. Upstream Oil Gas Technol 5:100012

Vipulanandan C, Mohammed A, Samuel RG (2017) Smart bentonite drilling muds modified with iron oxide nanoparticles and characterized based on the electrical resistivity and rheological properties with varying magnetic field strengths and temperatures. In: Offshore technology conference. OnePetro

Warren B, van der Horst P, Stewart W (2003) Application of amphoteric cellulose ethers in drilling fluids. In: International symposium on oilfield chemistry. OnePetro

Zekri A (1994) Assessment of temperature effects on water base mud properties. Oil Gas (hamburg) 20(2):32–34

Acknowledgements

The University of Soran, College of Engineering, Petroleum Engineering- supported this work. The authors thank Petrochem (https://www.petrocheme.com/) for their support during the study.

Funding

This work had no funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics Approval and Consent to Participate

Not applicable.

Consent for Publication

I (Zanwer) hereby declare that I participated in this study and the manuscript's development models. I have read the final version and consent for the article to be published in this Journal.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tahr, Z., Mohammed, A.S. & Ali, J.A. Efficient Models to Evaluate the Effect of Temperature on the Water Loss, Filter Cake, and Yield Stress of Polymerized Clay Bentonite Using in the Oil Well Drilling Operation. Iran J Sci Technol Trans Civ Eng 47, 1089–1107 (2023). https://doi.org/10.1007/s40996-022-00972-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-022-00972-0