Abstract

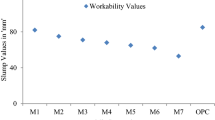

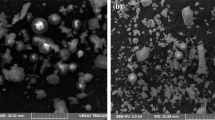

The present experimental study aims to develop the geopolymer concrete under ambient curing. The replacement of 15%, 20% and 25% fly ash with ground granulated blast furnace slag (GGBS) and the addition of 5%, 10% and 15% of glass powder have been done and cured under ambient curing. The incorporation of GGBS and glass powder has been done to enhance the reactivity of geopolymer matrix. In addition to this, the study aims at gauging the effect of different molar concentration, i.e., 4 M, 8 M and 12 M on the mixes prepared and in turn deciding the optimum molar concentration for preparation of the mixes. It has been found that the control mix containing only fly ash has developed lesser strength as compared to all the other blended mixes. It is also observed that samples S25–G5–M4 (highest percentage of GGBS) developed the highest strength. The SEM–EDS test results also show that the formation of a dense network of geopolymerization product in the microstructure is the possible reason for the higher strength of S25–G5–M4 as compared to the other mixes.

Similar content being viewed by others

References

Alonso S, Palomo A (2001) Alkaline activation of metakaolin and calcium hydroxide mixtures: influence of temperature, activator concentration and solids ratio. Mater Lett 47:55–62

Bakharev T (2006) Thermal behaviour of geopolymers prepared using Class F fly ash and elevated temperature curing. Cem Concr Res 36:1134–1147

Castel A, Foster SJ, Ng T, Sanjayan JG, Gilbert RI (2016) Creep and draying shrinkage of a blended slag and low calcium fly ash geopolymer concrete. Mater Struct 49:1619–1628

Cheng WT, Chiu JP (2003) Fire-resistant geopolymer produced by granulated blast furnace slag. Miner Eng 16:205–210

Chindaprasirt P, De Silva P, Sagoe-Crentsil K, Hanjitsuwan S (2012) Effect of SiO2 and Al2O3 on the setting and hardening of high calcium fly ash-based geopolymer systems. J Mater Sci 47(12):4876–4883. https://doi.org/10.1007/s10853-012-6353-y

Collins F, Sanjayan JG (2000) Effect of pore size distribution on drying shrinkage of alkali activated slag concrete. Cem Concr Res 30(9):1401–1406

Criado M, Palomo A, Fernandez-Jimenez A (2005) Alkali activation of fly ashes. Part 1: effect of curing conditions on the carbonation of the reaction products. Fuel 84:2048–2054

Deb PS, Nath P, Sarkar PK (2014) The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater Des 62:32–39

Diaz EI, Allouche EN, Eklund S (2010) Factors affecting the suitability of fly ash as source material for geopolymers. Fuel 89(5):992–996

Duxon P, Fernandez-Jiminez A, Provis JL, Luckey GC, Palomo A, Van Deventure JSJ (2007) Geopolymer technology: the current state of the art. J Mater Sci 2007(42):2917–2933

Gao X, Yu QL, Brouwers HJH (2015) Reaction kinetics, gel character and strength of ambient temperature cured alkali activated slag–fly ash blends. Constr Build Mater 80:105–115

Guo X, Shi H, Dick WA (2010) Compressive strength and microstructural characteristics of class C fly ash geopolymer. Cem Concr Compos 32(2):142–147

http://www.worldcement.com/news/cement/articles/Cement_India_demand_price_capacity_160.aspx#.UoIUv3DItSk, 12 Nov 2013

IS:516-1959: (Reaffirmed 2004) Methods of test for strength of concrete, Bureau of Indian Standard, New Delhi, 2004

IS:5816-1999: Methods of test for splitting tensile strength of concrete, Bureau of Indian Standard, New Delhi, 1999

Ken PW, Ramli M, Ban CC (2015) An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Constr Build Mater 77:370–395

Komljenović M, Bascarevic Z, Bradic V (2010) Mechanical and microstructural properties of alkali-activated fly ash geopolymers. J Hazard Mater 181:35–42

Kovalchuk G, Fernandez-Jimenez A, Palomo A (2007) Alkali-activated fly ash: effect of thermal curing conditions on mechanical and microstructural development—part II. Fuel 86:315–322

Lee WKW, van Deventer JSJ (2002) The effect of ionic contaminants on the early-age properties of alkali-activated fly ash-based cements. Cem Concr Res 32(4):577–584

Li X, Wang Z, Jiao Z (2013) Influence of curing on the strength development of calcium-containing geopolymer mortar. Materials 6:5069–5076

Pascual AB, Tognonvi MT, Tagnit-Hamou A (2014) Waste glass powder-based alkali-activated mortar. Int J Res Eng Technol 3(13):15–19

Puertas F, Martı́nez-Ramı́rez S, Alonso S, Vazquez T (2000) Alkali-activated fly ash/slag cement strength behaviour and hydration products. Cem Concr Res 30:1625–1632

Rashidian-Dezfouli H, Rangaraju PR (2017a) Comparison of strength and durability characteristics of a geopolymer produced from fly ash, ground glass fiber and glass powder. Materi Constr 67(328):136

Rashidian-Dezfouli H, Rangaraju PR (2017b) A comparative study on the durability of geopolymers produced with ground glass fiber, fly ash, and glass-powder in sodium sulfate solution. Constr Build Mater 153:996–1009

Rashidian-Dezfouli H, Rangaraju PR, Kothala VSK (2018) Influence of selected parameters on compressive strength of geoploymer produced from ground glass fiber. Constr Build Mater 162:393–405

Rattanasak U, Chindaprasirt P (2009) Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner Eng 22(12):1073–1078

Rattanasak U, Pankhet K, Chindapraist P (2011) Effect of chemical admixtures on properties of high calcium fly ash geopolymer. Int J Miner Metall Mater 18(3):364–369

Singh B, Ishwarya G, Gupta M, Bhattacharyya SK (2015) Geopolymer concrete: a review of some recent developments. Constr Build Mater 85:78–90

Sukmak P, Horpibulsuk S, Shen S-L (2013) Strength development in clay–fly ash geopolymer. Constr Build Mater 40:566–574

Temuujin J, van Riessen A, Williams R (2009) Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J Hazard Mater 167(1–3):82–88

Turner LK, Collins FG (2013) Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete. Constr Build Mater 43:125–130

Yip CK, van Deventer JSJ (2003) Microanalysis of calcium silicate hydrate gel formed within a geopolymeric binder. J Mater Sci 38(18):3851–3860. https://doi.org/10.1023/a:1025904905176

Yip CK, Lukey GC, van Deventer JSJ (2005) The coexistence of geopolymeric gel and calcium silicate hydrate at the early stage of alkaline activation. Cem Concr Res 35(9):1688–1697. https://doi.org/10.1016/j.cemconres.2004.10.042

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sethi, H., Bansal, P.P. & Sharma, R. Effect of Addition of GGBS and Glass Powder on the Properties of Geopolymer Concrete. Iran J Sci Technol Trans Civ Eng 43, 607–617 (2019). https://doi.org/10.1007/s40996-018-0202-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40996-018-0202-4