Abstract

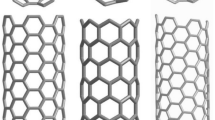

The growth process of carbon nanotubes (CNTs) by chemical vapor deposition is modeled using multilayered perceptron artificial neural networks technique. The model was trained using six growth parameters. Numerous values for these parameters were gathered from published articles. The six growth parameters were catalyst thickness, pressure of acetylene gas, temperature and time of pretreatment and growth process. These parameters were used as input data for the determination of the CNTs’ diameter as the output of the model. Experiments were run using the predicted output value, and the synthesized CNTs were evaluated by scanning electron microscopy and transmission electron microscopy. The grown CNTs were multiwall with a bamboo structure and tip-growth mechanism. Comparison between the model prediction and the experimental results showed a remarkable agreement with an insignificant error (approximately 7%). X-ray diffraction and Raman spectrometer analysis results showed that with increasing temperature and time of pretreatment, the structural defects of CNTs were reduced, and the purity and thus field emission properties will be increased.

Similar content being viewed by others

References

Banda S (2002) Characterization of aligned carbon nanotube/polymer composites. Jawaharlal Nehru Technological University, Hyderabad

Chen M, Chen CM, Chen CF (2002) Growth of carbon nanotubes by microwave plasma chemical vapor deposition using CH4 and CO2 gas mixture. Thin Solid Films 420–421:230–234

Chew SY, Ng SH, Wang J, Novak P, Krumeich F, Chou SL et al (2009) Flexible freestanding carbon nanotube films for model lithium-ion batteries. Carbon 47:2976–2983

Chiangga S, Suttisiri N, Nilsaengrat P (2009) Effect of temperature on carbon nanotubes growth on thin Iron film by thermal chemical vapor deposition method under the low pressure. Phys Procedia 2:107–111

Choi YC, Kim DW, Lee TJ, Lee CJ, Lee YH (2001) Growth mechanism of vertically aligned carbon nanotubes on silicon substrates. Synth Met 117:81–86

Choi HY, Chang WS, Kim HS, Park YH, Kim JU (2006) Acquisition of X-ray images by using a CNT cold emitter. Phys Lett A 357:36–41

Ćirović V, Aleksendrić D (2010) Development of neural network model of disc brake operation. FME Trans 38:29–38

Di JT, Yong ZZ, Yang XJ, Li QW (2011) Structural and morphological dependence of carbon nanotube arrays on catalyst aggregation. Appl Surf Sci 258:13–18

Fratini L, Buffa G, Palmeri D (2009) Using a neural network for predicting the average grain size in friction stir welding processes. Comput Struct 87:1166–1174

Khorsand H, Siadati MH, Ganjeh E, Khorshayan M (2015) Technical knowledge development and manufacture of multi-purpose rapid radiation heat treatment tube furnaces with ability to rotational spin, Iranian Patent number 84830

Huang CS, Yeh CY, Yuan CH, Huang BR, Hsiao CH (2009) The study of a carbon nanotube O2 sensor by field emission treatment. Diam Relat Mater 18:461–464

Huh Y, Lee JY, Lee JH, Lee TJ, Lyu SC, Lee CJ (2003) Selective growth and field emission of vertically well-aligned carbon nanotubes on hole-patterned silicon substrates. Chem Phys Lett 375:388–392

Huh Y, Green MLH, Lee CJ (2006) Cross-sectional transmission electron microscopic study on the initial stage growth of carbon nanotubes. Diam Relat Mater 15:239–243

Jeng KT, Chien CC, Hsu NY, Huang WM, Chiou SD, Lin SH (2007) Fabrication and impedance studies of DMFC anode incorporated with CNT-supported high-metal-content electrocatalyst. J Power Sources 164:33–41

Jeong N, Seo Y, Lee J (2007) Vertically aligned carbon nanotubes synthesized by the thermal pyrolysis with an ultrasonic evaporator. Diam Relat Mater 16:600–608

Jeonga GH, Olofssona N, Falk LKL, Campbell EEB (2009) Effect of catalyst pattern geometry on the growth of vertically aligned carbon nanotube arrays. Carbon 47:696–704

Karimzadeh F, Ebnonnasir A, Foroughi A (2006) Artificial neural network modeling for evaluating of epitaxial growth of Ti6Al4V weldment. Mater Sci Eng A 432:184–190

Katara SL, Hernandez D, Labiosa AB, Vargas EM, Fonseca L, Weiner B et al (2010) SiN/bamboo like carbon nanotube composite electrodes for lithium ion rechargeable batteries. Electrochim Acta 55:2269–2274

Khorsand H, Arjomandi M, Abdoos H, Sadati SH (2008) Application of artificial neural network for prediction of heat treated sintered steels properties. Defect Diffus Forum 273–276:323–328

Kramer A, Radde N (2010) Towards experimental design using a Bayesian framework for parameter identification in dynamic intracellular network models. Procedia Comput Sci 1:1645–1653

Kunadian I, Andrews R, Menguc MP, Qiana D (2009) Thermoelectric power generation using doped MWCNTs. Carbon 47:589–601

Lee CJ, Lyu SC, Cho YR, Lee JH, Cho KI (2001a) Diameter-controlled growth of carbon nanotubes using thermal chemical vapor deposition. Chem Phys Lett 341:245–249

Lee CJ, Park J, Huh Y, Lee JY (2001b) Temperature effect of the growth of carbon nanotube using thermal chemical vapor deposition. Chem Phys Lett 343:33–38

Lee BJ, Kim JJ, Shin EC, Jeong GH (2011) Growth optimization of double-walled carbon nanotubes yielding precisely designed structures. Met Mater Int 17:309–314

Liu H, Cheng G, Zheng R, Zhao Y, Liang C (2006) Layered growth of aligned carbon nanotubes arrays on silicon wafers. J Mol Catal A Chem 247:52–57

Liu H, Cheng GA, Zheng R, Zhao Y, Liang C (2008) Effects of the restructuring of Fe catalyst films on chemical vapor deposition of carbon nanotubes. Surf Coat Technol 202:3157–3163

Minett A, Fraysse J, Gang G, Kim GT, Roth S (2002) Nanotube actuators for nanomechanics. Curr Appl Phys 2:61–64

O’Connell MJ (2006) Carbon nanotubes: properties and applications. CRC Press, New York

Okuyucu H, Kurt A, Arcaklioglu E (2007) Artificial neural network application to the friction stir welding of aluminum plates. Mater Des 28:78–84

Pakdee U, Suttisiri N, Hoonnivathana E, Chiangga S (2007) Synthesis of carbon nanotubes and nanobelts on thin iron film by thermal chemical vapor deposition method. Kasetsart J (Nat Sci) 41:173–177

Paradise M, Goswami T (2007) Carbon nanotubes—production and industrial applications. Mater Des 28:1477–1489

Park JB, Choi GS, Cho YS, Hong SY, Kim D, Choi SY, Lee JH, Cho KI (2002) Characterization of Fe-catalyzed carbon nanotubes grown by thermal chemical vapor deposition. J Cryst Growth 244:211–217

Radhakrishnan JK, Pandian PS, Padaki VC, Bhusan H, Rao KUB, Xie J, Abraham JK, Varadan VK (2009) Growth of multiwalled carbon nanotube arrays by chemical vapour deposition over iron catalyst and the effect of growth parameters. Appl Surf Sci 255:6325–6334

Rashidi AM, Eivani AR, Amadeh A (2009) Application of artificial neural networks to predict the grain size of nano-crystalline nickel coatings. Comput Mater Sci 45:499–504

Rizzo A, Rossi R, Signore MA, Piscopiello E, Capodieci L, Pentassuglia R, Dikonimos T, Giorgi R (2008) Effect of Fe catalyst thickness and C2H2/H2 flow rate ratio on the vertical alignment of carbon nanotubes grown by chemical vapour deposition. Diam Relat Mater 17:1502–1505

Siegal MP, Miller PA, Provencio PP, Tallant DR (2007) Controlled growth of carbon nanotube films for high-current field emission. Diam Relat Mater 16:1793–1798

Sohn JI, Nam C, Lee S (2002) Vertically aligned carbon nanotube growth by pulsed laser deposition and thermal chemical vapor deposition methods. Appl Surf Sci 197–198:568–573

Son SY, Lee Y, Lee DH, Kim SD, Sung SH, Hong SY, Cho SJ (2008) Field emission property of multi-walled carbon nanotubes with different carbon sources in a fluidized bed reactor. Phys Chem Solids 69:1188–1193

Taleshi F (2014) A new strategy for increasing the yield of carbon nanotubes by the CVD method. Fuller Nanotub Carbon Nanostruct 22:921–927

Tanaka K, Yamabe T, Fukui K (1999) The science and technology of carbon nanotubes. Elsevier, Amsterdam

Tu JV (1996) Advantages and disadvantages of using artificial neural networks versus logistic regression for predicting medical outcomes. J Clin Epidemiol 49:1225–1231

Weng TW, Lai YH, Lee KY (2008) Area effect of patterned carbon nanotube bundle on field electron emission characteristics. Appl Surf Sci 254:7755–7758

Yao Y, Falk LKL, Morjan RE, Nerushev OA, Campbell EEB (2004) Synthesis of carbon nanotube films by thermal CVD in the presence of supported catalyst particles, part II: the nanotube film. J Mater Sci Mater Electron 15:583–594

Zhang C, Pisana S, Wirth CT, Parvez A, Ducati C, Hofmann S et al (2008) Growth of aligned millimeter-long carbon nanotube by chemical vapor deposition. Diam Relat Mater 17:1447–1451

Acknowledgements

The authors would like to thank Iranian National Science Foundation (INSF) for their financial support of this research (Grant No. 90001088).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abad, S.N.K., Ganjeh, E., Zolriasatein, A. et al. Predicting Carbon Nanotube Diameter Using Artificial Neural Network Along with Characterization and Field Emission Measurement. Iran J Sci Technol Trans Sci 41, 151–163 (2017). https://doi.org/10.1007/s40995-017-0198-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-017-0198-9