Abstract

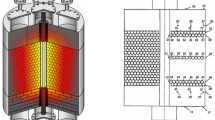

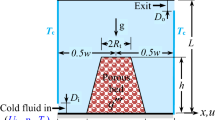

This work presents the development, experimental validation, and application of a control volume element model of 3D finite heat transfer method to optimize a new convective heat system for phytosanitary treatment of wood pallets. A new treatment system consisting of a heat-recovering design for exhaust gases from a distillery boiler is presented. The 3D spatial domains are discretized with hexahedral blocks to modeling and optimize the operational parameters when block-type pallets are treated. Accordingly, an energy balance is applied and the resulting system of differential equations is discretized in time domain to obtain the spatiotemporal temperature profile in the pallet block as critical geometry. The 3D model is adjusted by correlating simulated with experimental data. Overall heat transfer coefficients are obtained. Temperature and treatment time are optimized. Optimal conditions are found for the studied system with air temperature at 80 °C and 137 min treatment time. The thermal efficiency of the new treatment system is found as 9.14% and the index of energy consumption is 0.37 kWh with a cost of 0.53 € per treated pallet at the studied conditions. The economic feasibility of the new treatment system is discussed.

Similar content being viewed by others

References

Allen E, Noseworthy M, Ormsby M (2017) Phytosanitary measures to reduce the movement of forest pests with the international trade of wood products. Biol Invasions 19(11):3365–3376

Bedelean B (2018) Application of artificial neural networks and Monte Carlo method for predicting the reliability of RF phytosanitary treatment of wood. Eur J Wood Wood Prod 76(4):1113–1120

Bergman TL, Bergman TL, Incropera FP, Dewitt DP, Lavine AS (2011) Fundamentals of heat and mass transfer. Wiley, Hoboken

Deviatkin I, Khan M, Ernst E, Horttanainen M (2019) Wooden and plastic pallets: a review of life cycle assessment (LCA) studies. Sustainability 11(20):5750

Erchiqui F, Kaddami H, Slaoui-Hasnaoui F, Koubaa A (2020) 3D finite element enthalpy method for analysis of phytosanitary treatment of wood by microwave. Eur J Wood Wood Prod 78(3):577–591

Frąś J, Olsztyńska I, Scholz S (2018) Standardization and certification of the wooden packaging in international trade. Res Logist Prod 8:25–37

Herrera-Díaz R, Sepúlveda-Villarroel V, Pérez-Peña N, Salvo-Sepúlveda L, Salinas-Lira C, Llano-Ponte R, Ananías RA (2018) Effect of wood drying and heat modification on some physical and mechanical properties of radiata pine. Dry Technol 36(5):537–544

Hughes KA, Misiak M, Ulaganathan Y, Newsham KK (2018) Importation of psychrotolerant fungi to Antarctica associated with wooden cargo packaging. Antarct Sci 30(5):298–305

Ingersoll LR, Zobel OJ, Ingersoll AC (1948) Heat conduction, with engineering and geological applications. McGraw-Hill Book Company, New York

Jeffers AE (2013) Heat transfer element for modelling the thermal response of non-uniformly heated plates. Finite Elem Anal Des 63:62–68

Kim KJ, Ryu JA, Eom TJ (2019) Characteristics of the heat treated wood packaging materials according to international standards for phytosanitary measures and verifiability of heat treatment. Wood Res 64(4):647–658

Kumar D, Mahanta P, Kalita P (2020) Energy and exergy analysis of a natural convection dryer with and without sensible heat storage medium. J Energy Storage. https://doi.org/10.1016/j.est.2020.101481

Kumar D, Mahanta P, Kalita P (2021) Performance analysis of a solar air heater modified with zig-zag shaped copper tubes using energy-exergy methodology. Sustain Energy Technol Assess 46:101222. https://doi.org/10.1016/j.seta.2021.101222

Kumar D, Mahanta P, Kalita P (2022) Performance analysis of a novel biomass-fired grain dryer integrated with thermal storage medium. Biosys Eng 216:65–78. https://doi.org/10.1016/j.biosystemseng.2022.02.001

MacLean JD (1941) Thermal conductivity of wood. Heating, piping & air conditioning, Madison

Nithiarasu P, Lewis RW, Seetharamu KN (2016) Fundamentals of the finite element method for heat and mass transfer. Wiley, Hoboken

Park J, Horvath L, Bush RJ (2018) Life cycle inventory analysis of the wood pallet repair process in the United States. J Ind Ecol 22(5):1117–1126

Pawson SM, Bader MF, Brockerhoff EG, Heffernan WJB, Kerr JL, O’Connor B (2019) Quantifying the thermal tolerance of wood borers and bark beetles for the development of Joule heating as a novel phytosanitary treatment of pine logs. J Pest Sci 92(1):157–171

Pawson SM, Kerr JL, Somchit C, Wardhaugh CW (2020) Flight activity of wood-and bark-boring insects at New Zealand ports. N Z J for Sci. https://doi.org/10.33494/nzjfs502020x132x

Wang, X. (2021). Heat sterilization of wood. In: Chapter 20 in FPL-GTR-282, pp 20–1

Yang S, Pilet TJ, Ordonez JC (2018) Volume element model for 3D dynamic building thermal modelling and simulation. Energy 148:642–661

Acknowledgments

The authors would like to thank the VLIR-UOS project between Belgium and Cuba for providing funding and granting the support of the current and future studies.

Author information

Authors and Affiliations

Contributions

FFC, HCS, and ÁSR conceived and designed the phytosanitary treatment system and wrote the paper; FFC and JLD performed the experiments; FFC, HCS, ÁSR, JY, DV, and RC analyzed the data.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fong Casas, F., Crespo Sariol, H., Sánchez Roca, Á. et al. 3D finite heat transfer method to optimize a hot air convective system for phytosanitary treatment of wood pallets. Energ. Ecol. Environ. 8, 273–287 (2023). https://doi.org/10.1007/s40974-023-00275-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40974-023-00275-8