Abstract

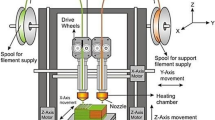

This study aims to compare the fatigue behavior of similar and dissimilar polymer weld joints created after an additive manufacturing process. The fatigue samples were 3D printed in ABS and PLA using a fused filament fabrication printer. Various weld joints, including ABS/ABS, PLA/PLA, and PLA/ABS, were produced utilizing the rotary friction welding process. The fatigue behavior of these joints was evaluated using rotating-beam fatigue testing at various load levels. In addition, fatigue tests were performed on non-welded PLA and ABS samples. The findings revealed that PLA/PLA joints had superior fatigue resistance than non-welded PLA. Furthermore, in this sequence, PLA/PLA, ABS/ABS, and PLA/ABS had the highest fatigue resistance.

Similar content being viewed by others

Availability of data and materials

The data sets used and/or analyzed during the current study are available from the corresponding author on a reasonable request.

Abbreviations

- AM:

-

Additive manufacturing

- PLA:

-

Polylactic acid

- ABS:

-

Acrylonitrile butadiene styrene

- PMMA:

-

Polymethyl methacrylate

- PVC:

-

Polyvinyl chloride

- PA:

-

Polyamide

- PP:

-

Polypropylene

- PE:

-

Polyethylene

- FFF:

-

Fused filament fabrication

- FDM:

-

Fused deposition modeling

- FSW:

-

Friction stir-welding

- FW:

-

Friction welding

- RFW:

-

Rotary friction welding

- NW:

-

No welding or non-welded

- FESEM:

-

Field emission scanning electron microscope

References

Lauwers B, Klocke F, Klink A, Tekkaya AE, Neugebauer R, McIntosh D (2014) Hybrid processes in manufacturing. CIRP Ann 63(2):561–583

Gibson I, Rosen DW, Stucker B, Khorasani M (2021) Additive manufacturing technologies. Springer, Berlin

Kumar R, Singh R, Ahuja I (2019) Mechanical, thermal and micrographic investigations of friction stir welded: 3D printed melt flow compatible dissimilar thermoplastics. J Manuf Process 38:387–395

Tiwary VK, Ravi N, Arunkumar P, Shivakumar S, Deshpande AS, Malik VR (2020) Investigations on friction stir joining of 3D printed parts to overcome bed size limitation and enhance joint quality for unmanned aircraft systems. Proc Inst Mech Eng C J Mech Eng Sci 234(24):4857–4871

Kumar R, Singh R, Ahuja IPS, Amendola A, Penna R (2018) Friction welding for the manufacturing of PA6 and ABS structures reinforced with Fe particles. Compos B Eng 132:244–257

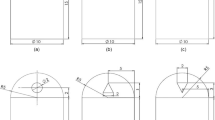

Asghari V, Kami A, Bagheri A (2021) An Investigation on the effect of nanoparticle reinforcement and weld surface shape on bending behavior of rotary friction-welded HDPE. Proc Inst Mech Eng Part L J Mater Des Appl 236(1):222–234

Sweeney CB, Lackey BA, Posposil MJ, Achee TC, Hichks VK, Morgan AG, Teipel BR, Saed MA, Green MJ (2017) Welding of 3D-printed carbon nanotube-polymer composites by locally induced microwave heating. Sci Adv 3(6):e1700262

Langnau L (2016) Ultrasonic welding 3D printed parts. https://www.makepartsfast.com/how-to-ultrasonically-weld-3d-printed-parts/. Accessed 12 Oct 2016

Tiwary VK, Arunkumar P, Malik VR (2021) An overview on joining/welding as post-processing technique to circumvent the build volume limitation of an FDM-3D printer. Rapid Prototyp J 27(4):808–821

Lin C, Wu LC (2000) Friction welding of similar and dissimilar materials: PMMA and PVC. Polym Eng Sci 40(8):1931–1941

Aydin M (2015) Friction weldability of a PA 6 polymer. Mater Test 57(3):214–219

Lin C-B, Wu LC, Chen YY (2004) Friction welding of similar materials: polypropylene, high-density polyethylene, and nylon-6. J Appl Polym Sci 91(5):2771–2780

Bindal T, Saxena RK, Pandey S (2020) Analysis of joint overlap during friction spin welding of plastics. Mater Today Proc 26:2798–2804

Hasegawa M, Asada T, Ozawa Y (2002) Study of friction welding of polyethylene. Weld Int 16(7):537–543

Lin C, Wu L-C, Chou Y-C (2003) Effect of solvent and cosolvent on friction welding properties between part of PMMA with PVC. J Mater Sci 38(12):2563–2570

Singh R, Kumar R, Feo L, Fraternali F (2016) Friction welding of dissimilar plastic/polymer materials with metal powder reinforcement for engineering applications. Compos B Eng 101:77–86

Letcher T, Waytashek M (2014) Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer. In: ASME international mechanical engineering congress and exposition, 2014, vol 46438. American Society of Mechanical Engineers, p V02AT02A014

Afrose MF, Masood SH, Iovenitti P, Nikzad M, Sbarski I (2016) Effects of part build orientations on fatigue behavior of FDM-processed PLA material. Prog Addit Manuf 1(1):21–28

Jerez-Mesa R, Travieso-Rodriguez JA, Llumà-Fuentes J, Gomez-Gras G, Puig D (2017) Fatigue lifespan study of PLA parts obtained by additive manufacturing. Procedia Manuf 13:872–879

Ezeh OH, Susmel L (2018) On the fatigue strength of 3D-printed polylactide (PLA). Procedia Struct Integr 9:29–36

Gomez-Gras G, Jerez-Mesa R, Travieso-Rodriguez JA, Lluma-Fuentes J (2018) Fatigue performance of fused filament fabrication PLA specimens. Mater Des 140:278–285

Lee J, Huang A (2013) Fatigue analysis of FDM materials. Rapid Prototyp J 19(4):291–299

Ziemian CW, Ziemian RD, Haile KV (2016) Characterization of stiffness degradation caused by fatigue damage of additive manufactured parts. Mater Des 109:209–218

Azadi M, Dadashi A, Dezianian S, Kianifar M, Torkaman S, Chiyani M (2021) High-cycle bending fatigue properties of additive-manufactured ABS and PLA polymers fabricated by fused deposition modeling 3D-printing. Forces Mech 3:100016

Safai L, Cuellar JS, Smit G, Zadpoor AA (2019) A review of the fatigue behavior of 3D printed polymers. Addit Manuf 28:87–97

Shu KM, Chang CS, Chuang WJ, Wang SI, Jang YY (2010) Study on application of Taguchi method to ultrasonic-aided spin welding of heterogeneous plastic materials. Adv Mater Res 126–128:381–387

ISO 1143:2010 (2010) Metallic materials—rotating bar bending fatigue testing

Khameneh MJ, Azadi M (2018) Evaluation of high-cycle bending fatigue and fracture behaviors in EN-GJS700-2 ductile cast iron of crankshafts. Eng Fail Anal 85:189–200

Parast MSA, Khameneh MJ, Azadi M, Mahdipanah MH, Roostaie S (2021) Effect of plasma nitriding on high-cycle fatigue properties and fracture behaviors of GJS700 nodular cast iron under cyclic bending loading. Fatigue Fract Eng Mater Struct 44(8):2070–2086

Becker WT, Shipley RJ (2002) ASM handbook: volume 11: failure analysis and prevention. ASM International

Mills K, Davis JR (1987) ASM handbook, volume 12: fractography. ASM International

Ning F, Cong W, Qiu J, Wei J, Wang S (2015) Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos B Eng 80:369–378

Yadollahi A, Shamsaei N (2017) Additive manufacturing of fatigue resistant materials: challenges and opportunities. Int J Fatigue 98:14–31

Zhang W, Srivastava I, Zhu Y-F, Picu CR, Koratkar NA (2009) Heterogeneity in epoxy nanocomposites initiates crazing: significant improvements in fatigue resistance and toughening. Small 5(12):1403–1407

Zolfaghari M, Azadi M, Azadi M (2021) Characterization of high-cycle bending fatigue behaviors for piston aluminum matrix SiO2 nano-composites in comparison with aluminum-silicon alloys. Int J Metalcast 15(1):152–168

Kubit A, Wydrzynski D, Trzepiecinski T (2018) Refill friction stir spot welding of 7075-T6 aluminum alloy single-lap joints with polymer sealant interlayer. Compos Struct 201:389–397

Shen Z, Ding Y, Chen J, Gerlich AP (2016) Comparison of fatigue behavior in Mg/Mg similar and Mg/steel dissimilar refill friction stir spot welds. Int J Fatigue 92:78–86

Azadi M, Dadashi A, Sadegh Aghareb Parast M, Dezianian S, Bagheri A, Kami A, Kianifar M, Asghari V (2022) A comparative study for high-cycle bending fatigue lifetime and fracture behavior of extruded and additive-manufactured 3D-printed acrylonitrile butadiene styrene polymers. Int J Addit Manufact Struct 1(1):1. https://doi.org/10.53964/ijams.2022001

Funding

This article is funded based on a research project (Number: 21420; Date: November 20, 2021) by the Vice Chancellor of Research and Technology in Semnan University, Semnan, Iran.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Ethical approval

Not applicable, because this article does not contain any studies with human or animal subjects.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Parast, M.S.A., Bagheri, A., Kami, A. et al. Bending fatigue behavior of fused filament fabrication 3D-printed ABS and PLA joints with rotary friction welding. Prog Addit Manuf 7, 1345–1361 (2022). https://doi.org/10.1007/s40964-022-00307-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00307-5