Abstract

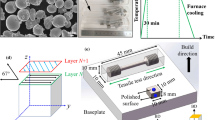

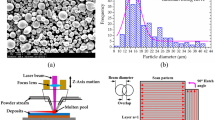

In general, traditionally manufactured steel alloys exhibit a typical elastic plastic deformation distinguished by linear and nonlinear stress–strain curves. However, an unconventional elastic–plastic behavior was observed from the 3D-printed 316L stainless steel specimens in this study, which showed no noticeable hardening in their elastic–near perfect plastic behavior. For comparison, similar tests were also performed on conventionally processed (hot rolled) 316L stainless steel samples. Microhardness indentation, resonant frequency, and tensile test have been performed on both types of samples and the results were compared with the ones available in the literature. Microstructural characteristics of the specimens produced by the two technologies were compared to explain the unconventional elastic–plastic behaviors of the 3D-printed specimens. Optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) were performed for the analysis of microstructural characteristics of the specimens. High concentrations of dislocations along the grain boundaries were observed in the 3D-printed specimens that explains the increase of yield strength and exceptional plastic behavior of the material.

Similar content being viewed by others

Data availability

The raw/processed data can be provided as request.

References

Kruth J, Mercelis P, Van Vaerenbergh J, Froyen L, Rombouts M (2005) Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp J 11(1):26–36. https://doi.org/10.1108/13552540510573365

Chua CK, Wong CH, Yeong WY (2017) Standards, quality control, and measurement sciences in 3D printing and additive manufacturing. Academic Press is an imprint of Elsevier, London, United Kingdom

Nutt MJ, Winters GL (2003) Stainless steels for medical and surgical applications. ASTM International, West Conshohochen, PA

Joel CN, Sajjad R, Andres T (2019) 2 - Review of additive manufacturing technologies and applications in the aerospace industry. In: Froes F, Boyer R (eds) Additive manufacturing for the aerospace industry. Elsevier, London, United Kingdom, pp 7–31

Kokkinos C, Economou A, Pournara A, Manos A, Spanopoulos I, Kanatzidis M, Tziotzi T, Petkov V, Margariti A, Oikonomopoulos P, Papaefstathiou GS (2020) 3D-printed lab-in-a-syringe voltammetric cell based on a working electrode modified with a highly efficient Ca-MOF sorbent for the determination of Hg (II). Sens Actuators B Chem 321:128508. https://doi.org/10.1016/j.snb.2020.128508

Dilip J, Zhang S, Teng C, Zeng K, Robinson C, Pal D, Stucker B (2017) Influence of processing parameters on the evolution of melt pool, porosity, and microstructures in Ti-6Al-4V alloy parts fabricated by selective laser melting. Prog Addit Manuf 2(3):157–167. https://doi.org/10.1007/s40964-017-0030-2

Kurzynowski T, Gruber K, Stopyra W, Kuźnicka B, Chlebus E (2018) Correlation between process parameters, microstructure and properties of 316L stainless steel processed by selective laser melting. Mater Sci Eng A 718:64–73. https://doi.org/10.1016/j.msea.2018.01.103

Liverani E, Toschi S, Ceschini L, Fortunato A (2017) Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J Mater Process Technol 249:255–263. https://doi.org/10.1016/j.jmatprotec.2017.05.042

Cherry J, Davies H, Mehmood S, Lavery N, Brown S, Sienz J (2015) Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int J Adv Manuf Technol 76(5):869–879. https://doi.org/10.1007/s00170-014-6297-2

Choo H, Sham KL, Bohling J, Ngo A, Xiao X, Ren Y, Depond PJ, Matthews MJ, Garlea E (2019) Effect of laser power on defect, texture, and microstructure of a laser powder bed fusion processed 316L stainless steel. Mater Des 164:1–12. https://doi.org/10.1016/j.matdes.2018.12.006

Zhang M, Sun CN, Zhang X, Goh PC, Wei J, Hardacre D, Li H (2017) Fatigue and fracture behaviour of laser powder bed fusion stainless steel 316L: influence of processing parameters. Mater Sci Eng A 703:251–261. https://doi.org/10.1016/j.msea.2017.07.071

Zhong Y, Liu L, Wikman S, Cui D, Shen Z (2016) Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J Nucl Mater 470:170–178. https://doi.org/10.1016/j.jnucmat.2015.12.034

Qiu C, Kindi MA, Aladawi AS, Hatmi IA (2018) A comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci Rep 8(1):7785–7785. https://doi.org/10.1038/s41598-018-26136-7

Pham Z, Baicheng DL, Coddet C (2013) The study of the laser parameters and environment variables effect on mechanical properties of high compact parts elaborated by selective laser melting 316L powder. Mater Sci Eng A 584:21–31. https://doi.org/10.1016/j.msea.2013.06.055

Di W, Song C, Yang Y, Bai Y (2016) Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater Des 100:291–299. https://doi.org/10.1016/j.matdes.2016.03.111

Röttger A, Boes J, Theisen W et al (2020) Microstructure and mechanical properties of 316L austenitic stainless steel processed by different SLM devices. Int J Adv Manuf Technol 108:769–783. https://doi.org/10.1007/s00170-020-05371-1

Suryawanshi J, Prashanth KG, Ramamurty U (2017) mechanical behavior of selective laser melted 316L stainless steel. Mater Sci Eng A 696:113–121. https://doi.org/10.1016/j.msea.2017.04.058

Casati R, Lemke J, Vedani M (2016) Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J Mater Sci Technol 32(8):738–744. https://doi.org/10.1016/j.jmst.2016.06.016

Lavery N, Cherry J, Mehmood S, Davies H, Girling B, Sackett E, Brown S, Sienz J (2017) Effects of hot isostatic pressing on the elastic modulus and tensile properties of 316L parts made by powder bed laser fusion. Mater Sci Eng A, Struct Mater: Prop, Microstruct Process 693:186–213. https://doi.org/10.1016/j.msea.2017.03.100

Tolosa I, Garciandía F, Zubiri F, Zapirain F, Esnaola A (2010) Study of mechanical properties of AISI 316L stainless steel processed by ‘selective laser melting’, following different manufacturing strategies. Intl J Adv Manuf Technol 51(5):639–647. https://doi.org/10.1007/s00170-010-2631-5

Nguyen QB, Zhu Z, Ng FL, Chua BW, Nai SML, Wei J (2019) High mechanical strengths and ductility of stainless steel 304L fabricated using selective laser melting. J Mater Sci Technol 35(2):388–394. https://doi.org/10.1016/j.jmst.2018.10.013

Bartolomeu F, Buciumeanu M, Pinto E, Alves N, Carvalho O, Silva FS, Miranda G (2017) 316L stainless steel mechanical and tribological behavior—a comparison between selective laser melting, hot pressing and conventional casting. Addit Manuf 16:81–89. https://doi.org/10.1016/j.addma.2017.05.007

Ara I, Azarmi F, Tangpong XW (2021) Microstructure analysis of high-density 316L stainless steel manufactured by selective laser melting process. Metallogr Microstruct Anal 10:754–767. https://doi.org/10.1007/s13632-021-00798-8

Lo YL, Liu BY, Tran HC (2019) Optimized hatch space selection in double-scanning track selective laser melting process. Int J Adv Manuf Technol 105:2989–3006. https://doi.org/10.1007/s00170-019-04456-w

Goodridge R, Ziegelmeier S (2017) 7-Powder bed fusion of polymers. In: Brandt M (ed) Laser additive manufacturing. Woodhead Publishing, Sawston, UK, pp 181–204. https://doi.org/10.1016/B978-0-08-100433-3.00007-5

ASTM E407-07 (2015) Standard Practice for Microetching Metals and Alloys, ASTM International, West Conshohocken, PA

ASTM E112-13 (2013) Standard Test Methods for Determining Average Grain Size, ASTM International, West Conshohocken, PA

ASTM E384 – 17 (2017) Standard Test Method for Microindentation Hardness of Materials, ASTM International, West Conshohocken, PA

ASTM E8/E8M − 16a (2016) Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, PA

ASTM E1876 – 15 (2015) Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration, ASTM International, West Conshohocken, PA

ASTM B311 – 17 (2017) Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity, ASTM Standard, West Conshohocken, PA

Saeidi K, Gao X, Zhong Y, Shen ZJ (2015) Hardened austenite steel with columnar sub-grain structure formed by laser melting. Mater Sci Eng A 625:221–229. https://doi.org/10.1016/j.msea.2014.12.018

Campanelli SL, Contuzzi N, Angelastro A, Ludovico AD (2010) Capabilities and performances of the selective laser melting process. In: Er MJ (ed) New trends in technologies: devices, computer, communication and industrial systems. InTech Europe, Rijeka, Croatia, pp 233–252

Qiu C, Panwisawas C, Ward M, Basoalto HC, Brooks JW, Attallah MM (2015) On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater 96:72–79. https://doi.org/10.1016/j.actamat.2015.06.004

Puichaud AH, Flament C, Chniouel A, Lomello F, Rouesne E, Giroux PF, Maskrot H, Schuster F, Béchade JL (2019) Microstructure and mechanical properties relationship of additively manufactured 316L stainless steel by selective laser melting. EPJ Nucl Sci Technol. https://doi.org/10.1051/epjn/2019051

Shamsujjoha M, Agnew S, Fitz-Gerald J, Moore W, Newman T (2018) High strength and ductility of additively manufactured 316L stainless steel explained. Metall Mater Trans A 49(7):3011–3027. https://doi.org/10.1007/s11661-018-4607-2

Song B, Dong S, Deng S, Liao H, Coddet C (2014) Microstructure and tensile properties of iron parts fabricated by selective laser melting. Opt Laser Technol 56:2014451–2014460. https://doi.org/10.1016/j.optlastec.2013.09.017

Mower TM, Long MJ (2016) Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater Sci Eng: A 651:198–213. https://doi.org/10.1016/j.msea.2015.10.068

Stoll P, Spierings A, Wegener K (2019) Impact of a process interruption on tensile properties of SS 316L parts and hybrid parts produced with selective laser melting. Int J Adv Manuf Technol 103:367–376. https://doi.org/10.1007/s00170-019-03560-1

Spierings AB, Herres N, Levy G (2011) Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp J 17(3):195–202. https://doi.org/10.1108/13552541111124770

Marattukalam JJ, Karlsson D, Pacheco V, Beran P, Wiklund U, Jansson U, Hjörvarsson B, Sahlberg M (2020) The effect of laser scanning strategies on texture, mechanical properties, and site-specific grain orientation in selective laser melted 316L SS. Mater Des 193:108852. https://doi.org/10.1016/j.matdes.2020.108852

Im YD, Kim KH, Jung KH et al (2019) Anisotropic mechanical behavior of additive manufactured AISI 316L steel. Metall Mater Trans A 50:2014–2021. https://doi.org/10.1007/s11661-019-05139-7

Blinn B, Ley M, Buschhorn N, Teutsch R, Beck T (2019) Investigation of the anisotropic fatigue behavior of additively manufactured structures made of AISI 316L with short-time procedures PhyBaLLIT and PhyBaLCHT. Int J Fatigue 124:389–399. https://doi.org/10.1016/j.ijfatigue.2019.03.022

Bahl S, Mishra S, Yazar KU (2019) Immanuel Raju Kola, Kaushik Chatterjee, Satyam Suwas, Non-equilibrium microstructure, crystallographic texture and morphological texture synergistically result in unusual mechanical properties of 3D printed 316L stainless steel. Addit Manuf 28:65–77. https://doi.org/10.1016/j.addma.2019.04.016

Benito JA, Jorba J, Manero JM et al (2005) Change of Young’s modulus of cold-deformed pure iron in a tensile test. Metall Mater Trans A 36:3317–3324. https://doi.org/10.1007/s11661-005-0006-6

Sun Z, Tan X, Tor SB, Yeong WY (2016) Selective laser melting of stainless steel 316l with low porosity and high build rates. Mater Des 104:197–204. https://doi.org/10.1016/j.matdes.2016.05.035

Tucho WM, Cuvillier P, Sjolyst-Kverneland A, Hansen V (2017) Microstructure and hardness studies of inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater Sci Eng A, Struct Mater: Prop, Microstruct Process 689:220–232. https://doi.org/10.1016/j.msea.2017.02.062

Zhang D, Niu W, Cao X, Liu Z (2015) Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater Sci Eng A 644:32–40. https://doi.org/10.1016/j.msea.2015.06.021

Sun Z, Tan X, Tor SB, Chua CK (2018) Simultaneously enhanced strength and ductility for 3D-printed stainless steel 316L by selective laser melting. NPG Asia Mater 10(4):127–136. https://doi.org/10.1038/s41427-018-0018-5

Kong D, Ni X, Dong C, Lei X, Zhang L, Man C, Yao J, Cheng X, Li X (2018) Bio-functional and anti-corrosive 3D printing 316L stainless steel fabricated by selective laser melting mater. Mater Des 152:88–101. https://doi.org/10.1016/j.matdes.2018.04.058

Krakhmalev P, Fredriksson G, Svensson K, Yadroitsev I, Yadroitsava I, Thuvander M, Peng R (2018) Microstructure, solidification texture, and thermal stability of 316L stainless steel manufactured by laser powder bed fusion. Metals 8(8):643. https://doi.org/10.3390/met8080643

Takata N, Nishida R, Suzuki A, Kobashi M, Kato M (2018) Crystallographic features of microstructure in maraging steel fabricated by selective laser melting. Metals 8(6):440. https://doi.org/10.3390/met8060440

Meyers MA, Chawla KK (2009) Mechanical behavior of materials. Cambridge University Press, Cambridge

Wang YM, Voisin T, McKeown JT, Ye J, Calta NP, Li Z, Zeng Z, Zhang Y, Chen W, Roehling TT, Ott RT, Santala MK, Depond PJ, Matthews MJ, Hamza AV, Zhu T (2018) Additively manufactured hierarchical stainless steels with high strength and ductility. Nature Mater 17(1):63–71. https://doi.org/10.1038/nmat5021

Wang Y, Wang YT, Li RD et al (2021) Hall-Petch relationship in selective laser melting additively manufactured metals: using grain or cell size? J Cent South Univ 28:1043–1057. https://doi.org/10.1007/s11771-021-4678-x

Seeger A. (1958) Kristallplastizität. In: Kristallphysik II/Crystal Physics II. Handbuch der Physik/Encyclopedia of Physics 3/7/2. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-45890-3_1

Honeycombe RWK (1984) The Plastic deformation of metals. Edward Arnold Publ, Ltd, London

Kuhlmann-Wilsdorf D (1989) Theory of plastic deformation: -properties of low energy dislocation structures. Mater Sci Eng A 113:1–41. https://doi.org/10.1016/0921-5093(89)90290-6

Acknowledgements

Authors are grateful for valuable help on microstructural characterization using SEM and TEM by NDSU Electron Microscopy Center. FA and IA acknowledge financial support from ND NASA EPSCoR Supplemental Project Funding Award. IS gratefully acknowledges financial support of NASA Cooperative agreement 80NSSC20M0215 to NMSU.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ara, I., Eshkabilov, S., Azarmi, F. et al. Investigation on elastic properties and unconventional plasticity of 316L stainless steel processed by selective laser melting technology. Prog Addit Manuf 7, 1169–1181 (2022). https://doi.org/10.1007/s40964-022-00291-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-022-00291-w