Abstract

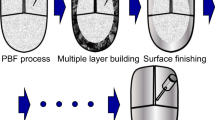

In 3D printing, the highest degree of freedom in design is achieved using powder bed techniques such as selective laser melting (SLM). The current disadvantage of this technique is that it allows only for the production of single material parts using standard setups. However, advanced designs and local requirements are met best by a tailored arrangement of different materials. A key challenge for multi-material powder bed SLM is the selective deposition of the materials in each layer. In this paper, a hybrid-material powder coating system for SLM machines was developed and installed in a SLM125 Realizer machine. First, the generic classification for the material arrangements in additive manufactured parts is reviewed and extended. Furthermore, existing principles and procedures used for multi-material coating, especially focusing on contamination-free processes are examined. Based on this, an advanced coating mechanism is developed and proof of principle is provided.

Similar content being viewed by others

References

Meiners W (1999) Direktes selektives Laser-Sintern einkomponentiger metallischer Werkstoffe. Als Ms. gedr. Berichte aus der Lasertechnik, Shaker, Aachen

Gibson I, Stucker B, Rosen DW (2010) Additive manufacturing technologies: rapid prototyping to direct digital manufacturing. Springer, Boston

Gebhardt A, Hötter J-S (2016) Additive manufacturing: 3D printing for prototyping and manufacturing. Hanser Publications, Munich

Herzog D, Seyda V, Wycisk E et al (2016) Additive manufacturing of metals. Acta Mater 117:371–392. https://doi.org/10.1016/J.ACTAMAT.2016.07.019

DebRoy T, Wei HL, Zuback JS et al (2018) Additive manufacturing of metallic components—process, structure and properties. Prog Mater Sci 92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

Fotovvati B, Namdari N, Dehghanghadikolaei A (2019) Fatigue performance of selective laser melted Ti6Al4 V components: state of the art. Mater Res Express 6(1):12002. https://doi.org/10.1088/2053-1591/aae10e

Shipley H, McDonnell D, Culleton M et al (2018) Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4 V: a review. Int J Mach Tools Manuf 128:1–20. https://doi.org/10.1016/j.ijmachtools.2018.01.003

Lehmhus D, Aumund-Kopp C, Petzoldt F et al (2016) Customized smartness: a survey on links between additive manufacturing and sensor integration. Proc Technol 26:284–301. https://doi.org/10.1016/j.protcy.2016.08.038

Brueckner F, Mirko R, Michael M et al (2017) Fabrication of metallic multi-material components using laser metal deposition (Peer Reviewed)

Vaezi M, Chianrabutra S, Mellor B et al (2013) Multiple material additive manufacturing—part 1: a review. Virtual Phys Prototyp 8(1):19–50. https://doi.org/10.1080/17452759.2013.778175

Ott M (2012) Multimaterialverarbeitung bei der additiven strahl-und pulverbettbasierten Fertigung

Anstaett C, Seidel C, Reinhart G (2017) Fabrication of 3D multi-material parts using laser-based powder bed fusion. Proc Solid Freeform Fabr Symp 28:1548–1556

Al-Jamal OM, Hinduja S, Li L (2008) Characteristics of the bond in Cu–H13 tool steel parts fabricated using SLM. CIRP Ann 57(1):239–242. https://doi.org/10.1016/j.cirp.2008.03.010

Anstaett C, Schafnitzel M, Seidel C et al (2017) Laser-based powder bed fusion of 3D-Multi-material-parts of copper-chrome-zirconia and tool steel

Kellner IN (2013) Materialsysteme für das pulverbettbasierte 3D-Drucken. Herbert Utz Verlag

Lu X, Yang S, Evans JRG (2009) Microfeeding with different ultrasonic nozzle designs. Ultrasonics 49(6–7):514–521. https://doi.org/10.1016/j.ultras.2009.01.003

Stichel T, Laumer T, Wittmann P et al (2015) Selective deposition of polymer powder by vibrating nozzles for laser beam melting. In: Proceedings of lasers in manufacturing conference

Koopmann J, Voigt J, Niendorf T (2019) Additive manufacturing of a steel-ceramic multi-material by selective laser melting. Metal Mater Trans B. https://doi.org/10.1007/s11663-019-01523-1

Binder M, Anstaett C, Reisch R et al (2018) Automated manufacturing of mechatronic parts by laser-based powder bed fusion. Proc Manuf 18:12–19. https://doi.org/10.1016/j.promfg.2018.11.002

Chianrabutra S, Mellor BG, Yang S (2014) A dry powder material delivery device for multiple material additive manufacturing. Proc SFF Symp 25:36–48

Stichel T, Laumer T, Baumüller T et al (2014) Powder layer preparation using vibration-controlled capillary steel nozzles for additive manufacturing. Phys Proc 56:157–166. https://doi.org/10.1016/j.phpro.2014.08.158

Jones JB (2013) Investigation of laser printing for 3D printing and additive manufacturing. PhD thesis, University of Warwick. http://wrap.warwick.ac.uk/59733/

Lappo K, Wood K, Bourell D et al (2003) Discrete multiple material selective laser sintering (M2SLS): experimental study of part processing. Proc SFF Symp 109:109–119

Lappo K, Wood K, Bourell D et al (2003) Discrete multiple material selective laser sintering (M2SLS): nozzle design for powder delivery. Proc SFF Symp 109:93–108

Jasion GT, Shrimpton JS, Li Z et al (2013) On the bridging mechanism in vibration controlled dispensing of pharmaceutical powders from a micro hopper. Powder Technol 249:24–37. https://doi.org/10.1016/j.powtec.2013.07.027

Jiang Y, Matsusaka S, Masuda H et al (2009) Development of measurement system for powder flowability based on vibrating capillary method. Powder Technol 188(3):242–247. https://doi.org/10.1016/j.powtec.2008.05.003

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest associated with this script.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Girnth, S., Koopmann, J., Klawitter, G. et al. 3D hybrid-material processing in selective laser melting: implementation of a selective coating system. Prog Addit Manuf 4, 399–409 (2019). https://doi.org/10.1007/s40964-019-00082-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40964-019-00082-w